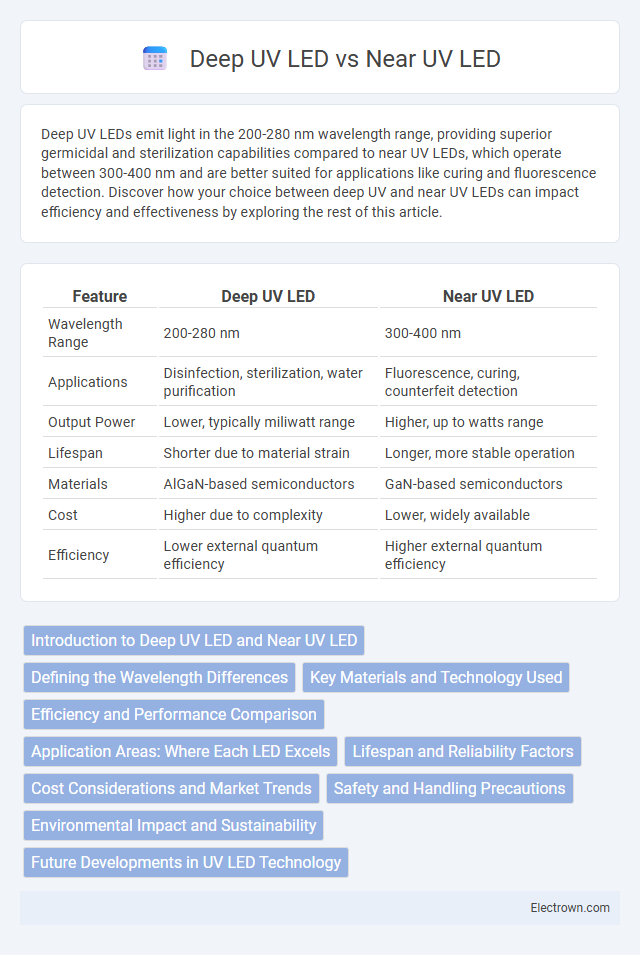

Deep UV LEDs emit light in the 200-280 nm wavelength range, providing superior germicidal and sterilization capabilities compared to near UV LEDs, which operate between 300-400 nm and are better suited for applications like curing and fluorescence detection. Discover how your choice between deep UV and near UV LEDs can impact efficiency and effectiveness by exploring the rest of this article.

Table of Comparison

| Feature | Deep UV LED | Near UV LED |

|---|---|---|

| Wavelength Range | 200-280 nm | 300-400 nm |

| Applications | Disinfection, sterilization, water purification | Fluorescence, curing, counterfeit detection |

| Output Power | Lower, typically miliwatt range | Higher, up to watts range |

| Lifespan | Shorter due to material strain | Longer, more stable operation |

| Materials | AlGaN-based semiconductors | GaN-based semiconductors |

| Cost | Higher due to complexity | Lower, widely available |

| Efficiency | Lower external quantum efficiency | Higher external quantum efficiency |

Introduction to Deep UV LED and Near UV LED

Deep UV LEDs emit ultraviolet light in the 200-280 nm range, offering strong germicidal properties essential for sterilization and disinfection applications. Near UV LEDs operate within the 300-400 nm wavelength range, commonly used for curing, fluorescence, and counterfeit detection due to their efficient energy output and safety profile. Your selection between Deep UV and Near UV LEDs depends on the specific wavelength requirements and end-use applications requiring precise UV light spectrum.

Defining the Wavelength Differences

Deep UV LEDs emit light wavelengths typically ranging from 200 to 280 nanometers, targeting applications like sterilization and pathogen detection due to their strong germicidal properties. Near UV LEDs operate within the 300 to 400 nanometers spectrum, commonly used for curing adhesives, counterfeit detection, and fluorescence excitation. The clear demarcation in wavelength bands between Deep UV and Near UV LEDs directly influences their effectiveness and suitability for specific industrial and biomedical applications.

Key Materials and Technology Used

Deep UV LEDs primarily use aluminum gallium nitride (AlGaN) semiconductor materials, enabling emission in the 200-280 nm wavelength range essential for sterilization and water purification. Near UV LEDs are typically based on indium gallium nitride (InGaN) alloys, emitting light in the 300-400 nm range, suitable for curing and counterfeit detection applications. Advanced epitaxial growth techniques and substrate materials like sapphire or silicon carbide optimize efficiency and lifetime for both LED types.

Efficiency and Performance Comparison

Deep UV LEDs typically operate within the 200-280 nm wavelength range, offering higher photon energy essential for sterilization and disinfection applications but often exhibit lower external quantum efficiency (EQE) due to material challenges and higher defect densities. Near UV LEDs, spanning 300-400 nm wavelengths, achieve higher efficiencies and longer lifetimes, benefiting from more mature semiconductor technologies and optimized thermal management, which translates to better overall performance in applications like curing and sensing. The trade-off between Deep UV and Near UV LEDs centers on balancing wavelength specificity against operational efficiency and device reliability, influencing the choice based on application requirements.

Application Areas: Where Each LED Excels

Deep UV LEDs excel in sterilization, water purification, and medical diagnostics due to their ability to emit light below 280 nm, effectively destroying harmful microorganisms. Near UV LEDs, typically emitting between 365-405 nm, are widely used in curing adhesives, counterfeit detection, and fluorescence excitation, offering safer handling and broader material compatibility. Your choice depends on the specific wavelength requirements and application areas, balancing performance with safety considerations.

Lifespan and Reliability Factors

Deep UV LEDs generally have a shorter lifespan compared to Near UV LEDs due to higher energy emissions causing faster material degradation. Factors affecting their reliability include operating temperature, current density, and packaging quality, with Deep UV LEDs demanding more stringent thermal management to maintain performance. Your choice between the two should consider these durability aspects to ensure optimal device longevity for your specific application.

Cost Considerations and Market Trends

Deep UV LEDs typically incur higher production costs due to complex semiconductor materials like AlGaN and lower manufacturing yields, leading to elevated prices compared to Near UV LEDs, which use more mature and cost-effective GaN technology. Market trends indicate growing demand for Deep UV LEDs in sterilization and water purification, driving investments that may reduce costs over time, while Near UV LEDs dominate applications such as counterfeit detection and curing processes due to their affordability and established supply chains. Cost considerations remain critical as economies of scale and technological advancements gradually narrow the price gap between these two UV LED types.

Safety and Handling Precautions

Deep UV LEDs, emitting wavelengths below 280 nm, pose higher risks of skin and eye damage due to their higher photon energy, necessitating stringent safety measures such as protective goggles and limited exposure time. Near UV LEDs, typically emitting between 300-400 nm, have lower energy and are generally safer but still require caution to avoid prolonged direct eye exposure or skin contact. Proper handling protocols, including the use of UV-blocking shields and adherence to exposure limits established by organizations like OSHA and ICNIRP, are essential for both Deep and Near UV LED applications.

Environmental Impact and Sustainability

Deep UV LEDs offer significant environmental advantages over near UV LEDs, as they operate at lower power levels and generate less heat, reducing energy consumption and carbon footprint. Their longer lifespan minimizes electronic waste, while near UV LEDs often require more frequent replacement due to higher thermal degradation. Choosing Deep UV LEDs for your applications supports sustainability by conserving energy and lowering hazardous waste output.

Future Developments in UV LED Technology

Future developments in UV LED technology emphasize enhanced efficiency and wavelength precision in Deep UV LEDs (wavelengths < 280 nm) for applications like water purification and sterilization, outperforming Near UV LEDs (wavelengths 300-400 nm) in germicidal effectiveness. Innovations in materials such as aluminum nitride (AlN) and improvements in epitaxial growth techniques aim to overcome current limitations like low external quantum efficiency and device reliability in Deep UV LEDs. Near UV LED advancements focus on cost reduction and integration into consumer electronics, but Deep UV LED breakthroughs are expected to drive industrial and medical disinfection markets.

Deep UV LED vs Near UV LED Infographic

electrown.com

electrown.com