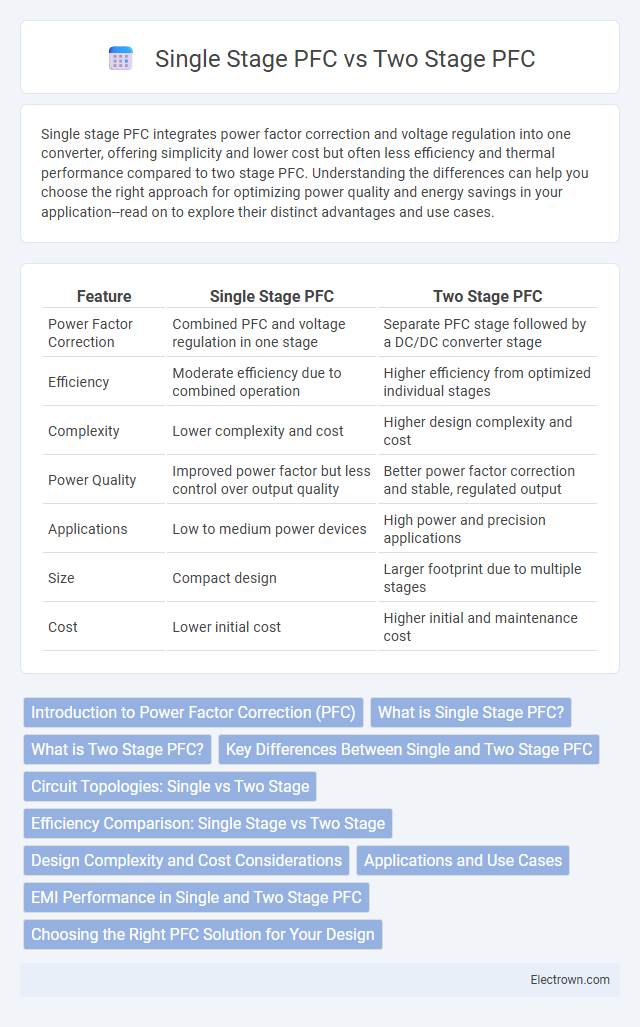

Single stage PFC integrates power factor correction and voltage regulation into one converter, offering simplicity and lower cost but often less efficiency and thermal performance compared to two stage PFC. Understanding the differences can help you choose the right approach for optimizing power quality and energy savings in your application--read on to explore their distinct advantages and use cases.

Table of Comparison

| Feature | Single Stage PFC | Two Stage PFC |

|---|---|---|

| Power Factor Correction | Combined PFC and voltage regulation in one stage | Separate PFC stage followed by a DC/DC converter stage |

| Efficiency | Moderate efficiency due to combined operation | Higher efficiency from optimized individual stages |

| Complexity | Lower complexity and cost | Higher design complexity and cost |

| Power Quality | Improved power factor but less control over output quality | Better power factor correction and stable, regulated output |

| Applications | Low to medium power devices | High power and precision applications |

| Size | Compact design | Larger footprint due to multiple stages |

| Cost | Lower initial cost | Higher initial and maintenance cost |

Introduction to Power Factor Correction (PFC)

Power Factor Correction (PFC) improves electrical efficiency by reducing reactive power in AC circuits, enhancing energy utilization and lowering utility costs. Single-stage PFC integrates power factor correction and voltage regulation within a single converter, offering compact design and cost-effectiveness but limited harmonic reduction. Two-stage PFC separates rectification and voltage regulation into distinct stages, enabling higher power quality, reduced total harmonic distortion (THD), and improved performance in high-power applications.

What is Single Stage PFC?

Single stage PFC (Power Factor Correction) integrates voltage regulation and power factor correction into one process, improving overall efficiency and reducing system complexity. It uses a single converter stage to correct power factor while also stabilizing output voltage, making it suitable for compact and cost-sensitive applications. Compared to two stage PFC, single stage designs often have lower components count and smaller footprint but may face challenges in achieving as precise power quality and lower harmonic distortion.

What is Two Stage PFC?

Two Stage Power Factor Correction (PFC) improves efficiency by dividing the correction process into two separate stages: a boost converter for high power factor and input current shaping, followed by a DC-DC converter for voltage regulation and isolation. This method enhances overall system performance by reducing harmonic distortion and improving power quality compared to Single Stage PFC, which combines both functions into one stage. Two Stage PFC is commonly used in high-power applications requiring stringent power quality standards and better thermal management.

Key Differences Between Single and Two Stage PFC

Single stage PFC integrates power factor correction and voltage regulation into one process, resulting in simpler design and lower cost but with limited efficiency and harmonic reduction. Two stage PFC separates these functions into a front-end boost converter followed by a DC-DC converter, offering improved power quality, higher efficiency, and better compliance with stringent power standards. Your choice depends on the application requirements, balancing cost, complexity, and performance.

Circuit Topologies: Single vs Two Stage

Single-stage PFC circuits integrate power factor correction and voltage regulation into one topology, typically using boost converters to achieve simplicity and cost-effectiveness. Two-stage PFC designs separate the power factor correction and DC-DC conversion into distinct stages, often employing a boost converter for PFC followed by a buck or isolated converter for voltage regulation, enhancing performance and efficiency. The two-stage approach enables better handling of input voltage fluctuations and stricter compliance with harmonic standards compared to single-stage solutions.

Efficiency Comparison: Single Stage vs Two Stage

Single stage PFC systems typically offer lower efficiency, ranging from 85% to 92%, due to their integrated correction and regulation in one circuit. Two stage PFC designs separate the power factor correction and voltage regulation, achieving higher efficiencies typically between 95% and 98%, which reduces power losses and improves thermal management. Your selection should consider that two stage PFC offers superior efficiency for high power applications, while single stage PFC may suffice for lower power or cost-sensitive designs.

Design Complexity and Cost Considerations

Single-stage PFC circuits offer simpler design architecture with fewer components, resulting in lower manufacturing costs and reduced PCB size compared to two-stage PFC systems. Two-stage PFC separates power factor correction and voltage regulation into distinct modules, increasing design complexity and material expenses due to additional passive and active components. The trade-off involves single-stage PFC's cost-effectiveness and ease of implementation versus two-stage PFC's superior performance in power quality and efficiency at a higher development investment.

Applications and Use Cases

Single stage PFC is ideal for consumer electronics and small appliances where space and cost constraints dominate, offering acceptable harmonic reduction and efficiency in simpler applications. Two stage PFC is preferred in industrial and high-power applications, such as server farms and electric vehicle chargers, where stringent compliance with power quality standards and higher energy efficiency are critical. Your choice depends on the specific power quality requirements, system complexity, and regulatory standards needing fulfillment.

EMI Performance in Single and Two Stage PFC

Single stage Power Factor Correction (PFC) circuits typically exhibit higher electromagnetic interference (EMI) due to the overlap of power factor correction and voltage regulation functions within a single converter stage, leading to increased switching noise. Two stage PFC designs, separating boost PFC and DC-DC conversion, provide improved EMI performance by isolating high-frequency switching noise and enabling more effective filtering and shielding techniques. This division reduces conducted and radiated EMI, making two stage PFC systems more compliant with stringent regulatory standards in industrial and consumer power supplies.

Choosing the Right PFC Solution for Your Design

Single stage PFC offers simplicity and cost-effectiveness with moderate efficiency, ideal for designs prioritizing compactness and lower initial investment. Two stage PFC solutions deliver higher power quality and improved efficiency, making them suitable for applications demanding stringent regulatory compliance and enhanced total harmonic distortion (THD) performance. Assess your design's power requirements, efficiency targets, and regulatory constraints to determine whether single or two stage PFC aligns best with your project goals.

single stage pfc vs two stage pfc Infographic

electrown.com

electrown.com