Series LED connections ensure the same current flows through each LED, providing uniform brightness but requiring higher voltage as more LEDs are added; parallel LED setups allow independent operation of each LED at the same voltage but demand careful current regulation to prevent overheating. Explore the rest of the article to understand which configuration suits Your electronic projects best.

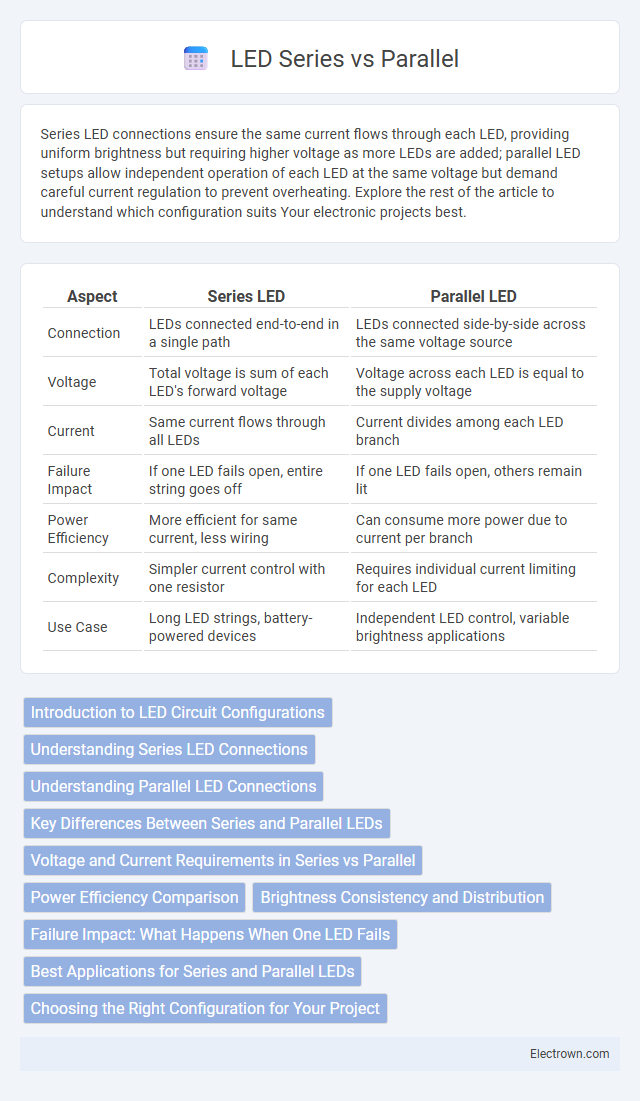

Table of Comparison

| Aspect | Series LED | Parallel LED |

|---|---|---|

| Connection | LEDs connected end-to-end in a single path | LEDs connected side-by-side across the same voltage source |

| Voltage | Total voltage is sum of each LED's forward voltage | Voltage across each LED is equal to the supply voltage |

| Current | Same current flows through all LEDs | Current divides among each LED branch |

| Failure Impact | If one LED fails open, entire string goes off | If one LED fails open, others remain lit |

| Power Efficiency | More efficient for same current, less wiring | Can consume more power due to current per branch |

| Complexity | Simpler current control with one resistor | Requires individual current limiting for each LED |

| Use Case | Long LED strings, battery-powered devices | Independent LED control, variable brightness applications |

Introduction to LED Circuit Configurations

LED circuit configurations include series and parallel setups, each influencing current flow and voltage requirements differently. In a series circuit, LEDs share the same current but the voltage divides across each LED, which demands a voltage equal to the sum of all individual LED forward voltages. Parallel circuits ensure each LED receives the full source voltage independently, requiring current to divide among the LEDs for consistent brightness and performance.

Understanding Series LED Connections

Series LED connections involve linking LEDs end-to-end so the same current flows through each LED, resulting in a cumulative voltage drop equal to the sum of individual LED voltage drops. This setup simplifies wiring and reduces current requirements but requires a higher voltage power source to overcome the total forward voltage. Your choice of series configuration affects brightness uniformity and power efficiency, making it essential to calculate total voltage and current for optimal LED performance.

Understanding Parallel LED Connections

Parallel LED connections involve wiring each LED directly to the power source, ensuring uniform voltage across all LEDs while allowing independent operation. This configuration prevents the failure of one LED from affecting others, making it ideal for applications requiring consistent brightness and reliability. Parallel circuits require careful consideration of current distribution and may need individual resistors to protect each LED from current fluctuations.

Key Differences Between Series and Parallel LEDs

Series LEDs share the same current, with voltage dividing across each LED, which can cause brightness to decrease if one LED fails. Parallel LEDs have the same voltage across each LED, allowing individual operation without affecting the others, though current draws increase with more LEDs. To optimize your LED circuit, choose series for consistent current and parallel for independent LED control.

Voltage and Current Requirements in Series vs Parallel

LEDs connected in series require a voltage equal to the sum of each LED's forward voltage, while current remains constant throughout the circuit. In contrast, parallel LED configurations maintain a voltage equal to a single LED's forward voltage but demand a total current equal to the sum of all individual LEDs' currents. Understanding these voltage and current requirements helps you design efficient LED circuits tailored to your project's power supply capabilities.

Power Efficiency Comparison

Series LED configurations offer higher power efficiency by maintaining a constant current through all LEDs, reducing energy loss and heat generation compared to parallel setups. Parallel LED arrangements cause uneven current distribution, leading to increased power consumption and potential brightness inconsistency. Optimizing Your lighting system with series wiring minimizes energy waste and extends LED lifespan.

Brightness Consistency and Distribution

Series LEDs provide uniform brightness across all LEDs because the same current flows through each diode, ensuring consistent illumination throughout the circuit. In parallel LED configurations, brightness can vary for each LED depending on individual current draw and voltage drops, potentially causing uneven light distribution. Your choice between series and parallel setups impacts the overall lighting uniformity and efficiency of your LED array.

Failure Impact: What Happens When One LED Fails

In a series LED circuit, when one LED fails open, the entire string stops functioning because the current flow is interrupted. In contrast, parallel LED circuits continue operating even if one LED fails, as each LED has an independent current path. However, parallel configurations may require additional current regulation to prevent uneven brightness and potential damage to remaining LEDs.

Best Applications for Series and Parallel LEDs

Series LEDs are ideal for applications requiring consistent current flow and uniform brightness, such as LED strips in lighting fixtures or decorative displays, ensuring each diode receives the same current. Parallel LEDs excel in situations demanding independent operation of individual diodes, like indicator panels or customizable lighting systems, because each LED receives the full voltage and operates independently. Your choice between series and parallel configurations depends on whether you prioritize uniform brightness and simplicity (series) or flexibility and individual control (parallel).

Choosing the Right Configuration for Your Project

Selecting the optimal LED configuration depends on voltage requirements and current stability, with series connections offering uniform current flow and lower voltage drop per LED, ideal for low-voltage applications. Parallel LED setups maintain consistent voltage across each LED, making them suitable for high-voltage environments and scenarios needing individual LED control. Evaluating power sources, desired brightness, and safety margins ensures efficient and reliable LED performance tailored to your project.

Series LED vs Parallel LED Infographic

electrown.com

electrown.com