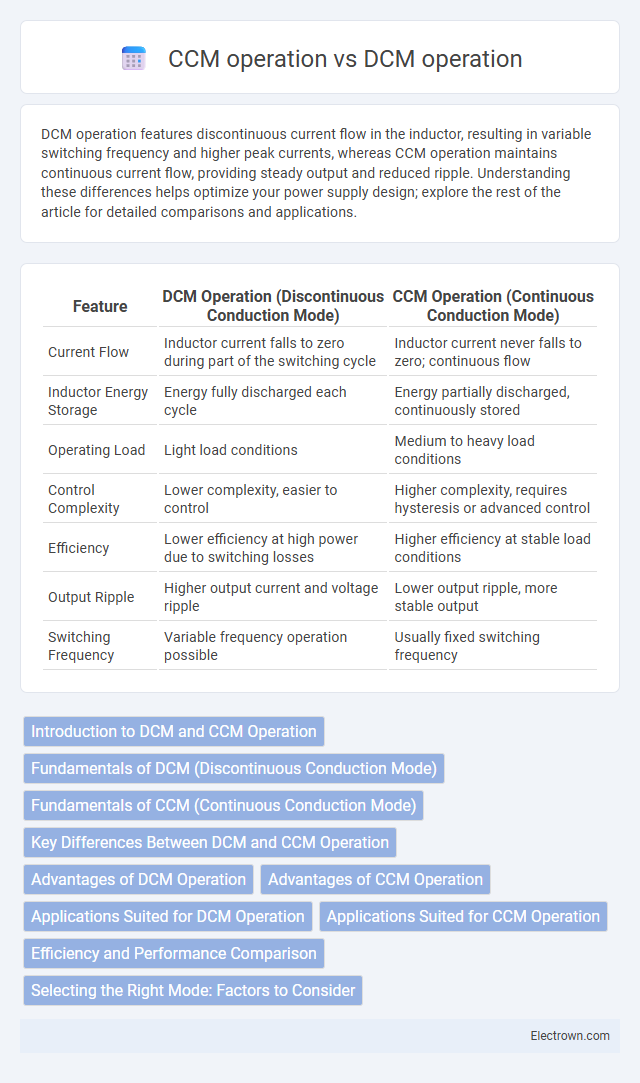

DCM operation features discontinuous current flow in the inductor, resulting in variable switching frequency and higher peak currents, whereas CCM operation maintains continuous current flow, providing steady output and reduced ripple. Understanding these differences helps optimize your power supply design; explore the rest of the article for detailed comparisons and applications.

Table of Comparison

| Feature | DCM Operation (Discontinuous Conduction Mode) | CCM Operation (Continuous Conduction Mode) |

|---|---|---|

| Current Flow | Inductor current falls to zero during part of the switching cycle | Inductor current never falls to zero; continuous flow |

| Inductor Energy Storage | Energy fully discharged each cycle | Energy partially discharged, continuously stored |

| Operating Load | Light load conditions | Medium to heavy load conditions |

| Control Complexity | Lower complexity, easier to control | Higher complexity, requires hysteresis or advanced control |

| Efficiency | Lower efficiency at high power due to switching losses | Higher efficiency at stable load conditions |

| Output Ripple | Higher output current and voltage ripple | Lower output ripple, more stable output |

| Switching Frequency | Variable frequency operation possible | Usually fixed switching frequency |

Introduction to DCM and CCM Operation

Discontinuous Conduction Mode (DCM) occurs when the inductor current falls to zero during part of the switching cycle, typically in low load conditions, resulting in variable frequency and improved efficiency at light loads. Continuous Conduction Mode (CCM) maintains current flow through the inductor throughout the entire switching cycle, providing lower ripple and more stable operation under higher load currents. Understanding the differences between DCM and CCM is essential for optimizing power converter designs for efficiency, response time, and electromagnetic interference (EMI) characteristics.

Fundamentals of DCM (Discontinuous Conduction Mode)

Discontinuous Conduction Mode (DCM) occurs when the inductor current in a power converter falls to zero during part of the switching cycle, leading to non-continuous energy flow. This operation mode contrasts with Continuous Conduction Mode (CCM), where the inductor current remains above zero throughout the cycle, providing smoother power delivery and lower current ripple. DCM is characterized by simpler control schemes and reduced switching losses but typically results in higher current stress and increased output voltage ripple compared to CCM.

Fundamentals of CCM (Continuous Conduction Mode)

Continuous Conduction Mode (CCM) ensures the inductor current never falls to zero during each switching cycle, enabling smoother current flow and reduced electromagnetic interference. In CCM, the inductor current ripple is smaller, which enhances efficiency and allows better control of output voltage and current in power converters. Understanding these fundamentals helps you design more stable and efficient DC-DC converters for applications requiring consistent power delivery.

Key Differences Between DCM and CCM Operation

DCM operation occurs when the inductor current falls to zero during each switching cycle, leading to discontinuous energy flow, while CCM operation maintains a continuous current through the inductor without reaching zero. DCM typically results in higher peak currents and increased stress on components, whereas CCM offers lower peak current and reduced electromagnetic interference (EMI). Your choice between DCM and CCM affects efficiency, transient response, and overall converter performance based on load conditions.

Advantages of DCM Operation

Discontinuous Conduction Mode (DCM) operation in power converters offers advantages such as reduced switching losses and simpler control schemes compared to Continuous Conduction Mode (CCM). DCM typically results in lower electromagnetic interference (EMI) due to zero current at switch turn-on, improving overall system reliability. It also enables faster dynamic response and easier implementation of current-mode control, benefiting applications requiring rapid load changes.

Advantages of CCM Operation

Continuous Conduction Mode (CCM) operation offers advantages such as reduced current ripple and lower electromagnetic interference (EMI), leading to improved efficiency and better thermal management in power converters. CCM maintains a steady inductor current, which enhances voltage regulation and supports higher load currents without significant losses. These benefits make CCM preferred for applications requiring stable power delivery and high performance in DC-DC converters and power management systems.

Applications Suited for DCM Operation

DCM (Discontinuous Conduction Mode) operation suits applications requiring lightweight designs, such as low-power DC-DC converters, battery chargers, and LED drivers, where minimizing component stress and improving transient response is critical. This operation mode benefits systems with variable or light loads by enhancing efficiency at reduced currents, which is favorable for portable electronics and intermittent power supplies. Understanding your application's load profile helps determine if DCM is ideal for optimizing performance and energy savings.

Applications Suited for CCM Operation

Continuous Conduction Mode (CCM) operation is ideal for applications requiring a stable output current and reduced electromagnetic interference, such as power supplies for telecommunications and industrial motor drives. CCM maintains continuous inductor current, which ensures consistent energy delivery and improved efficiency in high-load or steady-state conditions. This mode is preferred in systems needing precise regulation and low ripple, including DC-DC converters for servers and electric vehicle powertrains.

Efficiency and Performance Comparison

DCM (Discontinuous Conduction Mode) operation often results in lower efficiency at higher load currents due to increased switching losses and current ripple, while CCM (Continuous Conduction Mode) provides more stable current flow, reducing stress on components and improving overall efficiency. CCM operation enhances performance in power converters by maintaining a steady inductor current, which minimizes output voltage ripple and supports better transient response. Your system's efficiency and reliability can be optimized by selecting CCM for high-load applications and DCM for light-load scenarios where switching frequency can be adjusted for reduced losses.

Selecting the Right Mode: Factors to Consider

Selecting the right mode between Discontinuous Conduction Mode (DCM) and Continuous Conduction Mode (CCM) depends on factors such as load current, switching frequency, and efficiency requirements. DCM is ideal for light loads and low current applications where switching losses are minimized, while CCM suits higher load currents with reduced conduction losses and better ripple performance. Your choice should balance efficiency, size constraints, and electromagnetic interference (EMI) considerations for optimal converter performance.

DCM operation vs CCM operation Infographic

electrown.com

electrown.com