DC link capacitors are designed to stabilize and filter the DC voltage in power electronics circuits, typically featuring high capacitance and low ESR to support high ripple currents. Understanding the differences between DC link and AC coupling capacitors can help you optimize your circuit's performance; read on to explore their specific applications and characteristics.

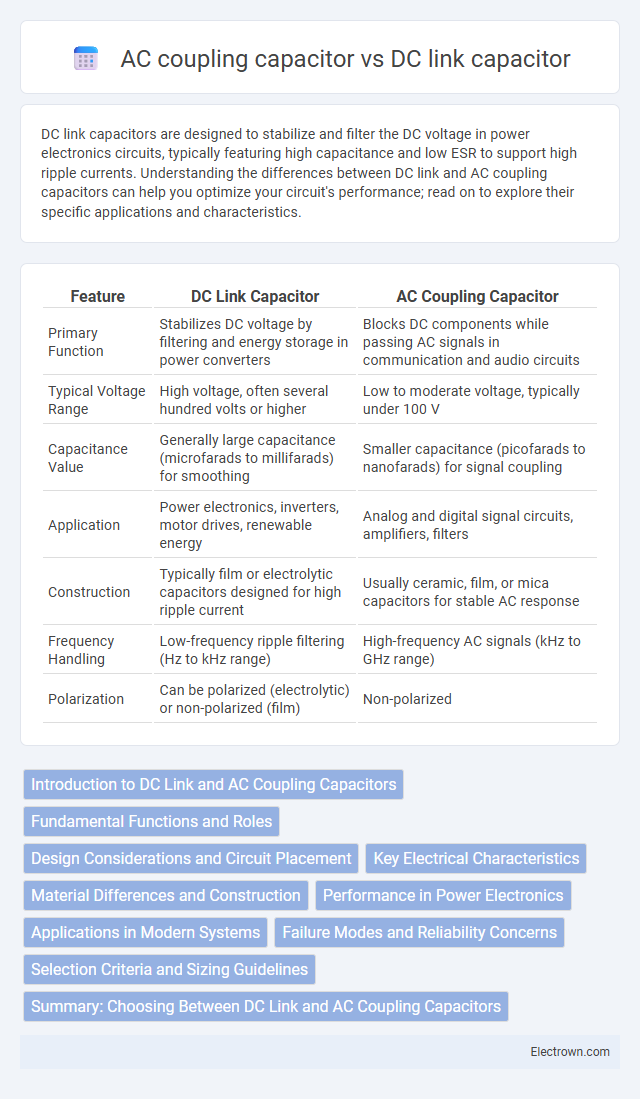

Table of Comparison

| Feature | DC Link Capacitor | AC Coupling Capacitor |

|---|---|---|

| Primary Function | Stabilizes DC voltage by filtering and energy storage in power converters | Blocks DC components while passing AC signals in communication and audio circuits |

| Typical Voltage Range | High voltage, often several hundred volts or higher | Low to moderate voltage, typically under 100 V |

| Capacitance Value | Generally large capacitance (microfarads to millifarads) for smoothing | Smaller capacitance (picofarads to nanofarads) for signal coupling |

| Application | Power electronics, inverters, motor drives, renewable energy | Analog and digital signal circuits, amplifiers, filters |

| Construction | Typically film or electrolytic capacitors designed for high ripple current | Usually ceramic, film, or mica capacitors for stable AC response |

| Frequency Handling | Low-frequency ripple filtering (Hz to kHz range) | High-frequency AC signals (kHz to GHz range) |

| Polarization | Can be polarized (electrolytic) or non-polarized (film) | Non-polarized |

Introduction to DC Link and AC Coupling Capacitors

DC link capacitors stabilize voltage by storing and filtering direct current in power electronics, enabling smooth energy transfer between converters. AC coupling capacitors block DC components while allowing alternating currents to pass, essential for signal integrity and noise reduction in communication systems. Your choice between these capacitors depends on whether you need to manage DC voltage stability or facilitate AC signal transmission in your application.

Fundamental Functions and Roles

DC link capacitors store and stabilize energy between the rectifier and inverter in power electronics, providing a smooth DC voltage and minimizing voltage ripple. AC coupling capacitors block DC components while allowing alternating current signals to pass, essential for signal integrity in communication and audio applications. Their fundamental roles differ as DC link capacitors manage power flow and energy buffering, whereas AC coupling capacitors facilitate signal transmission without DC bias.

Design Considerations and Circuit Placement

DC link capacitors require careful design considerations to handle high ripple currents and DC voltage levels, necessitating low equivalent series resistance (ESR) and robust thermal management to ensure reliability in power electronics such as inverters and motor drives. AC coupling capacitors are designed primarily for blocking DC components while allowing AC signals to pass, with placement typically between stages in amplifier circuits or communication lines to stabilize bias points and prevent DC offset propagation. Circuit placement for DC link capacitors is close to switching devices to minimize loop inductance and ensure efficient energy buffering, whereas AC coupling capacitors are positioned at input or output interfaces to maintain signal integrity without affecting DC operating points.

Key Electrical Characteristics

DC link capacitors exhibit high capacitance values, low equivalent series resistance (ESR), and the ability to handle high ripple currents, making them ideal for energy storage and smoothing in power converters. AC coupling capacitors typically have lower capacitance and higher voltage ratings, optimized for blocking DC components while allowing AC signals to pass without distortion. Your choice will depend on the application's voltage tolerance, frequency response, and thermal performance requirements.

Material Differences and Construction

DC link capacitors typically use polypropylene film or metallized film materials, providing low equivalent series resistance (ESR) and high voltage handling to manage steady DC voltage in power electronics. AC coupling capacitors often employ ceramic or aluminum electrolytic materials optimized for high-frequency AC signals and effective signal coupling without DC bias. Construction-wise, DC link capacitors feature robust casing for thermal management and high ripple current capacity, whereas AC coupling capacitors prioritize compactness and dielectric properties suited for signal integrity.

Performance in Power Electronics

DC link capacitors exhibit superior energy storage and filtering capabilities, enabling stable DC voltage levels with low equivalent series resistance (ESR) and high ripple current tolerance essential for efficient power conversion. AC coupling capacitors primarily block DC components while allowing AC signals to pass, but they lack the robust energy buffering and low-loss characteristics required in high-power electronics. High-performance power electronics favor DC link capacitors for their enhanced thermal stability, durability under high-frequency switching, and ability to smooth DC bus voltage, improving overall system efficiency and lifespan.

Applications in Modern Systems

DC link capacitors are essential in power electronics, stabilizing voltage and filtering ripples in DC bus systems of inverters, motor drives, and renewable energy converters. AC coupling capacitors are vital in signal processing for blocking DC components while allowing alternating current signals to pass in communication circuits, audio equipment, and instrumentation. The choice between DC link and AC coupling capacitors depends on the application's voltage requirements, frequency response, and energy storage needs in modern electronic systems.

Failure Modes and Reliability Concerns

DC link capacitors often face failure modes such as dielectric breakdown, electrolyte drying out, and increased equivalent series resistance (ESR), leading to reduced filtering efficiency and potential circuit instability. AC coupling capacitors typically experience failure due to thermal stress, insulation degradation, and mechanical fatigue, which can cause signal distortion and reduced lifespan. Reliability concerns for both capacitor types emphasize proper derating, temperature management, and quality of dielectric materials to ensure long-term operational stability.

Selection Criteria and Sizing Guidelines

DC link capacitors require selection based on voltage rating, ripple current capacity, and dielectric material to ensure stable DC bus voltage and filter high-frequency noise in power converters. AC coupling capacitors demand careful sizing by considering capacitance value, reactive power impact, and frequency response to block DC components while allowing AC signals to pass efficiently. Your design should balance thermal performance and physical size constraints to achieve optimal reliability and functionality for either type.

Summary: Choosing Between DC Link and AC Coupling Capacitors

DC link capacitors are designed to stabilize voltage and store energy in power electronic circuits, offering high capacitance and low equivalent series resistance (ESR) to enhance performance in DC bus applications. AC coupling capacitors block DC components while allowing AC signals to pass, commonly used in signal processing and filtering to prevent DC bias in AC circuits. Selecting between DC link and AC coupling capacitors depends on application requirements such as energy storage, voltage stabilization, and frequency filtering.

DC link capacitor vs AC coupling capacitor Infographic

electrown.com

electrown.com