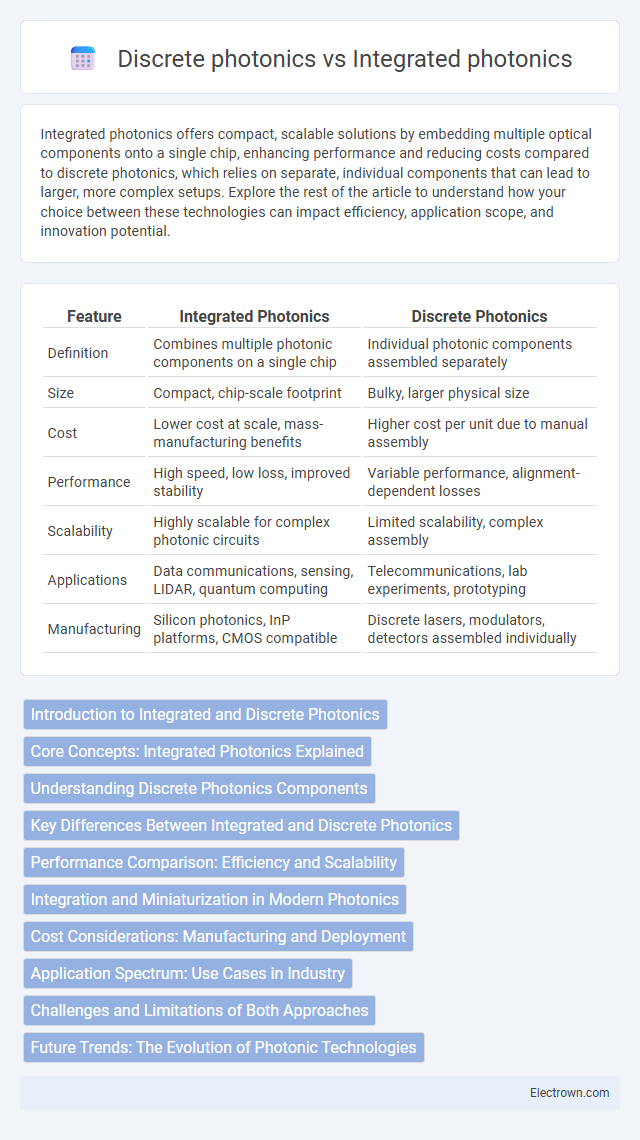

Integrated photonics offers compact, scalable solutions by embedding multiple optical components onto a single chip, enhancing performance and reducing costs compared to discrete photonics, which relies on separate, individual components that can lead to larger, more complex setups. Explore the rest of the article to understand how your choice between these technologies can impact efficiency, application scope, and innovation potential.

Table of Comparison

| Feature | Integrated Photonics | Discrete Photonics |

|---|---|---|

| Definition | Combines multiple photonic components on a single chip | Individual photonic components assembled separately |

| Size | Compact, chip-scale footprint | Bulky, larger physical size |

| Cost | Lower cost at scale, mass-manufacturing benefits | Higher cost per unit due to manual assembly |

| Performance | High speed, low loss, improved stability | Variable performance, alignment-dependent losses |

| Scalability | Highly scalable for complex photonic circuits | Limited scalability, complex assembly |

| Applications | Data communications, sensing, LIDAR, quantum computing | Telecommunications, lab experiments, prototyping |

| Manufacturing | Silicon photonics, InP platforms, CMOS compatible | Discrete lasers, modulators, detectors assembled individually |

Introduction to Integrated and Discrete Photonics

Integrated photonics involves fabricating multiple photonic components such as lasers, modulators, and detectors on a single chip, offering enhanced miniaturization and improved performance for applications like optical communication and sensing. Discrete photonics relies on separate, individual components interconnected by optical fibers or free space, providing flexibility but often leading to larger size, higher cost, and increased insertion loss. Advances in silicon photonics have accelerated the adoption of integrated photonics by enabling mass production and compatibility with existing semiconductor manufacturing processes.

Core Concepts: Integrated Photonics Explained

Integrated photonics involves embedding multiple photonic functions, such as lasers, modulators, and detectors, onto a single chip, significantly enhancing compactness and performance. Discrete photonics relies on separate, individual components interconnected by fibers or waveguides, which can increase system complexity and size. Your choice between these technologies impacts system integration, scalability, and cost efficiency in optical communication and sensing applications.

Understanding Discrete Photonics Components

Discrete photonics components are individual optical devices such as lasers, modulators, detectors, and waveguides that operate independently and are typically assembled on separate substrates. These components offer high performance and customization but often face challenges related to size, alignment, and scalability compared to integrated photonics. Understanding discrete photonics is essential for designing optical systems where precise control and specialized functionality are required before transitioning to compact, integrated solutions.

Key Differences Between Integrated and Discrete Photonics

Integrated photonics combines multiple optical components on a single chip, enabling compact, efficient, and scalable light manipulation systems, while discrete photonics relies on separate, individual optical devices assembled in a larger setup. Integrated photonics offers faster signal processing, lower loss, and improved stability, making it ideal for applications such as telecommunications, data centers, and sensors, unlike discrete photonics, which excels in flexibility and customization for experimental or specialized uses. Understanding these key differences helps optimize Your choice of photonic technology for specific performance, size, and cost requirements.

Performance Comparison: Efficiency and Scalability

Integrated photonics offers superior efficiency through reduced optical losses and enhanced signal integrity by minimizing interconnect distances compared to discrete photonics. Scalability is significantly improved in integrated photonics due to the monolithic integration of multiple photonic components on a single chip, enabling high-volume manufacturing and compact system design. In contrast, discrete photonics faces challenges in scalability and efficiency because of larger footprints, increased alignment complexity, and higher coupling losses between separate components.

Integration and Miniaturization in Modern Photonics

Integrated photonics enables the miniaturization of optical components by embedding multiple photonic functions onto a single chip, significantly reducing size and power consumption compared to discrete photonics, which relies on separate optical elements assembled externally. This integration facilitates enhanced performance, scalability, and cost-effectiveness in applications such as data communications, sensing, and quantum computing. Advances in materials like silicon photonics and fabrication techniques drive the rapid development of highly compact, complex photonic circuits surpassing the limitations of traditional discrete setups.

Cost Considerations: Manufacturing and Deployment

Integrated photonics offers significant cost advantages over discrete photonics by enabling mass production on semiconductor fabrication lines, reducing material waste and assembly time. Manufacturing integrated photonic circuits leverages established CMOS processes, lowering per-unit costs and enhancing scalability compared to the manual and labor-intensive assembly of discrete components. Your choice impacts long-term deployment expenses, with integrated photonics providing more efficient supply chains and simplified system integration.

Application Spectrum: Use Cases in Industry

Integrated photonics offers a broad application spectrum in telecommunications, data centers, and sensing technologies due to its compact size and energy efficiency. Discrete photonics remains essential in specialized industrial equipment, high-power laser applications, and optical instrumentation requiring individual component customization. The industry leverages integrated photonics for scalable mass production and discrete photonics for precision-driven tasks in aerospace, defense, and medical devices.

Challenges and Limitations of Both Approaches

Integrated photonics faces challenges such as complex fabrication processes and thermal management issues, limiting scalability and performance consistency. Discrete photonics struggles with alignment precision and bulkiness, making system integration and miniaturization difficult. Your choice between these approaches depends on balancing integration complexity against modular flexibility for specific applications.

Future Trends: The Evolution of Photonic Technologies

Integrated photonics is rapidly advancing due to its ability to miniaturize optical components onto a single chip, offering higher performance, lower power consumption, and cost-effective scalability compared to discrete photonics. Future trends emphasize the integration of electronic and photonic circuits, enabling more complex functionalities in telecommunications, data centers, and sensing applications. Your technology investments will benefit from the shift toward integrated photonics as it drives innovation in high-speed data transmission and quantum computing.

Integrated photonics vs Discrete photonics Infographic

electrown.com

electrown.com