Integrated photonics offers a compact, efficient way to manipulate light on a chip, significantly reducing size and power consumption compared to bulky traditional bulk optics setups. Discover how your applications can benefit from this transformative technology by exploring the rest of the article.

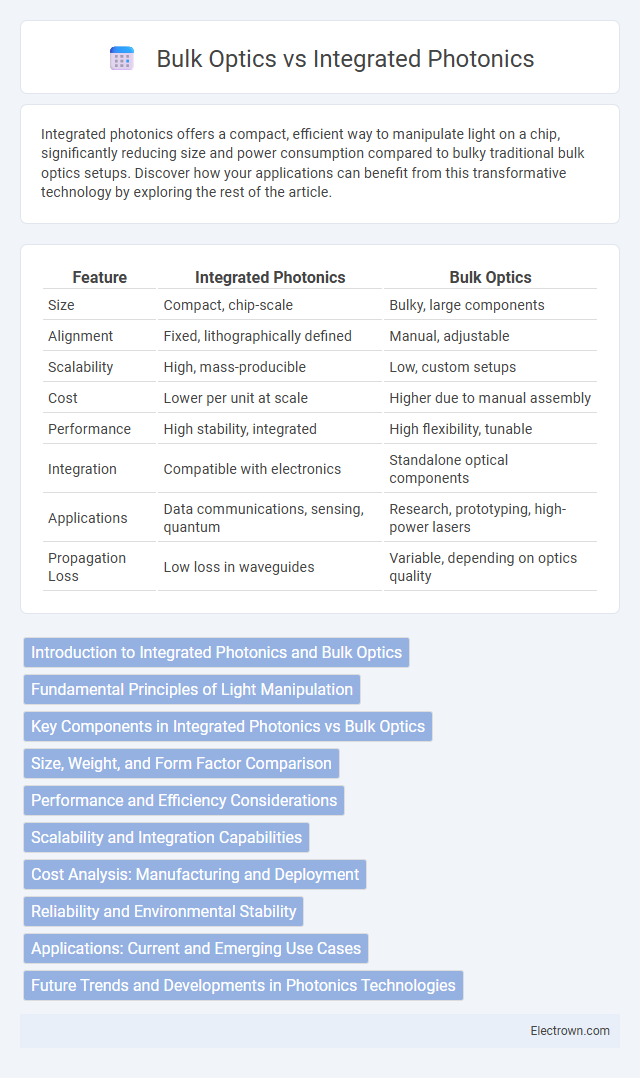

Table of Comparison

| Feature | Integrated Photonics | Bulk Optics |

|---|---|---|

| Size | Compact, chip-scale | Bulky, large components |

| Alignment | Fixed, lithographically defined | Manual, adjustable |

| Scalability | High, mass-producible | Low, custom setups |

| Cost | Lower per unit at scale | Higher due to manual assembly |

| Performance | High stability, integrated | High flexibility, tunable |

| Integration | Compatible with electronics | Standalone optical components |

| Applications | Data communications, sensing, quantum | Research, prototyping, high-power lasers |

| Propagation Loss | Low loss in waveguides | Variable, depending on optics quality |

Introduction to Integrated Photonics and Bulk Optics

Integrated photonics leverages miniature photonic circuits on semiconductor chips to manipulate light with high precision, enabling compact, scalable, and energy-efficient optical systems compared to bulk optics. Bulk optics relies on discrete components like lenses, mirrors, and beamsplitters, offering flexibility and ease of alignment but often resulting in larger size and increased sensitivity to environmental factors. The shift toward integrated photonics supports advancements in telecommunications, sensing, and quantum computing by providing enhanced performance in size, weight, and power consumption over traditional bulk optical setups.

Fundamental Principles of Light Manipulation

Integrated photonics manipulates light by confining it within waveguides on a chip, enabling precise control of phase, polarization, and amplitude through miniaturized optical elements. Bulk optics relies on free-space propagation of light through discrete components like lenses and mirrors, allowing manipulation based on geometric optics principles but with larger footprint and susceptibility to alignment issues. Your choice between these technologies depends on the required integration density, stability, and scalability for specific light manipulation applications.

Key Components in Integrated Photonics vs Bulk Optics

Integrated photonics incorporates waveguides, modulators, detectors, and multiplexers on a single chip platform, enabling compact and scalable optical circuits. Bulk optics relies on discrete components like lenses, mirrors, beam splitters, and free-space optical fibers, which offer greater flexibility but increase system size and alignment complexity. The integration of photonic components on silicon substrates allows for mass production and enhanced stability compared to the manual assembly and alignment required in bulk optic systems.

Size, Weight, and Form Factor Comparison

Integrated photonics offers a significant advantage over bulk optics in size, weight, and form factor, enabling miniaturized devices with footprints often reduced by orders of magnitude. The compact architecture of integrated photonic chips eliminates bulky lenses and mirrors, resulting in lighter systems ideal for portable and space-constrained applications. Your design benefits from enhanced robustness and scalability due to the monolithic integration of multiple optical functions on a single chip.

Performance and Efficiency Considerations

Integrated photonics offers superior performance and efficiency compared to bulk optics by enabling compact, scalable, and low-loss light manipulation on a chip-scale platform. The high index contrast in materials such as silicon or indium phosphide allows for strong optical confinement, resulting in reduced power consumption and enhanced signal integrity. Bulk optics suffer from larger footprints and alignment sensitivities, leading to higher insertion losses and lower overall system efficiency in complex optical setups.

Scalability and Integration Capabilities

Integrated photonics offers unparalleled scalability and integration capabilities compared to bulk optics, enabling the combination of multiple optical components on a single chip with high precision. This miniaturization allows for mass production and complex system architectures that bulk optics cannot achieve due to size and alignment limitations. Your optical systems benefit from reduced footprint, improved performance, and enhanced functionality through integrated photonics technology.

Cost Analysis: Manufacturing and Deployment

Integrated photonics significantly reduces manufacturing and deployment costs compared to bulk optics by leveraging scalable semiconductor fabrication processes, which enable mass production with high precision and repeatability. Bulk optics involve expensive materials, complex alignment procedures, and larger space requirements, increasing both the initial investment and maintenance expenses. Your projects benefit from integrated photonics through compact designs that lower packaging and assembly costs while enhancing reliability and integration with electronic components.

Reliability and Environmental Stability

Integrated photonics offers superior reliability and environmental stability compared to bulk optics due to its compact, monolithic design, which minimizes alignment sensitivity and mechanical vibrations. The use of semiconductor materials in integrated photonic devices enables consistent performance under varying temperature and humidity conditions, unlike bulk optical components that can suffer from misalignment and degradation over time. These inherent robustness features make integrated photonics ideal for harsh environments and long-term applications requiring stable optical signal transmission.

Applications: Current and Emerging Use Cases

Integrated photonics enables compact, high-speed data transmission in telecommunications and data centers, while bulk optics remains prevalent in laser systems and precision instrumentation. Emerging applications of integrated photonics include quantum computing, LiDAR for autonomous vehicles, and biosensing, offering scalability and enhanced performance. Bulk optics continues to serve in high-power laser applications and advanced microscopy, where large apertures and flexible configurations are critical.

Future Trends and Developments in Photonics Technologies

Integrated photonics is poised to revolutionize future photonics technologies by enabling miniaturization, increased performance, and cost-efficiency compared to traditional bulk optics. Emerging developments in silicon photonics, heterogeneous integration, and advanced fabrication techniques facilitate high-density photonic circuits with enhanced functionality for applications in telecommunications, quantum computing, and sensing. Continued innovation in materials science and photonic design promises to drive widespread adoption of integrated photonics, significantly advancing processing speeds and energy efficiency beyond the limitations of bulk optical systems.

integrated photonics vs bulk optics Infographic

electrown.com

electrown.com