Oxide-confined VCSELs offer superior current confinement and thermal management, resulting in higher power efficiency and reliability compared to ion-implanted VCSELs, which typically have simpler fabrication but suffer from increased electrical resistance and lower efficiency. Discover how your choice between these VCSEL types impacts device performance and applications by reading the full article.

Table of Comparison

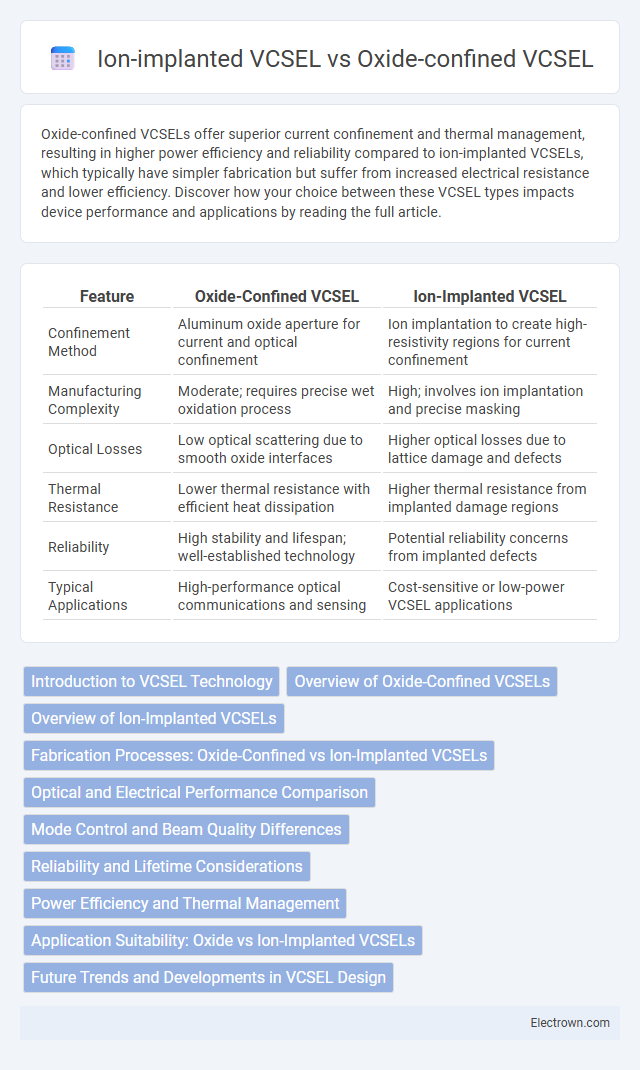

| Feature | Oxide-Confined VCSEL | Ion-Implanted VCSEL |

|---|---|---|

| Confinement Method | Aluminum oxide aperture for current and optical confinement | Ion implantation to create high-resistivity regions for current confinement |

| Manufacturing Complexity | Moderate; requires precise wet oxidation process | High; involves ion implantation and precise masking |

| Optical Losses | Low optical scattering due to smooth oxide interfaces | Higher optical losses due to lattice damage and defects |

| Thermal Resistance | Lower thermal resistance with efficient heat dissipation | Higher thermal resistance from implanted damage regions |

| Reliability | High stability and lifespan; well-established technology | Potential reliability concerns from implanted defects |

| Typical Applications | High-performance optical communications and sensing | Cost-sensitive or low-power VCSEL applications |

Introduction to VCSEL Technology

Oxide-confined VCSELs utilize selective oxidation of AlGaAs layers to create a current aperture, providing low threshold currents and high efficiency in vertical-cavity surface-emitting lasers. Ion-implanted VCSELs achieve current confinement by introducing high-energy ions to form an insulating region, allowing precise control over current flow and device characteristics. Your choice between these technologies depends on factors like fabrication complexity, device performance, and thermal management requirements in applications such as data communication and sensing.

Overview of Oxide-Confined VCSELs

Oxide-confined VCSELs utilize a selectively oxidized AlGaAs layer to create a high-refractive-index contrast, enabling efficient current and optical mode confinement within the laser cavity. This design enhances modal stability and reduces threshold current, resulting in improved device performance and reliability compared to ion-implanted VCSELs. Your selection of oxide-confined VCSELs benefits from superior thermal management and scalability for high-speed optical communication applications.

Overview of Ion-Implanted VCSELs

Ion-implanted VCSELs use ion implantation to create current apertures by damaging and thus electrically isolating regions outside the active area, enabling precise control of current flow and reducing parasitic capacitance. This method offers advantages in fabrication simplicity and device reliability over oxide-confined VCSELs that rely on selective oxidation of AlGaAs layers to define the current aperture. Your choice between ion-implanted and oxide-confined VCSELs depends on factors like desired device performance, fabrication complexity, and thermal management.

Fabrication Processes: Oxide-Confined vs Ion-Implanted VCSELs

Oxide-confined VCSELs utilize selective wet oxidation of high-aluminum-content AlGaAs layers to create a current aperture that confines both current and optical modes, enabling low threshold currents and high efficiency. Ion-implanted VCSELs employ high-energy ion implantation to create insulating regions within the semiconductor, defining the current aperture with precise lateral confinement but often involving complex masking and annealing steps. The oxide-confined process generally offers better device uniformity and thermal stability, while ion implantation allows for more flexible aperture patterning but can introduce defects that affect device performance.

Optical and Electrical Performance Comparison

Oxide-confined VCSELs typically exhibit lower threshold currents and higher differential quantum efficiency due to their effective current and optical mode confinement, resulting in output powers exceeding several milliwatts with stable single-mode operation. Ion-implanted VCSELs offer improved electrical isolation and reduced parasitic capacitance, enabling higher modulation speeds but often suffer from increased optical losses and higher threshold currents compared to oxide-confined devices. The trade-off between electrical performance and optical efficiency makes oxide-confined VCSELs preferable for low-power, high-brightness applications, while ion-implanted VCSELs suit high-speed data communication where modulation bandwidth is critical.

Mode Control and Beam Quality Differences

Oxide-confined VCSELs exhibit superior mode control due to their well-defined current aperture formed by selective oxidation, resulting in stable single-mode operation and high beam quality with low divergence. Ion-implanted VCSELs rely on ion implantation to create a resistive region that confines current, which can lead to less precise mode control and higher likelihood of multimode emission, causing degraded beam quality and increased divergence. The precise aperture in oxide-confined designs ensures more uniform current distribution and reduced modal competition compared to the more diffused current blocking in ion-implanted VCSELs.

Reliability and Lifetime Considerations

Oxide-confined VCSELs exhibit superior reliability and longer operational lifetimes compared to ion-implanted VCSELs due to their stable oxide aperture, which reduces current crowding and thermal degradation. Ion-implanted VCSELs, while offering precise current confinement, often face reliability challenges stemming from implantation-induced defects that can accelerate device aging and performance deterioration. Long-term studies indicate oxide-confined VCSELs maintain consistent optical output and threshold current levels over extended periods, making them preferable for high-reliability applications.

Power Efficiency and Thermal Management

Oxide-confined VCSELs exhibit higher power efficiency due to better current aperture control, resulting in lower threshold current and reduced power consumption compared to ion-implanted VCSELs. Thermal management in oxide-confined VCSELs is enhanced by the oxide layer's superior heat conduction properties, enabling more effective dissipation of heat during operation. Ion-implanted VCSELs often face challenges in thermal conductivity and power efficiency due to implantation-induced defects that increase resistive heating and decrease overall device performance.

Application Suitability: Oxide vs Ion-Implanted VCSELs

Oxide-confined VCSELs offer superior performance for high-speed data communication and sensing applications due to their low threshold current and high modulation bandwidth. Ion-implanted VCSELs, with their precise current confinement and better thermal stability, are more suitable for applications requiring robust operation in harsh environments, such as industrial and automotive sectors. Your choice depends on whether you prioritize speed and efficiency or durability and environmental resilience.

Future Trends and Developments in VCSEL Design

Future trends in VCSEL design emphasize enhanced performance through novel oxide-confined structures that offer superior current confinement and thermal management compared to ion-implanted VCSELs, which are limited by increased series resistance and reduced reliability. Research is advancing toward integrating high-speed modulation capabilities and wavelength tuning in oxide-confined VCSELs to meet the demands of data communication and sensing applications. Your choice of VCSEL technology will benefit from ongoing developments prioritizing efficiency, scalability, and integration with photonic circuits.

Oxide-confined VCSEL vs Ion-implanted VCSEL Infographic

electrown.com

electrown.com