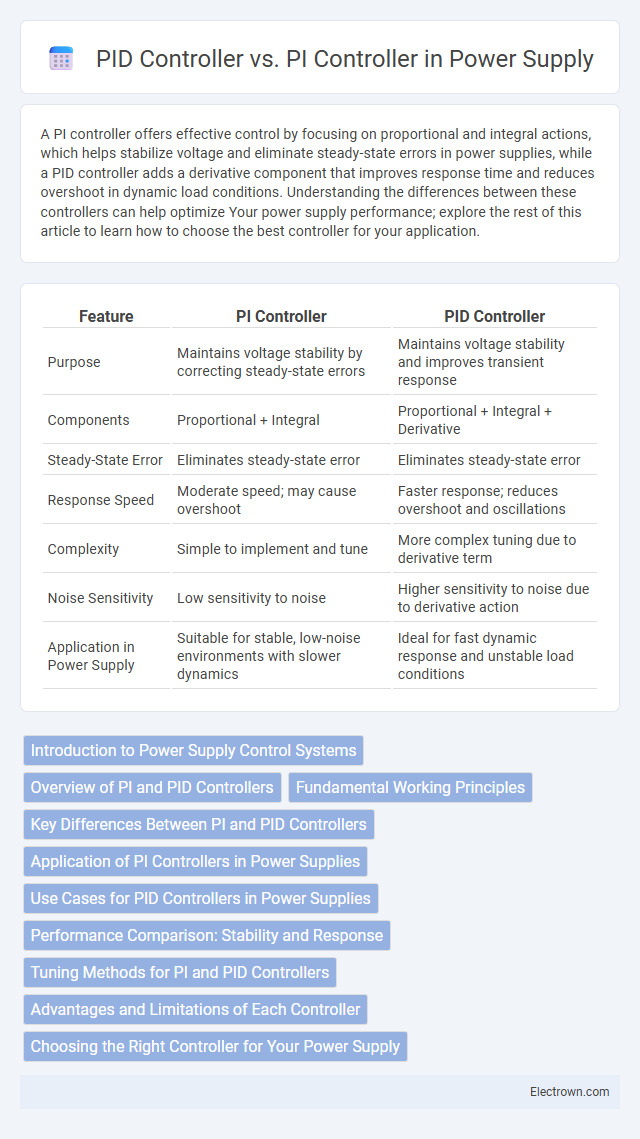

A PI controller offers effective control by focusing on proportional and integral actions, which helps stabilize voltage and eliminate steady-state errors in power supplies, while a PID controller adds a derivative component that improves response time and reduces overshoot in dynamic load conditions. Understanding the differences between these controllers can help optimize Your power supply performance; explore the rest of this article to learn how to choose the best controller for your application.

Table of Comparison

| Feature | PI Controller | PID Controller |

|---|---|---|

| Purpose | Maintains voltage stability by correcting steady-state errors | Maintains voltage stability and improves transient response |

| Components | Proportional + Integral | Proportional + Integral + Derivative |

| Steady-State Error | Eliminates steady-state error | Eliminates steady-state error |

| Response Speed | Moderate speed; may cause overshoot | Faster response; reduces overshoot and oscillations |

| Complexity | Simple to implement and tune | More complex tuning due to derivative term |

| Noise Sensitivity | Low sensitivity to noise | Higher sensitivity to noise due to derivative action |

| Application in Power Supply | Suitable for stable, low-noise environments with slower dynamics | Ideal for fast dynamic response and unstable load conditions |

Introduction to Power Supply Control Systems

PI controllers regulate voltage and current in power supply control systems by adjusting the proportional and integral gains to maintain stable output under varying loads. PID controllers enhance this regulation by adding a derivative term, which predicts future errors for improved transient response and reduced overshoot. Your selection between PI and PID hinges on the power supply's dynamic performance requirements and the complexity of load variations.

Overview of PI and PID Controllers

PI controllers in power supplies regulate voltage or current by eliminating steady-state errors using proportional and integral action, ensuring system stability and smooth output. PID controllers add a derivative component to PI control, improving transient response and reducing overshoot for more precise and rapid adjustments in dynamic load conditions. Your choice between PI and PID depends on the power supply's performance requirements and the complexity of the load regulation needed.

Fundamental Working Principles

The fundamental working principle of a PI controller in power supply regulation involves proportional and integral actions that eliminate steady-state error by adjusting output based on present and accumulated error values. A PID controller extends this by adding a derivative component, which predicts future error trends and enhances system stability and response time. Your choice between PI and PID controllers depends on the specific performance goals and dynamic requirements of the power supply system.

Key Differences Between PI and PID Controllers

PI controllers regulate voltage by adjusting proportional and integral actions to eliminate steady-state error in power supplies, offering simpler tuning and better stability for systems with slower dynamics. PID controllers incorporate a derivative term to predict system behavior, improving transient response and reducing overshoot in fast-changing power supply environments. Your choice depends on the desired balance between control precision and system complexity in power regulation.

Application of PI Controllers in Power Supplies

PI controllers in power supplies effectively regulate voltage and current by eliminating steady-state error while maintaining system stability. They are commonly applied in DC-DC converters and linear power supplies for maintaining precise output under varying load conditions. The simpler control algorithm of PI controllers ensures faster response and reduced computational complexity compared to PID controllers, making them suitable for systems where derivative action is unnecessary.

Use Cases for PID Controllers in Power Supplies

PID controllers in power supplies excel in maintaining precise voltage and current regulation under varying load conditions, ensuring stable output in sensitive electronics and industrial applications. They effectively manage transient responses and minimize overshoot, critical for high-performance power systems such as DC-DC converters and uninterruptible power supplies (UPS). The integral and derivative actions in PID controllers provide superior accuracy and rapid correction compared to PI controllers, making them ideal for dynamic and complex power supply environments.

Performance Comparison: Stability and Response

PI controllers offer stable regulation with minimal overshoot, making them suitable for steady-state voltage control in power supplies. PID controllers enhance response performance by adding a derivative term that predicts system behavior, resulting in faster settling times and improved transient stability. Your choice between PI and PID controllers depends on the required balance between stability and dynamic response in the power supply design.

Tuning Methods for PI and PID Controllers

Tuning methods for PI controllers in power supply systems often involve straightforward approaches like the Ziegler-Nichols or the Integral of Time-weighted Absolute Error (ITAE) technique, emphasizing proportional gain and integral time to minimize steady-state error. PID controllers require more complex tuning strategies such as the Cohen-Coon or relay feedback methods, which optimize proportional, integral, and derivative gains to improve transient response and stability. Advanced techniques including model-based optimization and adaptive tuning algorithms enhance performance by precisely adjusting parameters to system dynamics and load variations.

Advantages and Limitations of Each Controller

PI controllers in power supplies offer simplicity and stability, making them effective for steady-state error elimination and reduced overshoot, ideal for systems needing reliable voltage regulation. However, their limitation lies in slower response to rapid load changes due to lack of derivative action. PID controllers provide faster transient response and improved stability under varying loads by incorporating derivative control, yet they are more complex to tune and may introduce noise sensitivity, potentially complicating your power supply design.

Choosing the Right Controller for Your Power Supply

Selecting between a PI controller and a PID controller for your power supply hinges on the desired balance between simplicity and precision. PI controllers excel in systems where steady-state error elimination is critical and system dynamics are relatively slow, minimizing overshoot and simplifying tuning. PID controllers offer enhanced performance by adding derivative action to anticipate changes, improving transient response and stability in more complex or rapidly changing power supply environments.

pi controller vs pid controller in power supply Infographic

electrown.com

electrown.com