Hysteresis current control provides fast and precise current regulation by keeping the current within a predefined band, while PWM current control offers smoother output and improved efficiency through fixed-frequency pulse-width modulation. Explore the article to understand which method best suits Your power electronics application.

Table of Comparison

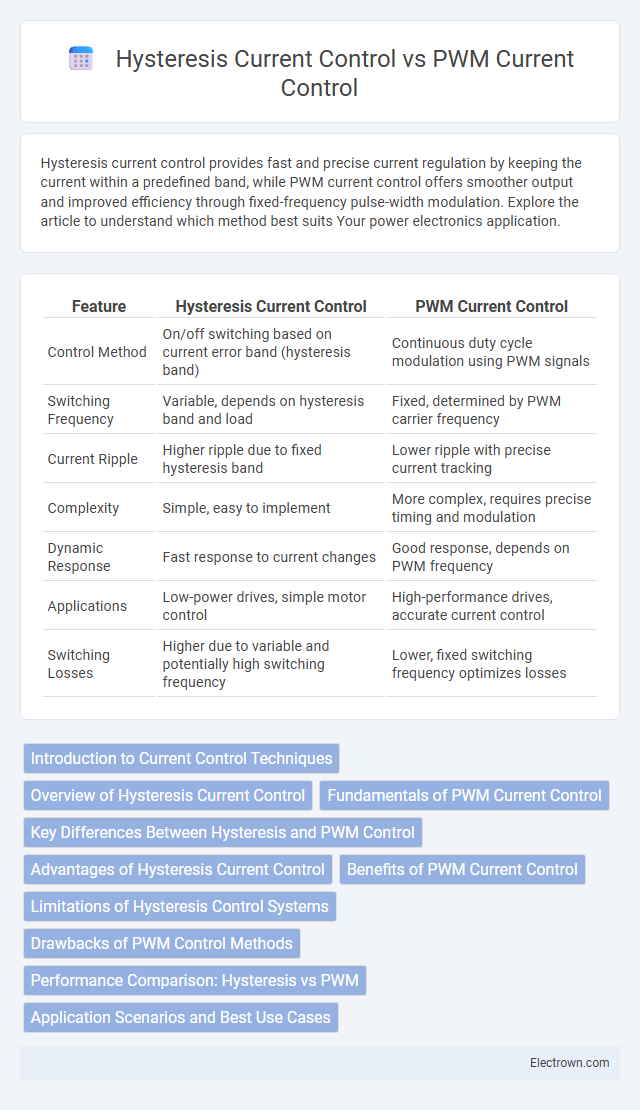

| Feature | Hysteresis Current Control | PWM Current Control |

|---|---|---|

| Control Method | On/off switching based on current error band (hysteresis band) | Continuous duty cycle modulation using PWM signals |

| Switching Frequency | Variable, depends on hysteresis band and load | Fixed, determined by PWM carrier frequency |

| Current Ripple | Higher ripple due to fixed hysteresis band | Lower ripple with precise current tracking |

| Complexity | Simple, easy to implement | More complex, requires precise timing and modulation |

| Dynamic Response | Fast response to current changes | Good response, depends on PWM frequency |

| Applications | Low-power drives, simple motor control | High-performance drives, accurate current control |

| Switching Losses | Higher due to variable and potentially high switching frequency | Lower, fixed switching frequency optimizes losses |

Introduction to Current Control Techniques

Hysteresis current control offers precise, real-time current tracking by instantly adjusting inverter switching to maintain the current within a defined hysteresis band, resulting in fast dynamic response and reduced control complexity. PWM current control, on the other hand, relies on fixed switching frequency with modulated pulse widths to regulate current, providing predictable harmonic profiles and improved efficiency for steady-state operation. Your choice between these methods influences system performance, switching losses, and electromagnetic interference levels in motor drives and power converters.

Overview of Hysteresis Current Control

Hysteresis current control regulates motor current by maintaining it within a predefined hysteresis band, providing fast dynamic response and precise current tracking. This method detects current deviations and switches the inverter states to keep the current oscillating around the reference, ensuring low current distortion. Your motor drive benefits from reduced electromagnetic interference and straightforward implementation compared to PWM current control.

Fundamentals of PWM Current Control

PWM current control operates by switching the power devices at a fixed frequency and adjusting the duty cycle to regulate the current within a desired reference value. This method enables precise control of the current waveform, reduces harmonic distortion, and improves efficiency compared to hysteresis current control, which varies switching frequency. PWM current control is fundamental in modern power electronics for maintaining stable current in applications like motor drives and inverters.

Key Differences Between Hysteresis and PWM Control

Hysteresis current control maintains the motor current within a fixed band by switching the inverter states instantly, resulting in variable switching frequency and fast dynamic response. PWM current control uses a fixed switching frequency with modulated pulse widths to regulate the current, providing predictable harmonic performance and reduced electromagnetic interference. Your choice depends on whether you prioritize precise current control with variable switching or consistent frequency with lower noise emissions.

Advantages of Hysteresis Current Control

Hysteresis current control offers superior dynamic response and precise current regulation due to its ability to maintain the current within a predefined band without delay. This method reduces switching losses and simplifies the control algorithm compared to PWM current control, enhancing efficiency and reliability in high-performance motor drives. Your system benefits from low computational requirements and inherent robustness to parameter variations, making hysteresis control ideal for applications demanding fast and accurate current tracking.

Benefits of PWM Current Control

PWM current control offers precise regulation of motor current by modulating pulse width, resulting in higher efficiency and reduced power loss compared to hysteresis current control. This method enables smoother motor operation, minimizes torque ripple, and improves overall performance in applications requiring fine current adjustments. Your system benefits from enhanced thermal management and reduced electromagnetic interference due to the fixed switching frequency characteristic of PWM current control.

Limitations of Hysteresis Control Systems

Hysteresis current control systems face limitations such as variable switching frequency, which leads to increased electromagnetic interference (EMI) and challenges in filter design. The inability to maintain a fixed switching frequency can cause unpredictable harmonic distortion, impacting system efficiency and reliability. Additionally, the controller complexity increases with the need to manage rapid switching transitions, limiting scalability in high-power applications.

Drawbacks of PWM Control Methods

PWM current control methods often suffer from fixed switching frequencies that can cause electromagnetic interference (EMI) and reduce system efficiency under varying load conditions. These methods may also introduce switching losses and heat dissipation challenges, limiting their performance in high-frequency applications. Furthermore, the inability to dynamically adjust switching behavior can result in suboptimal current regulation compared to hysteresis current control techniques.

Performance Comparison: Hysteresis vs PWM

Hysteresis current control offers fast dynamic response and inherent overcurrent protection by allowing current to oscillate within a defined band, making it ideal for applications requiring rapid load changes. PWM current control provides precise and stable current regulation with lower switching losses and better harmonic performance, suitable for high-efficiency and noise-sensitive systems. The choice between hysteresis and PWM control depends on the trade-off between switching frequency variability and steady-state accuracy in power converters.

Application Scenarios and Best Use Cases

Hysteresis current control excels in applications requiring fast dynamic response and precise current regulation, such as motor drives in servo systems and traction control, due to its inherent simplicity and robustness. PWM current control is best suited for scenarios demanding high switching frequency and low harmonic distortion, like industrial inverters and renewable energy converters, enabling smoother operation and better efficiency. Your choice between these methods depends on specific application needs such as response speed, switching frequency, and thermal management constraints.

hysteresis current control vs pwm current control Infographic

electrown.com

electrown.com