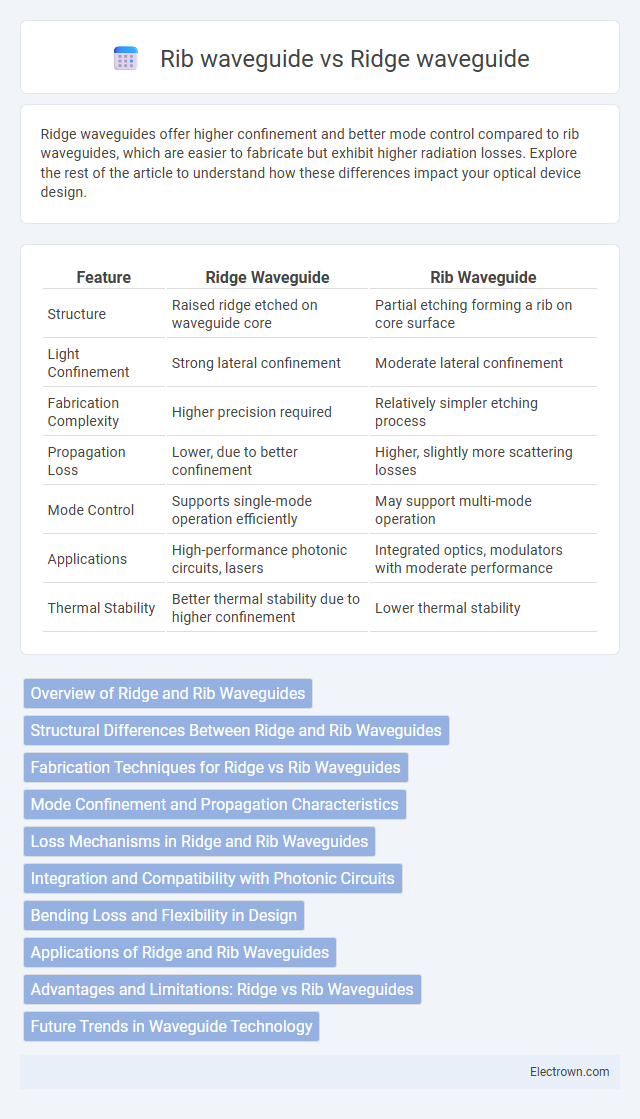

Ridge waveguides offer higher confinement and better mode control compared to rib waveguides, which are easier to fabricate but exhibit higher radiation losses. Explore the rest of the article to understand how these differences impact your optical device design.

Table of Comparison

| Feature | Ridge Waveguide | Rib Waveguide |

|---|---|---|

| Structure | Raised ridge etched on waveguide core | Partial etching forming a rib on core surface |

| Light Confinement | Strong lateral confinement | Moderate lateral confinement |

| Fabrication Complexity | Higher precision required | Relatively simpler etching process |

| Propagation Loss | Lower, due to better confinement | Higher, slightly more scattering losses |

| Mode Control | Supports single-mode operation efficiently | May support multi-mode operation |

| Applications | High-performance photonic circuits, lasers | Integrated optics, modulators with moderate performance |

| Thermal Stability | Better thermal stability due to higher confinement | Lower thermal stability |

Overview of Ridge and Rib Waveguides

Ridge waveguides feature a raised strip etched on a planar substrate, providing strong optical confinement with low propagation loss, widely used in integrated photonics for efficient light guiding. Rib waveguides consist of a partially etched ridge that forms a slab-like structure, balancing moderate confinement and easier fabrication suitable for optical communication applications. Both waveguide types play crucial roles in silicon photonics, offering distinct trade-offs between optical confinement, fabrication complexity, and performance.

Structural Differences Between Ridge and Rib Waveguides

Ridge waveguides feature a raised strip etched into the top layer of the substrate, providing strong optical confinement by altering the waveguide's width and height. Rib waveguides have a partially etched top layer forming a "rib" structure, offering moderate confinement with a balance between single-mode propagation and fabrication tolerance. Your choice depends on the required optical confinement and fabrication constraints related to these structural differences.

Fabrication Techniques for Ridge vs Rib Waveguides

Ridge waveguides are typically fabricated using precision etching methods, such as reactive ion etching (RIE), to create a raised strip on the substrate that confines light effectively. Rib waveguides use partial etching processes where only a shallow section of the waveguide layer is etched, maintaining a slab underneath that supports better mode confinement and reduced scattering losses. The fabrication of rib waveguides generally requires more controlled etch depth and uniformity, resulting in improved tolerance to fabrication variations compared to ridge waveguides.

Mode Confinement and Propagation Characteristics

Ridge waveguides provide stronger mode confinement due to their higher refractive index contrast and fully etched geometry, resulting in lower bending losses and better performance in compact photonic circuits. Rib waveguides offer moderate mode confinement with partial etching, producing lower scattering losses and simpler fabrication, suitable for longer propagation distances where minimal loss is critical. Your choice depends on balancing confinement needs for dense integration (ridge) against propagation efficiency for extended waveguide lengths (rib).

Loss Mechanisms in Ridge and Rib Waveguides

Loss mechanisms in ridge waveguides primarily arise from sidewall roughness scattering and absorption at the etched vertical sidewalls, leading to higher propagation losses compared to rib waveguides. Rib waveguides exhibit lower loss due to reduced etching depth, minimizing sidewall roughness and mode leakage while maintaining sufficient optical confinement. Both waveguide types experience bending loss and substrate leakage, but rib waveguides generally offer superior performance in low-loss photonic circuit applications.

Integration and Compatibility with Photonic Circuits

Ridge waveguides offer superior integration and compatibility with photonic circuits due to their higher modal confinement and lower scattering losses, enabling denser circuit layouts and efficient coupling with active components. Rib waveguides provide easier fabrication and better mode matching with optical fibers, making them suitable for applications requiring seamless integration with existing fiber-optic systems. Both waveguide types are compatible with silicon photonics platforms, but ridge waveguides are preferred for high-performance, compact photonic integrated circuits.

Bending Loss and Flexibility in Design

Ridge waveguides exhibit lower bending loss due to their strong mode confinement, enabling tighter bends with minimal signal degradation, making them ideal for compact photonic circuits. Rib waveguides offer greater flexibility in design by allowing easier fabrication of variable cross-sections and integration with other components, though they experience higher bending loss in sharp turns. Your choice depends on whether minimizing bending loss or achieving versatile, flexible layouts is the priority for your photonic device.

Applications of Ridge and Rib Waveguides

Ridge waveguides are widely utilized in high-power laser systems and optical amplifiers due to their strong mode confinement and efficient heat dissipation. Rib waveguides find significant applications in integrated photonic circuits, including modulators and sensors, where low propagation loss and compatibility with planar fabrication processes are essential. Both structures play critical roles in telecommunications and on-chip optical interconnects, leveraging their distinct advantages in mode control and device integration.

Advantages and Limitations: Ridge vs Rib Waveguides

Ridge waveguides offer higher optical confinement and lower propagation losses compared to rib waveguides, making them ideal for high-performance photonic integrated circuits. However, rib waveguides provide easier fabrication and better mechanical stability, which can be advantageous for cost-effective mass production. Your choice depends on whether performance or manufacturability is the priority in your photonic design.

Future Trends in Waveguide Technology

Advancements in ridge waveguide technology emphasize enhanced mode confinement and reduced scattering losses, driving innovation in high-speed optical communication systems. Rib waveguides, benefiting from simpler fabrication and improved integration with photonic circuits, are increasingly favored for compact, low-cost on-chip applications. Future trends point to hybrid designs combining ridge and rib features to optimize performance for next-generation photonic integrated circuits and quantum computing platforms.

Ridge waveguide vs Rib waveguide Infographic

electrown.com

electrown.com