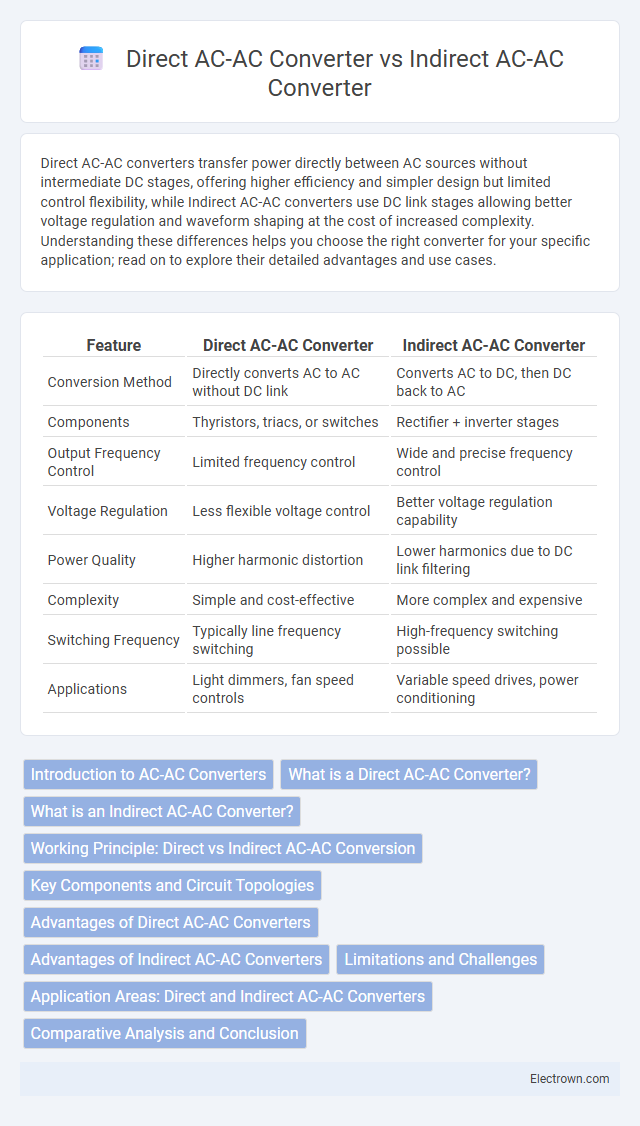

Direct AC-AC converters transfer power directly between AC sources without intermediate DC stages, offering higher efficiency and simpler design but limited control flexibility, while Indirect AC-AC converters use DC link stages allowing better voltage regulation and waveform shaping at the cost of increased complexity. Understanding these differences helps you choose the right converter for your specific application; read on to explore their detailed advantages and use cases.

Table of Comparison

| Feature | Direct AC-AC Converter | Indirect AC-AC Converter |

|---|---|---|

| Conversion Method | Directly converts AC to AC without DC link | Converts AC to DC, then DC back to AC |

| Components | Thyristors, triacs, or switches | Rectifier + inverter stages |

| Output Frequency Control | Limited frequency control | Wide and precise frequency control |

| Voltage Regulation | Less flexible voltage control | Better voltage regulation capability |

| Power Quality | Higher harmonic distortion | Lower harmonics due to DC link filtering |

| Complexity | Simple and cost-effective | More complex and expensive |

| Switching Frequency | Typically line frequency switching | High-frequency switching possible |

| Applications | Light dimmers, fan speed controls | Variable speed drives, power conditioning |

Introduction to AC-AC Converters

AC-AC converters convert alternating current (AC) from one voltage or frequency to another without the intermediate DC stage. Direct AC-AC converters, also known as cycloconverters or matrix converters, transform input AC power directly to output AC power, enabling frequency changes with minimal harmonic distortion. Indirect AC-AC converters involve two stages: rectification of AC to DC followed by inversion back to AC, offering enhanced control over output voltage and frequency but with increased complexity and power losses.

What is a Direct AC-AC Converter?

A Direct AC-AC converter is an electrical device that converts an alternating current (AC) input voltage directly into a different AC output voltage without an intermediate DC link. It typically uses semiconductor switches such as thyristors or triacs to control and adjust the output frequency and amplitude in real-time. This conversion method offers higher efficiency and reduced size compared to indirect AC-AC converters, making it suitable for applications like voltage regulation and speed control in AC drives.

What is an Indirect AC-AC Converter?

An Indirect AC-AC converter transforms input AC voltage to a controlled AC output through an intermediate DC stage, typically using a rectifier followed by an inverter. This converter provides better output voltage and frequency control compared to direct AC-AC converters, enabling efficient speed regulation in variable frequency drives (VFDs). Common applications include adjustable-speed motor drives and power supplies requiring precise voltage and frequency adjustments.

Working Principle: Direct vs Indirect AC-AC Conversion

Direct AC-AC converters transform input alternating current directly into output alternating current of desired voltage and frequency using semiconductor switches without an intermediate DC stage, enabling efficient and compact designs. Indirect AC-AC converters convert AC to DC through a rectifier stage, then invert the DC back to AC with controlled frequency and voltage, offering greater flexibility in output waveform shaping and voltage regulation. Your choice depends on application needs for simplicity and efficiency in direct converters or enhanced control and customization in indirect converters.

Key Components and Circuit Topologies

Direct AC-AC converters utilize semiconductor switches such as TRIACs, thyristors, or triodes for direct voltage transformation without intermediate DC stages, typically implementing single-phase or three-phase cycloconverter topologies. Indirect AC-AC converters employ a rectifier stage followed by an inverter, incorporating components like diodes, IGBTs, or MOSFETs, with common configurations including matrix converters and AC-DC-AC two-stage converters that allow enhanced control over voltage and frequency. Key distinctions lie in circuit topology complexity and component count, where direct converters offer simpler, compact designs while indirect converters provide superior output waveform quality and controllability.

Advantages of Direct AC-AC Converters

Direct AC-AC converters offer higher efficiency and reduced harmonic distortion by eliminating the intermediate DC stage, enabling faster response times and simpler control schemes. These converters afford compact design and lower cost due to fewer power electronic components and decreased energy losses. Their ability to directly modulate voltage and frequency supports improved performance in applications such as variable-speed drives and power conversion systems.

Advantages of Indirect AC-AC Converters

Indirect AC-AC converters offer superior output voltage and frequency control by using an intermediate DC link, allowing for better power quality and reduced harmonic distortion compared to direct AC-AC converters. These converters enable bidirectional power flow and smoother transition during speed or torque control in motor drives, enhancing overall system efficiency and performance. The presence of two-stage conversion in indirect AC-AC converters also facilitates easier fault management and improved reliability in industrial applications.

Limitations and Challenges

Direct AC-AC converters face limitations such as limited output voltage control range and higher harmonic distortion due to the absence of intermediate DC link filtering. Indirect AC-AC converters, while offering better voltage regulation and reduced harmonics through DC link smoothing, encounter challenges like increased circuit complexity and higher cost resulting from additional power electronic components. Both converter types struggle with efficiency trade-offs and electromagnetic interference issues that impact overall system performance.

Application Areas: Direct and Indirect AC-AC Converters

Direct AC-AC converters excel in applications requiring simple, efficient voltage control, such as in lighting dimmers, speed control of small motors, and domestic appliances. Indirect AC-AC converters are preferred in industrial settings that demand precise frequency and voltage regulation, including variable frequency drives for large motors, renewable energy systems, and traction drives. Your choice depends on the complexity and performance needs, with direct converters suited for straightforward applications and indirect converters for advanced power control.

Comparative Analysis and Conclusion

Direct AC-AC converters provide a simplified power conversion process by directly modifying the input AC waveform, leading to higher efficiency and reduced component count compared to indirect AC-AC converters, which first convert AC to DC and then back to AC. Indirect converters offer greater flexibility in output control, such as adjustable frequency and voltage, benefiting applications requiring precise power modulation. The choice between direct and indirect AC-AC converters depends on system requirements for efficiency, control complexity, and application-specific performance criteria.

Direct AC-AC converter vs Indirect AC-AC converter Infographic

electrown.com

electrown.com