DC chokes are designed to filter smooth direct current signals by blocking sudden changes in current, while AC chokes focus on reducing alternating current noise and harmonics in power supplies. Understanding the key differences between DC and AC chokes will help you choose the right component for your electrical project--read on to learn more.

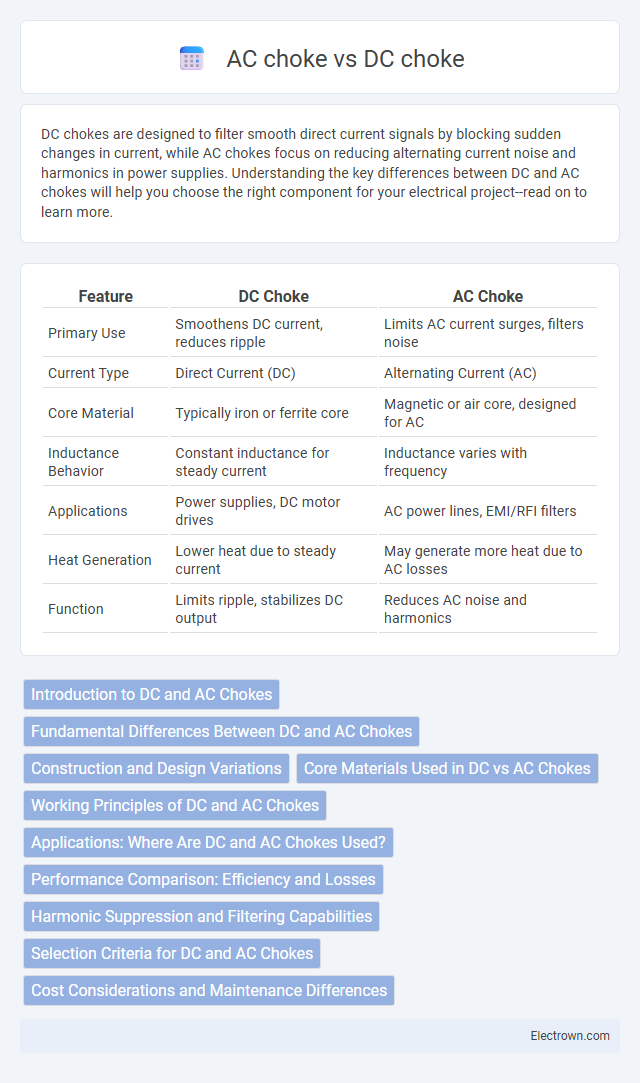

Table of Comparison

| Feature | DC Choke | AC Choke |

|---|---|---|

| Primary Use | Smoothens DC current, reduces ripple | Limits AC current surges, filters noise |

| Current Type | Direct Current (DC) | Alternating Current (AC) |

| Core Material | Typically iron or ferrite core | Magnetic or air core, designed for AC |

| Inductance Behavior | Constant inductance for steady current | Inductance varies with frequency |

| Applications | Power supplies, DC motor drives | AC power lines, EMI/RFI filters |

| Heat Generation | Lower heat due to steady current | May generate more heat due to AC losses |

| Function | Limits ripple, stabilizes DC output | Reduces AC noise and harmonics |

Introduction to DC and AC Chokes

DC chokes are inductors designed to smooth and filter direct current by opposing sudden changes in current flow, commonly used in power supplies and DC motor drives. AC chokes function by limiting AC ripple and noise in alternating current circuits, typically implemented in power factor correction and electromagnetic interference suppression. Both types optimize circuit performance by managing current stability and reducing electrical noise specific to their respective current forms.

Fundamental Differences Between DC and AC Chokes

DC chokes are designed to smooth and stabilize direct current flow by providing high inductance with minimal resistance, ideal for filtering and energy storage in DC circuits. AC chokes, however, are optimized to limit alternating current through impedance created by inductance and often include iron cores to enhance magnetic flux handling and reduce power losses. The fundamental difference lies in their handling of frequency and current direction; DC chokes operate with steady current and constant polarity, while AC chokes deal with alternating current that changes direction and magnitude periodically.

Construction and Design Variations

DC chokes typically feature a ferrite or laminated iron core designed to handle steady direct current without saturation, optimizing their inductance and thermal performance for DC circuits. AC chokes often utilize air cores or specialized laminated cores to minimize eddy currents and core losses in alternating current applications, allowing better performance at varying frequencies. The coil winding techniques also differ, with DC chokes emphasizing thicker wire for continuous current and AC chokes designed to reduce stray capacitance and maintain impedance stability under AC conditions.

Core Materials Used in DC vs AC Chokes

Core materials used in DC chokes typically include ferrite and powdered iron, chosen for their high magnetic permeability and low core losses at operating frequencies. AC chokes often utilize laminated silicon steel or ferrite cores to reduce eddy current losses and handle higher frequency variations found in alternating current applications. The selection of core material directly influences the choke's efficiency, inductance stability, and thermal performance in DC versus AC circuits.

Working Principles of DC and AC Chokes

DC chokes use inductors to resist changes in current by storing energy in a magnetic field when direct current passes through, effectively smoothing voltage fluctuations. AC chokes operate by introducing inductive reactance that opposes alternating current changes, filtering out high-frequency noise and harmonics in AC circuits. Both chokes rely on inductance, but DC chokes maintain steady current flow in DC systems, while AC chokes primarily attenuate unwanted frequencies in AC systems.

Applications: Where Are DC and AC Chokes Used?

DC chokes are primarily used in power supplies, DC motors, and battery-operated devices to smooth out current and reduce voltage spikes, enhancing efficiency and protecting circuits. AC chokes find applications in AC power lines, fluorescent lighting, and electromagnetic interference (EMI) filtering to limit inrush current and stabilize alternating current waveforms. Both types play crucial roles in electrical and electronic systems by improving performance and minimizing noise in their respective current types.

Performance Comparison: Efficiency and Losses

DC chokes typically exhibit lower core losses and higher efficiency at steady-state currents due to their design optimized for direct current applications, whereas AC chokes experience increased losses from core hysteresis and eddy currents induced by alternating magnetic fields. The efficiency of DC chokes remains more consistent across varying loads, while AC chokes may suffer efficiency drops at higher frequencies because of increased reactive power and heat dissipation. When selecting your choke for power filtering or noise reduction, consider that DC chokes generally provide superior performance in minimizing losses under constant current conditions.

Harmonic Suppression and Filtering Capabilities

DC chokes excel at harmonic suppression by reducing ripple currents in direct current circuits, resulting in smoother power delivery and enhanced filtering of high-frequency noise. AC chokes are designed to filter alternating current harmonics by impeding specific frequency components, effectively minimizing distortion and improving power quality. Your choice between DC and AC chokes should consider the specific harmonic spectrum and filtering requirements of your electrical system.

Selection Criteria for DC and AC Chokes

Selection criteria for DC and AC chokes depend primarily on their operating frequency and current requirements; DC chokes are optimized for steady direct current with low ripple, featuring high inductance and low DC resistance to minimize power loss. AC chokes must handle alternating current at specific frequencies, requiring careful consideration of core material to reduce core losses and prevent saturation under varying magnetic flux. Your choice should align with the electrical parameters of your circuit, including voltage, current, and frequency, ensuring the choke maintains efficiency and thermal stability.

Cost Considerations and Maintenance Differences

DC chokes generally have higher initial costs due to the need for specialized components like laminated iron cores and robust insulation to handle steady direct current. AC chokes tend to be less expensive and simpler to maintain because they use standard iron cores and experience lower thermal stress from alternating current cycles. Maintenance for DC chokes requires regular inspection for core saturation and insulation degradation, while AC chokes mainly demand routine checks for coil integrity and connection stability.

DC choke vs AC choke Infographic

electrown.com

electrown.com