Active clamp flyback converters improve efficiency and reduce voltage stress on power switches compared to traditional flyback designs by recycling leakage energy through an additional clamp circuit. Explore the rest of this article to discover how these benefits can enhance Your power supply applications.

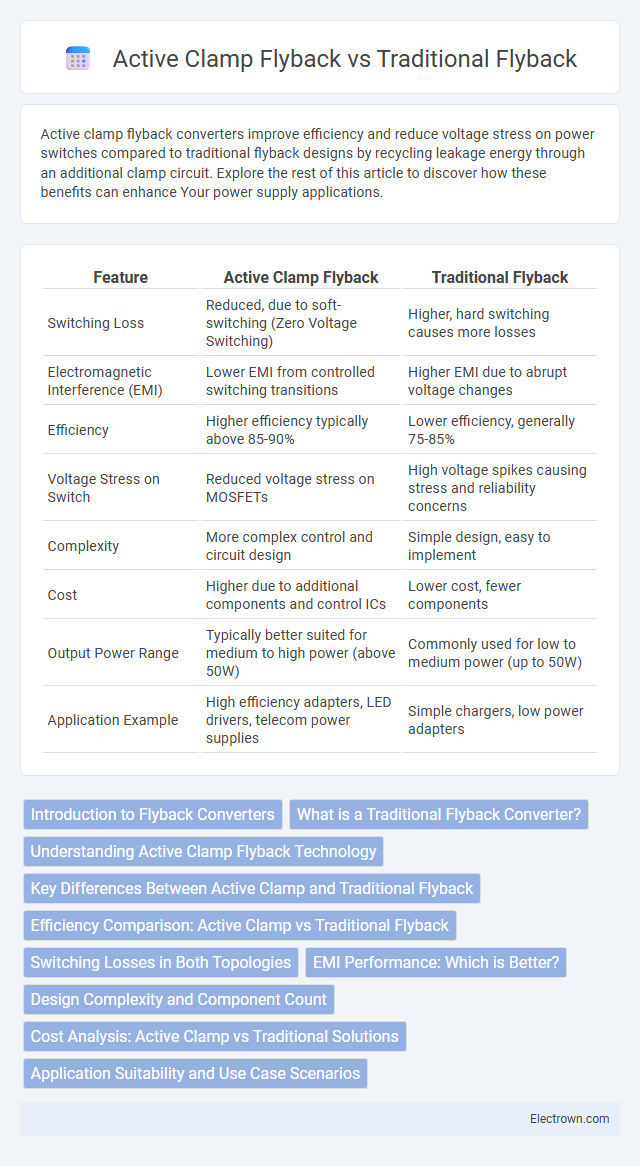

Table of Comparison

| Feature | Active Clamp Flyback | Traditional Flyback |

|---|---|---|

| Switching Loss | Reduced, due to soft-switching (Zero Voltage Switching) | Higher, hard switching causes more losses |

| Electromagnetic Interference (EMI) | Lower EMI from controlled switching transitions | Higher EMI due to abrupt voltage changes |

| Efficiency | Higher efficiency typically above 85-90% | Lower efficiency, generally 75-85% |

| Voltage Stress on Switch | Reduced voltage stress on MOSFETs | High voltage spikes causing stress and reliability concerns |

| Complexity | More complex control and circuit design | Simple design, easy to implement |

| Cost | Higher due to additional components and control ICs | Lower cost, fewer components |

| Output Power Range | Typically better suited for medium to high power (above 50W) | Commonly used for low to medium power (up to 50W) |

| Application Example | High efficiency adapters, LED drivers, telecom power supplies | Simple chargers, low power adapters |

Introduction to Flyback Converters

Flyback converters are widely used in isolated power supply applications due to their simplicity and cost-effectiveness. Traditional flyback converters operate by storing energy in the transformer's magnetic core during the switch-on period and releasing it to the output during the switch-off period, but suffer from high voltage stress and lower efficiency. Active clamp flyback converters enhance performance by reducing voltage stress on the switch through energy recycling, improving efficiency and reducing electromagnetic interference.

What is a Traditional Flyback Converter?

A traditional flyback converter is a type of switched-mode power supply that stores energy in a transformer during the switch-on period and releases it to the output during the switch-off period. It is widely used for low to medium power applications due to its simplicity, cost-effectiveness, and ability to provide galvanic isolation. Your choice of this converter impacts efficiency and electromagnetic interference compared to more advanced topologies like active clamp flyback.

Understanding Active Clamp Flyback Technology

Active Clamp Flyback technology enhances power efficiency and reduces voltage stress compared to traditional flyback converters by recycling the leakage energy through an additional clamp circuit. This method significantly improves voltage regulation and reduces electromagnetic interference, extending the lifespan of power components. Implementing this technology enables higher power density and better thermal management in power supply designs.

Key Differences Between Active Clamp and Traditional Flyback

Active clamp flyback converters enhance energy efficiency and reduce voltage stress on the primary switch compared to traditional flyback designs by recovering and recycling leakage inductance energy. Traditional flyback converters rely on a simple snubber circuit, leading to higher switching losses and increased electromagnetic interference (EMI). Your choice of an active clamp flyback offers improved thermal performance and enables higher switching frequencies, making it ideal for compact, high-density power supplies.

Efficiency Comparison: Active Clamp vs Traditional Flyback

Active clamp flyback converters significantly improve efficiency over traditional flyback designs by recovering energy stored in the transformer's leakage inductance, reducing switching losses and voltage stress on the main switches. Traditional flyback converters dissipate this leakage energy as heat, resulting in lower overall efficiency, especially at higher power levels. Your choice of active clamp topology can enhance power density and thermal performance, making it ideal for energy-sensitive applications.

Switching Losses in Both Topologies

Active clamp flyback converters significantly reduce switching losses by recycling the energy stored in the transformer's leakage inductance, enabling zero-voltage switching (ZVS) of the main switch and minimizing voltage stress. In contrast, traditional flyback converters experience higher switching losses due to hard switching, where the main switch turns on or off under high voltage and current conditions, leading to increased heat dissipation and reduced efficiency. The incorporation of the active clamp circuit not only recovers leakage energy but also ensures smoother voltage transitions, enhancing overall converter efficiency and thermal management.

EMI Performance: Which is Better?

Active clamp flyback converters offer superior EMI performance compared to traditional flyback designs due to their ability to reduce voltage spikes and ringing during switching transitions, which significantly lowers electromagnetic interference generation. The active clamp circuit recycles energy stored in the leakage inductance, minimizing stress on components and smoothing current waveforms, leading to cleaner switching signals and reduced EMI emissions. Your power supply designs benefit from improved compliance with EMI standards and enhanced overall system reliability by choosing active clamp flyback topology.

Design Complexity and Component Count

Active clamp flyback converters exhibit higher design complexity compared to traditional flyback due to the inclusion of additional components such as an active clamp switch, capacitor, and control circuitry. This results in increased component count but enables improved efficiency and reduced voltage stress. Your design choices must balance the complexity with the benefits offered by the active clamp topology.

Cost Analysis: Active Clamp vs Traditional Solutions

Active clamp flyback converters typically incur higher initial costs due to additional components like clamp switches and capacitors, which increase fabrication expenses compared to traditional flyback designs. However, your energy savings from improved efficiency and reduced stress on the transformer and switching devices can offset these upfront costs over time, leading to lower total cost of ownership. Manufacturers evaluating cost analysis often consider reliability gains and reduced electromagnetic interference benefits that active clamp solutions provide, despite the complexity and cost premiums.

Application Suitability and Use Case Scenarios

Active clamp flyback converters excel in high-efficiency, high-power applications such as server power supplies or telecom systems, where reduced switching losses and enhanced voltage stress management are critical. Traditional flyback converters remain suitable for low to medium power applications like battery chargers and standby power supplies due to their simplicity and cost-effectiveness. Your choice depends on the specific power requirements, efficiency targets, and complexity constraints of the intended application.

active clamp flyback vs traditional flyback Infographic

electrown.com

electrown.com