Open-loop control operates without feedback, relying solely on predefined inputs to manage system behavior, while closed-loop control continuously monitors output and adjusts inputs for optimal performance and accuracy. Discover how understanding the differences between these control methods can enhance Your system's efficiency by reading the rest of this article.

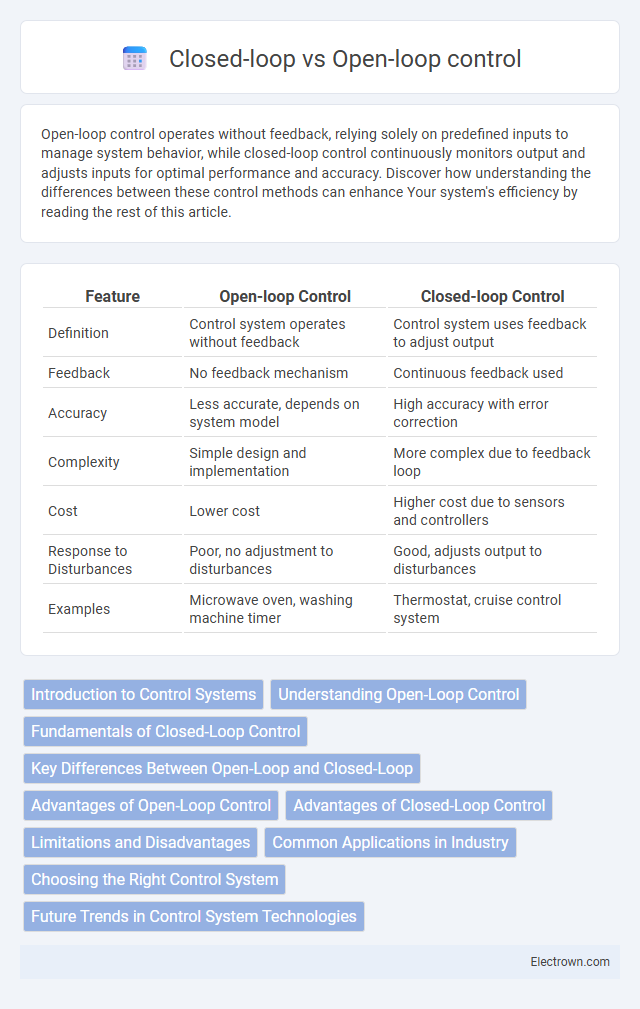

Table of Comparison

| Feature | Open-loop Control | Closed-loop Control |

|---|---|---|

| Definition | Control system operates without feedback | Control system uses feedback to adjust output |

| Feedback | No feedback mechanism | Continuous feedback used |

| Accuracy | Less accurate, depends on system model | High accuracy with error correction |

| Complexity | Simple design and implementation | More complex due to feedback loop |

| Cost | Lower cost | Higher cost due to sensors and controllers |

| Response to Disturbances | Poor, no adjustment to disturbances | Good, adjusts output to disturbances |

| Examples | Microwave oven, washing machine timer | Thermostat, cruise control system |

Introduction to Control Systems

Open-loop control systems operate without feedback, where the output is independent of the input or system states, making them simpler but less accurate in handling disturbances. Closed-loop control systems utilize feedback to continuously adjust the control input based on the output, enhancing precision and stability in dynamic environments. Understanding these differences helps you design more effective control systems tailored to specific application requirements.

Understanding Open-Loop Control

Open-loop control systems operate without feedback, relying solely on predefined input commands to execute tasks, making them simpler and faster but less accurate. These systems are ideal for applications where the environment is predictable, such as timed washing machines or traffic lights. You can optimize open-loop control by ensuring precise input calibration and system modeling to minimize errors in the absence of real-time adjustments.

Fundamentals of Closed-Loop Control

Closed-loop control systems rely on feedback from sensors to continuously monitor and adjust the output, ensuring accurate and stable performance. The system compares the actual output to the desired setpoint, calculating the error and using it to modify the control input dynamically. This feedback mechanism improves precision, reduces sensitivity to disturbances, and enhances system reliability in applications like temperature regulation, robotics, and industrial automation.

Key Differences Between Open-Loop and Closed-Loop

Open-loop control systems operate without feedback, relying solely on predefined inputs to achieve the desired output, making them simpler but less accurate. Closed-loop control systems continuously monitor output through feedback sensors, enabling real-time adjustments to maintain precision and compensate for disturbances. The key difference lies in feedback presence: open-loop lacks it, resulting in potential errors, whereas closed-loop utilizes feedback for adaptive control and enhanced accuracy.

Advantages of Open-Loop Control

Open-loop control systems offer simplicity and cost-effectiveness due to the absence of feedback mechanisms, making them easier to design and maintain. They provide fast response times since control actions are executed without waiting for system output measurements. Open-loop control is ideal for applications where system behavior is predictable and disturbances are minimal, ensuring reliable and consistent performance.

Advantages of Closed-Loop Control

Closed-loop control systems offer precise regulation by continuously monitoring output and adjusting inputs to maintain desired performance despite disturbances. You benefit from enhanced accuracy, stability, and adaptability in processes such as temperature regulation, motor speed control, and robotic automation. These systems reduce errors and improve efficiency compared to open-loop control which lacks feedback mechanisms.

Limitations and Disadvantages

Open-loop control systems lack feedback mechanisms, making them unable to correct errors or adapt to disturbances, which often results in reduced accuracy and reliability. Closed-loop control systems can encounter issues such as increased complexity, higher costs, and potential instability due to the feedback loop. Both systems face limitations in environments with unpredictable changes, but closed-loop control generally offers better performance through dynamic adjustment despite these challenges.

Common Applications in Industry

Open-loop control systems are commonly used in applications such as conveyor belts, simple lighting systems, and basic heating elements where feedback is unnecessary for operation. Closed-loop control systems dominate in industries requiring precise regulation, including automotive cruise control, robotics, and HVAC systems, by continuously monitoring and adjusting performance through feedback sensors. The integration of closed-loop controls enhances process accuracy, stability, and efficiency in complex manufacturing and automation environments.

Choosing the Right Control System

Choosing the right control system hinges on the specific application requirements and environmental factors. Open-loop control systems are suitable for processes with predictable, stable conditions where feedback isn't essential, offering simplicity and lower cost. Closed-loop control systems provide higher accuracy and adaptability by continuously monitoring output and adjusting inputs, making them ideal for complex or variable environments.

Future Trends in Control System Technologies

Future trends in control system technologies emphasize the integration of artificial intelligence and machine learning to enhance both open-loop and closed-loop systems' adaptability and precision. Advanced sensors and IoT connectivity enable real-time data acquisition, improving closed-loop feedback mechanisms for predictive maintenance and autonomous decision-making. The shift toward hybrid control architectures leverages the simplicity of open-loop control with the robustness of closed-loop systems, optimizing performance in smart manufacturing and autonomous vehicles.

Open-loop vs Closed-loop control Infographic

electrown.com

electrown.com