Synchronous buck converters use a pair of MOSFETs for both high and low side switching, improving efficiency by reducing conduction losses, while asynchronous buck converters rely on a diode for the low side, resulting in simpler design but lower efficiency. Understanding these differences can help you choose the best converter for your power management needs; read on to explore detailed comparisons and applications.

Table of Comparison

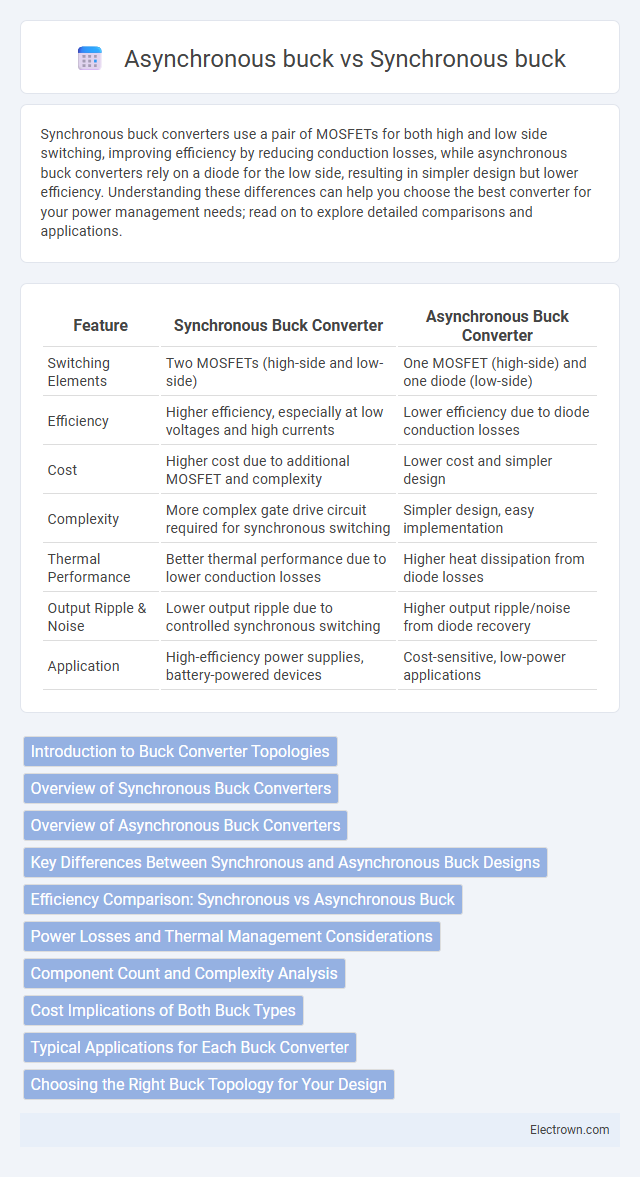

| Feature | Synchronous Buck Converter | Asynchronous Buck Converter |

|---|---|---|

| Switching Elements | Two MOSFETs (high-side and low-side) | One MOSFET (high-side) and one diode (low-side) |

| Efficiency | Higher efficiency, especially at low voltages and high currents | Lower efficiency due to diode conduction losses |

| Cost | Higher cost due to additional MOSFET and complexity | Lower cost and simpler design |

| Complexity | More complex gate drive circuit required for synchronous switching | Simpler design, easy implementation |

| Thermal Performance | Better thermal performance due to lower conduction losses | Higher heat dissipation from diode losses |

| Output Ripple & Noise | Lower output ripple due to controlled synchronous switching | Higher output ripple/noise from diode recovery |

| Application | High-efficiency power supplies, battery-powered devices | Cost-sensitive, low-power applications |

Introduction to Buck Converter Topologies

Synchronous buck converters use two controlled switches, typically MOSFETs, to improve efficiency by reducing power loss during switching, while asynchronous buck converters use a diode as the second component, resulting in higher conduction losses. The synchronous topology is preferred for low-voltage, high-current applications due to its ability to achieve better efficiency and thermal performance. Understanding the differences between these buck converter topologies helps optimize Your power supply design for specific load and efficiency requirements.

Overview of Synchronous Buck Converters

Synchronous buck converters use MOSFETs for both the high-side and low-side switches, significantly improving efficiency by reducing power losses compared to diode-based asynchronous designs. Your power supply system benefits from higher efficiency, lower heat dissipation, and better performance in low voltage, high current applications. These converters are widely preferred in modern electronics due to their ability to provide stable, regulated output with minimal energy waste.

Overview of Asynchronous Buck Converters

Asynchronous buck converters use a single high-side MOSFET switch and a diode to control voltage step-down, enabling simpler design with lower cost and reduced electromagnetic interference. They are ideal for applications where efficiency under light load conditions is less critical, as the diode introduces higher conduction losses compared to synchronous designs. Your choice depends on balancing efficiency, complexity, and cost requirements for your power management solution.

Key Differences Between Synchronous and Asynchronous Buck Designs

Synchronous buck converters use MOSFETs for both high-side and low-side switches, enhancing efficiency and reducing conduction losses compared to asynchronous buck designs that rely on a diode for the low-side switch. The synchronous design offers better control and lower power dissipation, which results in higher efficiency especially at low output voltages and high currents. When choosing a power conversion solution for your application, consider that synchronous buck converters provide improved thermal performance and energy savings over asynchronous buck converters.

Efficiency Comparison: Synchronous vs Asynchronous Buck

Synchronous buck converters exhibit higher efficiency than asynchronous buck converters due to reduced conduction losses, as they replace the diode with a low-resistance MOSFET that minimizes voltage drop during switching. Asynchronous designs rely on a diode which incurs higher forward voltage and power dissipation, especially at higher load currents, leading to lower overall efficiency. Efficiency gains in synchronous buck converters typically range from 3% to 8% depending on load conditions and switching frequency, making them ideal for power-sensitive applications.

Power Losses and Thermal Management Considerations

Synchronous buck converters exhibit lower power losses compared to asynchronous buck converters due to the use of MOSFETs instead of diodes, reducing conduction losses and improving efficiency. This efficient power conversion results in reduced heat generation, easing thermal management requirements and enabling smaller heat sinks or cooling solutions. However, synchronous designs can introduce complexity in gate drive control, which must be managed to prevent additional switching losses and thermal stress.

Component Count and Complexity Analysis

Synchronous buck converters typically feature a higher component count due to the inclusion of an additional MOSFET replacing the diode, which increases circuit complexity but enhances efficiency. Asynchronous buck converters use fewer components, primarily a single MOSFET and a diode, resulting in simpler designs with potentially higher conduction losses. Your choice between synchronous and asynchronous buck converters will depend on the trade-off between circuit complexity and efficiency requirements.

Cost Implications of Both Buck Types

Synchronous buck converters generally have higher initial costs due to their use of MOSFETs for both high-side and low-side switches, which improve efficiency but increase component expenses. Asynchronous buck converters are typically less expensive because they use a diode for the low-side switch, reducing component cost but sacrificing efficiency and generating more heat. The trade-off between these buck types centers on balancing upfront cost against long-term energy savings and thermal management requirements.

Typical Applications for Each Buck Converter

Synchronous buck converters are commonly used in high-efficiency applications such as CPU power supplies, graphics cards, and telecommunications equipment due to their low conduction losses and improved thermal performance. Asynchronous buck converters are preferred in simpler, cost-sensitive applications like battery-powered devices, LED drivers, and low-power industrial systems where lower complexity and cost outweigh efficiency gains. The choice between synchronous and asynchronous topologies depends on power requirements, efficiency targets, and system cost constraints.

Choosing the Right Buck Topology for Your Design

Selecting the right buck topology is crucial for optimizing power efficiency and thermal performance in your design. Synchronous buck converters use MOSFETs for both the high-side and low-side switches, offering higher efficiency at low voltages and loads due to reduced conduction losses. Asynchronous buck converters replace the low-side MOSFET with a diode, simplifying the circuit and lowering cost, but at the expense of efficiency and increased heat generated by the diode's voltage drop.

Synchronous buck vs Asynchronous buck Infographic

electrown.com

electrown.com