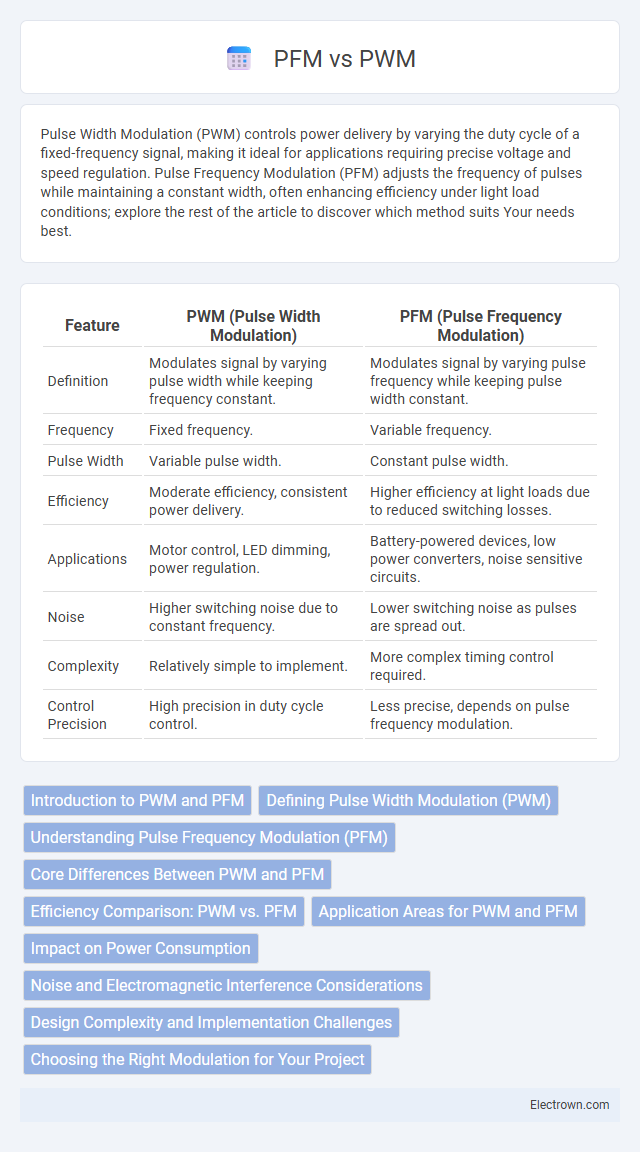

Pulse Width Modulation (PWM) controls power delivery by varying the duty cycle of a fixed-frequency signal, making it ideal for applications requiring precise voltage and speed regulation. Pulse Frequency Modulation (PFM) adjusts the frequency of pulses while maintaining a constant width, often enhancing efficiency under light load conditions; explore the rest of the article to discover which method suits Your needs best.

Table of Comparison

| Feature | PWM (Pulse Width Modulation) | PFM (Pulse Frequency Modulation) |

|---|---|---|

| Definition | Modulates signal by varying pulse width while keeping frequency constant. | Modulates signal by varying pulse frequency while keeping pulse width constant. |

| Frequency | Fixed frequency. | Variable frequency. |

| Pulse Width | Variable pulse width. | Constant pulse width. |

| Efficiency | Moderate efficiency, consistent power delivery. | Higher efficiency at light loads due to reduced switching losses. |

| Applications | Motor control, LED dimming, power regulation. | Battery-powered devices, low power converters, noise sensitive circuits. |

| Noise | Higher switching noise due to constant frequency. | Lower switching noise as pulses are spread out. |

| Complexity | Relatively simple to implement. | More complex timing control required. |

| Control Precision | High precision in duty cycle control. | Less precise, depends on pulse frequency modulation. |

Introduction to PWM and PFM

Pulse Width Modulation (PWM) controls power delivery by varying the duty cycle of a fixed frequency signal, optimizing efficiency in applications like motor control and LED dimming. Pulse Frequency Modulation (PFM), on the other hand, adjusts the frequency of pulses while maintaining a constant pulse width, enhancing performance in low-power scenarios such as battery-operated devices. Both methods regulate energy flow but differ in technique and ideal use cases, impacting thermal management and electromagnetic interference.

Defining Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) is a technique that controls power delivery by varying the width of voltage pulses while keeping the frequency constant, enabling efficient regulation of electrical devices. The duty cycle in PWM determines the average voltage output, directly influencing the performance and speed of motors or brightness of LEDs. Your choice of PWM ensures precise control with minimal power loss, making it ideal for applications requiring consistent power levels.

Understanding Pulse Frequency Modulation (PFM)

Pulse Frequency Modulation (PFM) varies the frequency of pulses to regulate power delivery efficiently, especially at light loads, reducing switching losses compared to Pulse Width Modulation (PWM), which changes pulse width at a constant frequency. Understanding PFM helps you optimize power management in applications requiring improved efficiency and reduced electromagnetic interference (EMI). PFM's adaptive switching frequency is ideal for battery-powered devices where energy conservation is critical.

Core Differences Between PWM and PFM

PWM (Pulse Width Modulation) controls power by varying the duty cycle of a constant frequency signal, ensuring consistent switching frequency and stable output voltage. PFM (Pulse Frequency Modulation) adjusts power by changing the switching frequency based on load demand, improving efficiency at light loads but causing variable output ripple. Your choice between PWM and PFM depends on whether you prioritize stable output with low ripple (PWM) or higher lightweight efficiency with variable frequency (PFM).

Efficiency Comparison: PWM vs. PFM

PWM (Pulse Width Modulation) generally offers higher efficiency at steady, high-load conditions by maintaining a constant switching frequency and minimizing switching losses. PFM (Pulse Frequency Modulation) improves efficiency during light-load conditions by reducing switching frequency and lowering quiescent current consumption. Overall, PFM excels in low-power scenarios, while PWM is preferred for consistent performance and thermal management under heavier loads.

Application Areas for PWM and PFM

PWM (Pulse Width Modulation) is widely used in applications requiring precise control of power delivery and motor speed, such as in motor drives, power inverters, and LED dimming systems. PFM (Pulse Frequency Modulation) excels in low-power, energy-efficient devices like battery-powered electronics and switching regulators, where reducing switching losses and improving efficiency at light loads is critical. Your choice between PWM and PFM depends on balancing factors like efficiency, noise, and load conditions specific to your application area.

Impact on Power Consumption

PWM (Pulse Width Modulation) delivers a consistent switching frequency with varying duty cycles, resulting in steady power delivery but potentially higher power consumption at low loads. PFM (Pulse Frequency Modulation) adjusts the switching frequency based on load demand, which significantly reduces switching losses and improves efficiency during light-load conditions. Your choice between PWM and PFM directly impacts battery life and overall power efficiency, especially in portable or energy-sensitive applications.

Noise and Electromagnetic Interference Considerations

PWM (Pulse Width Modulation) generates consistent switching frequencies, which can create predictable electromagnetic interference (EMI) patterns, allowing for more straightforward noise filtering and mitigation. PFM (Pulse Frequency Modulation) varies the switching frequency, reducing EMI peaks but potentially causing broader noise spectra that complicate EMI management. Your choice between PWM and PFM impacts noise suppression strategies and must balance predictable interference with overall EMI profile for optimal system performance.

Design Complexity and Implementation Challenges

Pulse Width Modulation (PWM) circuits exhibit moderate design complexity due to precise timing control requirements and maintaining consistent switching frequency, demanding careful selection of components and circuit layout to minimize electromagnetic interference. Pulse Frequency Modulation (PFM) introduces higher implementation challenges as variable switching frequency complicates filtering and noise management, requiring advanced algorithms and adaptive control strategies to optimize efficiency across dynamic load conditions. Designers must balance these factors by evaluating application-specific constraints such as power efficiency targets and electromagnetic compatibility standards.

Choosing the Right Modulation for Your Project

PWM (Pulse Width Modulation) offers precise control of power by varying the duty cycle, making it ideal for applications like motor speed control and LED dimming where consistent voltage regulation is crucial. PFM (Pulse Frequency Modulation) adjusts power delivery by changing the frequency of pulses, providing higher efficiency at light loads, which suits battery-powered and low-power devices. Selecting between PWM and PFM depends on balancing efficiency needs with output stability, ensuring optimal performance for your specific project requirements.

PWM vs PFM Infographic

electrown.com

electrown.com