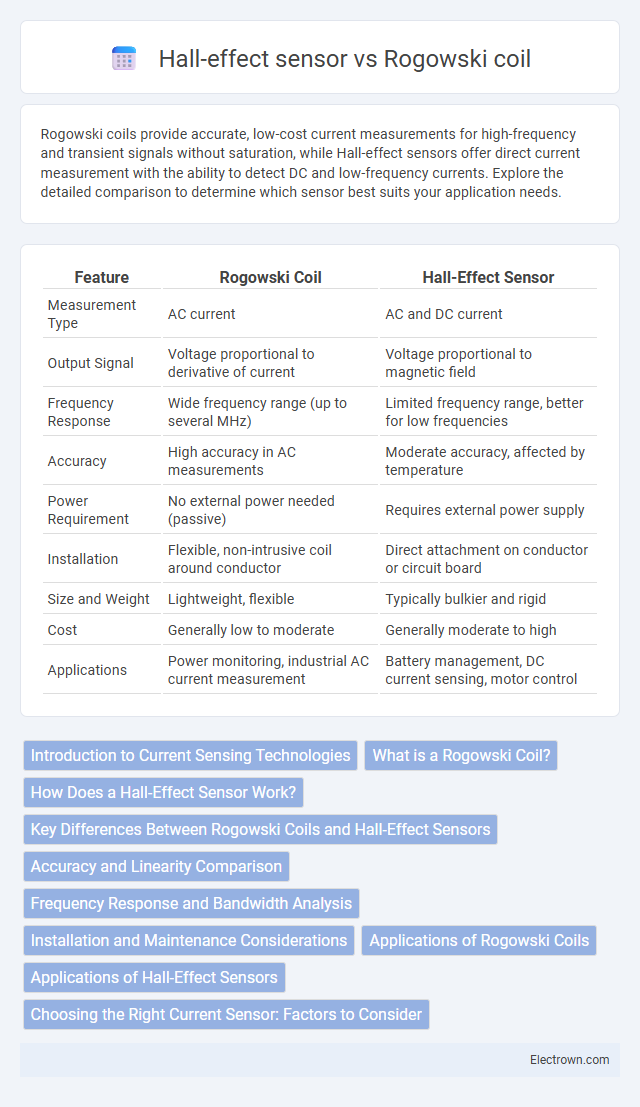

Rogowski coils provide accurate, low-cost current measurements for high-frequency and transient signals without saturation, while Hall-effect sensors offer direct current measurement with the ability to detect DC and low-frequency currents. Explore the detailed comparison to determine which sensor best suits your application needs.

Table of Comparison

| Feature | Rogowski Coil | Hall-Effect Sensor |

|---|---|---|

| Measurement Type | AC current | AC and DC current |

| Output Signal | Voltage proportional to derivative of current | Voltage proportional to magnetic field |

| Frequency Response | Wide frequency range (up to several MHz) | Limited frequency range, better for low frequencies |

| Accuracy | High accuracy in AC measurements | Moderate accuracy, affected by temperature |

| Power Requirement | No external power needed (passive) | Requires external power supply |

| Installation | Flexible, non-intrusive coil around conductor | Direct attachment on conductor or circuit board |

| Size and Weight | Lightweight, flexible | Typically bulkier and rigid |

| Cost | Generally low to moderate | Generally moderate to high |

| Applications | Power monitoring, industrial AC current measurement | Battery management, DC current sensing, motor control |

Introduction to Current Sensing Technologies

Rogowski coils and Hall-effect sensors are essential current sensing technologies used for precise electrical measurements in power systems and industrial applications. Rogowski coils offer high-frequency response and non-intrusive AC current measurement thanks to their air-cored, flexible design, while Hall-effect sensors provide direct measurement of both AC and DC currents through magnetic field detection using semiconductor components. Your choice between these sensors depends on factors such as current type, frequency range, installation constraints, and accuracy requirements.

What is a Rogowski Coil?

A Rogowski coil is a toroidal electrical device used to measure alternating current (AC) by detecting the magnetic field produced by the conductor. Unlike Hall-effect sensors, it provides a non-intrusive, lightweight, and flexible solution with high linearity and wide frequency response, ideal for transient and high-speed current measurement. You can benefit from its immunity to saturation and minimal insertion loss when monitoring large or complex current waveforms.

How Does a Hall-Effect Sensor Work?

A Hall-effect sensor operates by detecting the magnetic field generated by current flow through a conductor; when current passes, it produces a magnetic field perpendicular to the current direction. The sensor contains a thin strip of semiconductor material that generates a voltage (Hall voltage) proportional to the magnetic field strength, allowing precise current measurement without direct electrical contact. Your choice between a Rogowski coil and a Hall-effect sensor depends on factors like accuracy, size, and frequency response, with Hall-effect sensors excelling in low-frequency current sensing.

Key Differences Between Rogowski Coils and Hall-Effect Sensors

Rogowski coils measure alternating current by detecting the rate of change of magnetic flux without saturation, providing high linearity and wide frequency response ideal for transient and high-frequency current measurements. Hall-effect sensors directly measure magnetic fields generated by current flow, offering the ability to sense both AC and DC currents with static and dynamic accuracy but may suffer from magnetic saturation and temperature sensitivity. Your choice depends on application requirements such as frequency range, current type, installation space, and sensitivity to environmental factors.

Accuracy and Linearity Comparison

Rogowski coils offer excellent linearity over a wide current range, making them highly accurate for measuring high-frequency and transient currents without saturation effects. Hall-effect sensors provide good accuracy at low to moderate currents but may exhibit non-linearity and drift at extreme current levels or temperatures. Your choice depends on whether precision over a broad dynamic range or stable performance at lower currents is more critical for your application.

Frequency Response and Bandwidth Analysis

Rogowski coils exhibit a wide frequency response, typically ranging from a few hertz up to several hundred kilohertz, making them ideal for accurate measurement of transient currents and high-frequency signals. Hall-effect sensors, while effective for DC and low-frequency AC current detection, generally have a more limited bandwidth, often restricted to tens of kilohertz, which can affect their performance in high-speed applications. Your choice between these sensors should consider the specific frequency range and bandwidth requirements of the measurement environment to ensure precise and reliable current sensing.

Installation and Maintenance Considerations

Rogowski coils offer flexible, clamp-on installation without the need to disconnect the conductor, minimizing downtime and simplifying maintenance procedures. Hall-effect sensors require direct conductor contact or insertion through core apertures, which can complicate installation and increase the likelihood of maintenance errors. The non-intrusive design of Rogowski coils reduces wear and exposure to environmental factors, enhancing long-term reliability compared to Hall-effect sensors.

Applications of Rogowski Coils

Rogowski coils are widely used for measuring alternating current (AC) in power systems, providing precise, non-intrusive current sensing for protection relays and power quality monitoring. Their flexible, air-core design allows easy installation around busbars and cables in industrial environments, making them ideal for transient current measurement and fault detection. You benefit from their wide frequency range and linear output in applications such as smart grid monitoring, power transformers, and transient event analysis.

Applications of Hall-Effect Sensors

Hall-effect sensors are widely used for precise current measurement in applications such as motor control, battery management systems, and overcurrent protection due to their robustness and ability to measure both AC and DC currents. Unlike Rogowski coils, which are limited to AC measurements, Hall-effect sensors provide reliable real-time data for electronic devices and industrial automation. Your systems can benefit from their compact size and the ability to detect magnetic fields without direct electrical contact.

Choosing the Right Current Sensor: Factors to Consider

Choosing between a Rogowski coil and a Hall-effect sensor depends heavily on factors such as current range, frequency response, and installation environment. Rogowski coils excel in measuring high-frequency, AC currents with minimal insertion loss and no saturation, making them ideal for transient or pulsed current applications. Hall-effect sensors provide versatile DC and AC current detection with direct magnetic field measurement, compact size, and output voltage proportional to current, which suits low to medium current ranges and environments requiring galvanic isolation.

Rogowski coil vs Hall-effect sensor Infographic

electrown.com

electrown.com