H-bridge and T-bridge circuits are both used to control the direction of electric motors, but H-bridge configurations offer greater flexibility and simpler design for bidirectional control, while T-bridge circuits are typically preferred for specific applications with unique switching requirements. Discover the key differences and decide which bridge suits your project needs by reading the rest of the article.

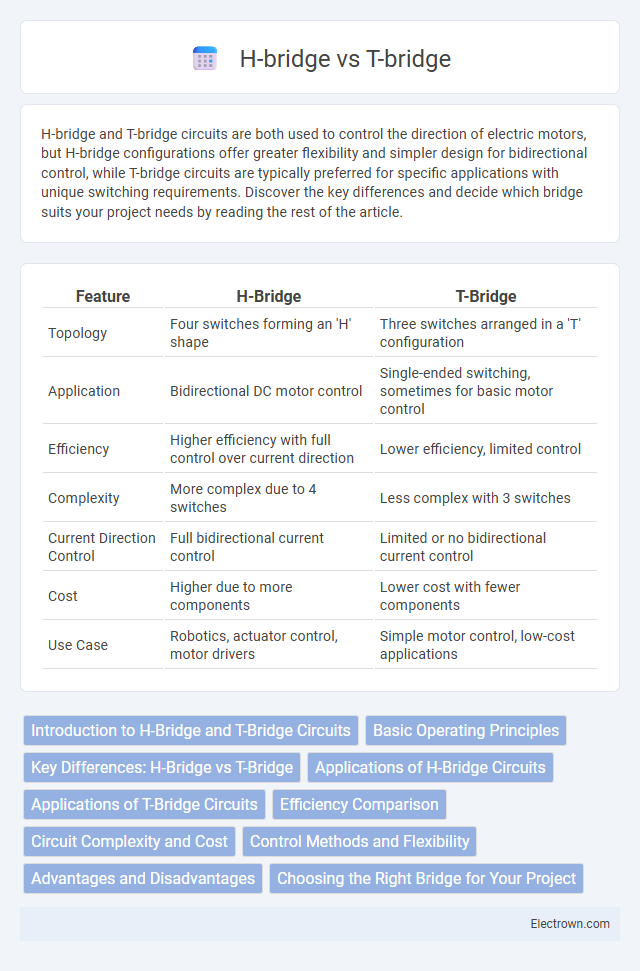

Table of Comparison

| Feature | H-Bridge | T-Bridge |

|---|---|---|

| Topology | Four switches forming an 'H' shape | Three switches arranged in a 'T' configuration |

| Application | Bidirectional DC motor control | Single-ended switching, sometimes for basic motor control |

| Efficiency | Higher efficiency with full control over current direction | Lower efficiency, limited control |

| Complexity | More complex due to 4 switches | Less complex with 3 switches |

| Current Direction Control | Full bidirectional current control | Limited or no bidirectional current control |

| Cost | Higher due to more components | Lower cost with fewer components |

| Use Case | Robotics, actuator control, motor drivers | Simple motor control, low-cost applications |

Introduction to H-Bridge and T-Bridge Circuits

H-bridge circuits utilize four switches arranged in an "H" configuration to control the direction of current flow through a load, enabling bidirectional motor control with efficient switching and minimal power loss. T-bridge circuits are less common and use a three-switch arrangement shaped like a "T" to manage current flow, often providing simpler implementation for specific applications like low-power motor driving. While H-bridges offer greater flexibility and control for complex motor operations, T-bridges are favored for their straightforward design and potentially reduced component count.

Basic Operating Principles

An H-bridge uses four switches arranged in an "H" configuration to control the direction of current flow through a load, enabling bidirectional control of a DC motor. The T-bridge, a less common topology, typically integrates three switches in a "T" shape to achieve similar directional control but often with simplified switching patterns. Understanding the basic operating principles of each allows you to select the optimal bridge configuration for precise motor control applications.

Key Differences: H-Bridge vs T-Bridge

H-Bridge circuits enable bidirectional control of DC motors by allowing current to flow in either direction, making them ideal for simple motor reversal applications. T-Bridge configurations incorporate an additional transistor for enhanced modulation and finer control over motor speed and torque, typically used in advanced motor driver designs. The key difference lies in the complexity and control precision, where H-Bridges offer straightforward direction control, while T-Bridges provide improved efficiency and smoother PWM-based speed regulation.

Applications of H-Bridge Circuits

H-bridge circuits are widely used in applications requiring bidirectional control of DC motors, such as robotics, electric vehicles, and industrial automation systems. These circuits enable precise motor speed and direction control by allowing current to flow in either direction through the motor windings. Your projects benefit from H-bridge designs when efficient, reversible power control is essential for dynamic motion and positioning tasks.

Applications of T-Bridge Circuits

T-Bridge circuits are primarily used in precision impedance measurements and sensor interfacing, offering enhanced sensitivity and stability in Wheatstone bridge configurations. These circuits enable accurate detection of small resistance changes, making them ideal for strain gauges, temperature sensors, and other transducers. T-Bridge setups also find applications in audio signal processing and calibration systems where balanced input impedance is critical.

Efficiency Comparison

H-bridge circuits generally exhibit higher efficiency due to their simpler design and lower conduction losses compared to T-bridge configurations. T-bridge topologies introduce additional switching elements that increase resistance and switching losses, reducing overall efficiency. Efficiency in H-bridges often exceeds 90%, while T-bridge designs typically operate slightly lower, especially under high current conditions.

Circuit Complexity and Cost

The H-bridge configuration exhibits moderate circuit complexity with four switches, making it cost-effective for bidirectional motor control. In contrast, the T-bridge topology involves additional components, increasing complexity and overall cost due to its segmented switching arrangement. Your choice depends on balancing simplicity and budget against specific performance requirements.

Control Methods and Flexibility

H-bridge circuits utilize four switches arranged in an H pattern to control motor direction and speed through pulse-width modulation (PWM), offering precise bidirectional control ideal for DC motors. T-bridge configurations, while less common, simplify control schemes by using fewer components but may limit flexibility in speed and directional control compared to H-bridges. Your choice depends on the required control complexity and flexibility, with H-bridges providing greater versatility for varied motor applications.

Advantages and Disadvantages

H-bridge circuits offer efficient bidirectional control of DC motors with relatively simple design and low cost but can suffer from higher power dissipation and limited voltage handling. T-bridge configurations provide improved switching performance and reduced power loss, making them suitable for high-current applications, though they are often more complex and expensive to implement. Your choice depends on the trade-off between control precision, cost, and power requirements in your specific motor control application.

Choosing the Right Bridge for Your Project

Selecting the right bridge for your project involves understanding the distinct advantages of H-bridge and T-bridge configurations. H-bridge circuits excel in controlling DC motors by providing bidirectional current flow, ensuring precise speed and direction control. T-bridge designs offer simpler layouts with fewer components but are usually limited to unidirectional current, making them ideal for straightforward applications where cost and simplicity are priorities.

H-bridge vs T-bridge Infographic

electrown.com

electrown.com