Thermistor inrush limiters and NTC inrush limiters both serve to protect circuits from sudden current surges, but thermistors typically offer more precise temperature control and quicker response times, while NTC (Negative Temperature Coefficient) limiters are valued for their simplicity and cost-effectiveness. Understanding the key differences in their operation and application will help you choose the best solution for your electrical system; read on to explore these components in detail.

Table of Comparison

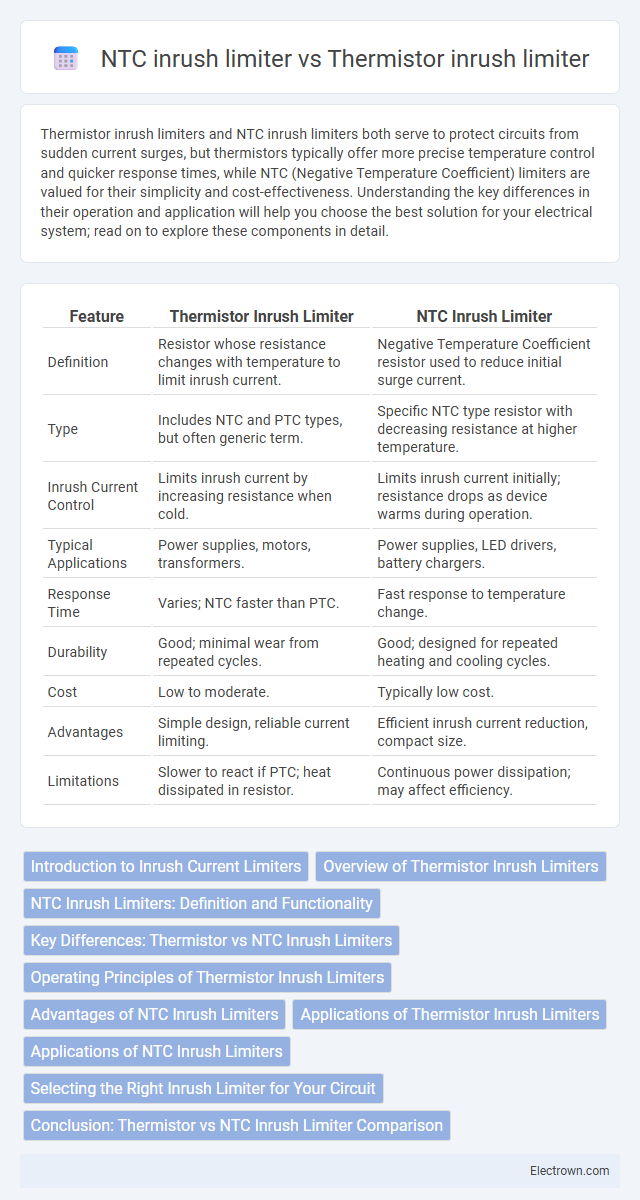

| Feature | Thermistor Inrush Limiter | NTC Inrush Limiter |

|---|---|---|

| Definition | Resistor whose resistance changes with temperature to limit inrush current. | Negative Temperature Coefficient resistor used to reduce initial surge current. |

| Type | Includes NTC and PTC types, but often generic term. | Specific NTC type resistor with decreasing resistance at higher temperature. |

| Inrush Current Control | Limits inrush current by increasing resistance when cold. | Limits inrush current initially; resistance drops as device warms during operation. |

| Typical Applications | Power supplies, motors, transformers. | Power supplies, LED drivers, battery chargers. |

| Response Time | Varies; NTC faster than PTC. | Fast response to temperature change. |

| Durability | Good; minimal wear from repeated cycles. | Good; designed for repeated heating and cooling cycles. |

| Cost | Low to moderate. | Typically low cost. |

| Advantages | Simple design, reliable current limiting. | Efficient inrush current reduction, compact size. |

| Limitations | Slower to react if PTC; heat dissipated in resistor. | Continuous power dissipation; may affect efficiency. |

Introduction to Inrush Current Limiters

Thermistor inrush limiters and NTC inrush limiters both manage the initial surge of current in electrical circuits to protect components and improve reliability. Thermistor inrush limiters are typically composed of resistive materials that change resistance with temperature, with NTC (Negative Temperature Coefficient) thermistors specifically exhibiting decreased resistance as temperature increases, providing efficient inrush current control. These devices reduce the risk of damage caused by high inrush currents in power supplies, motors, and electronic devices by gradually limiting current flow during startup.

Overview of Thermistor Inrush Limiters

Thermistor inrush limiters are specialized resistors that protect electrical circuits by restricting initial surge current during power-up, improving device longevity. These components dynamically change resistance with temperature, starting high to limit current and dropping as they heat, unlike fixed resistors. Your choice between thermistor and NTC (Negative Temperature Coefficient) inrush limiters depends on the specific thermal response and current handling requirements of your application.

NTC Inrush Limiters: Definition and Functionality

NTC inrush limiters are negative temperature coefficient thermistors designed to reduce high inrush currents by increasing resistance when cold and decreasing it as they warm up. Unlike standard thermistor inrush limiters, NTC devices provide a self-regulating response that protects circuits from current spikes during power-up, enhancing longevity and reliability. Your electronic systems benefit from NTC inrush limiters by maintaining stable current flow and preventing damage from sudden surges.

Key Differences: Thermistor vs NTC Inrush Limiters

Thermistor inrush limiters and NTC inrush limiters both regulate initial current surge but differ primarily in their material properties and response characteristics. Thermistor inrush limiters can refer to various types, such as PTC or NTC, but in this context, NTC (Negative Temperature Coefficient) thermistors specifically decrease resistance as temperature rises, allowing controlled current flow. The key distinction lies in usage: NTC inrush limiters often provide a predictable, temperature-dependent resistance drop for smooth current increase, while other thermistor types may have different applications and response behaviors in managing inrush current.

Operating Principles of Thermistor Inrush Limiters

Thermistor inrush limiters operate based on the principle of negative temperature coefficient (NTC), where their resistance decreases as temperature rises due to current flow. Initially, they provide high resistance to limit the surge current when power is first applied, protecting circuits from damage. You benefit from a self-regulating mechanism that allows the thermistor to cool and reset once the inrush current subsides.

Advantages of NTC Inrush Limiters

NTC inrush limiters offer superior self-regulating thermal characteristics that reduce power dissipation as the device heats up, enhancing energy efficiency. Their compact size and simple integration make them ideal for protecting sensitive electronic components against high surge currents during power-up. You benefit from increased reliability and prolonged device lifespan due to their effective current limiting and automatic reset features.

Applications of Thermistor Inrush Limiters

Thermistor inrush limiters, commonly made from NTC (Negative Temperature Coefficient) thermistors, are widely used in power supply circuits to manage high initial current surges during device startup. Applications include protecting sensitive components in consumer electronics, industrial equipment, and automotive systems by reducing stress on power switches and extending component life. Their ability to self-regulate resistance based on temperature makes them ideal for energy-efficient and cost-effective inrush current control solutions.

Applications of NTC Inrush Limiters

NTC inrush limiters are widely used in power supplies, LED drivers, and household appliances to prevent high current surges during device startup, protecting sensitive components and extending lifespan. These thermistor-based devices are especially effective in controlling initial current spikes in AC/DC converters and electric motors, ensuring smooth operation and reducing the risk of circuit damage. Their ability to quickly reduce resistance after startup makes NTC inrush limiters a preferred choice for energy-efficient and reliable electronic designs.

Selecting the Right Inrush Limiter for Your Circuit

Thermistor inrush limiters and NTC inrush limiters both serve to reduce initial current surges, but selecting the right inrush limiter for your circuit depends on factors like response time, operating temperature, and load current. NTC inrush limiters typically offer faster resistance change and are ideal for circuits requiring quick stabilization, while thermistor limiters provide more precise temperature-dependent current control suitable for sensitive components. Your choice should align with the specific thermal characteristics and electrical demands of the application to ensure optimal protection and performance.

Conclusion: Thermistor vs NTC Inrush Limiter Comparison

Thermistor inrush limiters and NTC inrush limiters both use negative temperature coefficient materials to restrict initial current surge, but NTC inrush limiters are specifically designed for rapid response and improved durability under thermal stress. Thermistors generally offer precise temperature sensing capabilities, making them suitable for applications where thermal measurement and current limiting are both required. NTC inrush limiters provide more efficient current control with quicker recovery times, optimizing protection for sensitive electronic circuits during power-up events.

Thermistor inrush limiter vs NTC inrush limiter Infographic

electrown.com

electrown.com