Synchronous flyback converters improve efficiency by using a MOSFET instead of a diode for synchronous rectification, reducing voltage drop and power loss compared to conventional flyback designs. Discover how these differences impact your power supply's performance and applications by reading the rest of the article.

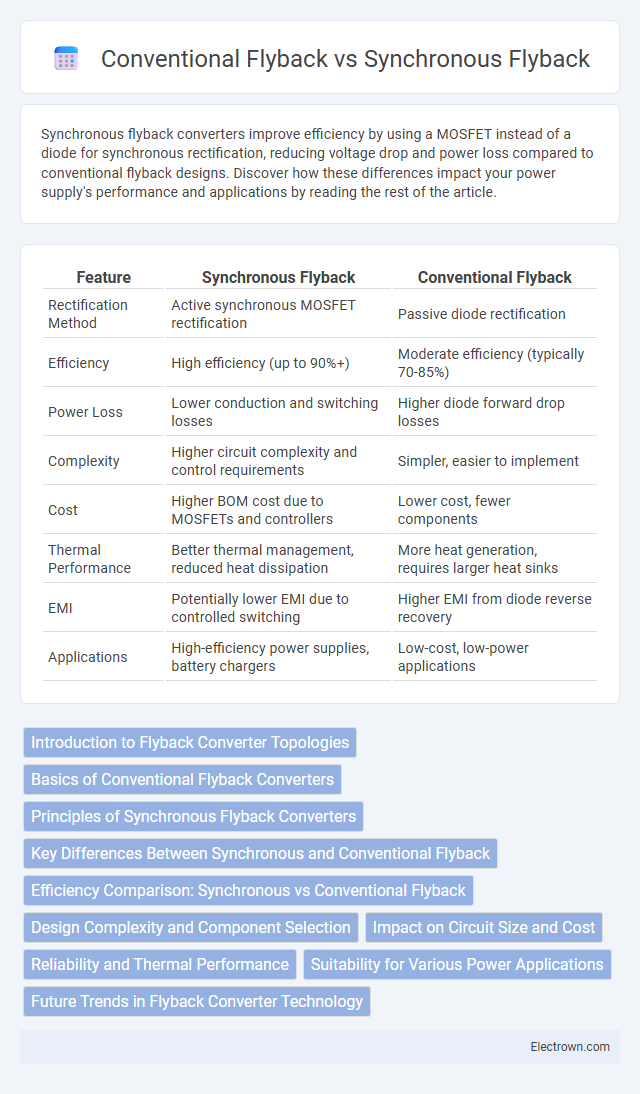

Table of Comparison

| Feature | Synchronous Flyback | Conventional Flyback |

|---|---|---|

| Rectification Method | Active synchronous MOSFET rectification | Passive diode rectification |

| Efficiency | High efficiency (up to 90%+) | Moderate efficiency (typically 70-85%) |

| Power Loss | Lower conduction and switching losses | Higher diode forward drop losses |

| Complexity | Higher circuit complexity and control requirements | Simpler, easier to implement |

| Cost | Higher BOM cost due to MOSFETs and controllers | Lower cost, fewer components |

| Thermal Performance | Better thermal management, reduced heat dissipation | More heat generation, requires larger heat sinks |

| EMI | Potentially lower EMI due to controlled switching | Higher EMI from diode reverse recovery |

| Applications | High-efficiency power supplies, battery chargers | Low-cost, low-power applications |

Introduction to Flyback Converter Topologies

Synchronous flyback converters utilize integrated synchronous rectifiers instead of traditional diodes found in conventional flyback topologies, enhancing efficiency by reducing conduction losses and improving thermal performance. Conventional flyback converters rely on diode rectification for output current, which introduces higher voltage drops and limits efficiency, especially at low output voltages. Your choice between synchronous and conventional flyback topologies depends on application requirements such as power output, efficiency targets, and design complexity.

Basics of Conventional Flyback Converters

Conventional flyback converters use a transformer to store energy during the switch-on period and release it to the output during the switch-off period, providing electrical isolation and voltage step-up or step-down capabilities. These converters rely on a single power switch and a diode for rectification, which can lead to power losses due to diode forward voltage drops. Your power supply design can benefit from understanding these basics to improve efficiency and reliability in low to medium power applications.

Principles of Synchronous Flyback Converters

Synchronous flyback converters improve energy efficiency by replacing the traditional diode with a controlled MOSFET, minimizing conduction losses during the freewheeling phase. This design enables precise control of the synchronous rectifier's timing, enhancing power conversion efficiency compared to conventional flyback converters, which rely on diodes with higher forward voltage drops. You benefit from reduced heat dissipation and increased overall efficiency, making synchronous flyback topologies ideal for low to medium power applications.

Key Differences Between Synchronous and Conventional Flyback

Synchronous flyback converters use active MOSFET switches to replace diodes, significantly improving efficiency by reducing conduction losses compared to conventional flyback converters that rely on diode rectification. The synchronous design enables better control of switching timing and reduced voltage drops, enhancing power conversion performance in low-voltage, high-current applications. Conventional flyback converters typically have simpler designs and lower component costs but suffer from higher power dissipation and lower overall efficiency due to diode forward voltage drops.

Efficiency Comparison: Synchronous vs Conventional Flyback

Synchronous flyback converters offer significantly higher efficiency compared to conventional flyback designs due to reduced conduction losses achieved by replacing the traditional diode with a low-resistance MOSFET. This improvement typically results in efficiency gains of 5-10%, especially under light to medium load conditions, directly benefiting your power supply's overall performance and thermal management. By minimizing voltage drops and switch losses, synchronous flyback topology extends battery life and enhances energy savings in various applications.

Design Complexity and Component Selection

Synchronous flyback converters reduce conduction losses by replacing the output diode with a synchronous MOSFET, which demands more complex control circuitry and precise timing for efficient switching. Conventional flyback designs utilize simpler components like diodes and traditional transformers, resulting in straightforward design and easier component selection but higher power dissipation. Choosing between synchronous and conventional flyback involves balancing design complexity against efficiency requirements and component cost constraints.

Impact on Circuit Size and Cost

Synchronous flyback converters reduce overall circuit size by integrating low-resistance MOSFETs as synchronous rectifiers, eliminating bulky diodes and minimizing heat sink requirements. This integration improves efficiency and reduces power losses, leading to lower thermal management costs despite a slightly higher initial component expense. Conventional flyback designs, relying on discrete diodes, tend to have larger PCB footprints and increased thermal dissipation, resulting in higher long-term costs due to less efficient heat management.

Reliability and Thermal Performance

Synchronous flyback converters enhance reliability by reducing voltage stress and improving efficiency, leading to lower thermal dissipation compared to conventional flyback designs. Your system benefits from reduced heat generation, which extends component lifespan and minimizes the risk of thermal-related failures. Improved thermal performance supports higher power density and stable operation under varying load conditions.

Suitability for Various Power Applications

Synchronous flyback converters offer improved efficiency and better thermal performance, making them ideal for high-power, high-frequency applications such as telecommunications and industrial power supplies. Conventional flyback converters remain suitable for low-to-medium power applications where simplicity and cost-effectiveness are prioritized, including consumer electronics and small adapters. Your choice depends on the specific power requirements and efficiency targets of your design project.

Future Trends in Flyback Converter Technology

Synchronous flyback converters are rapidly gaining traction over conventional flyback designs due to enhanced efficiency and reduced power losses, driven by advances in synchronous rectification technology and wide-bandgap semiconductor materials like GaN and SiC. Emerging trends emphasize integrated control ICs with digital optimization and adaptive switching techniques to further improve performance in low-voltage, high-frequency applications. The future of flyback converters strongly aligns with smart power management solutions, enabling higher power density and compliance with stringent energy efficiency regulations in modern power supplies.

synchronous flyback vs conventional flyback Infographic

electrown.com

electrown.com