Quantum dot lasers offer superior wavelength tunability and reduced temperature sensitivity compared to fiber lasers, making them ideal for high-precision applications. Explore the rest of the article to understand how these laser technologies compare and which one suits your specific needs.

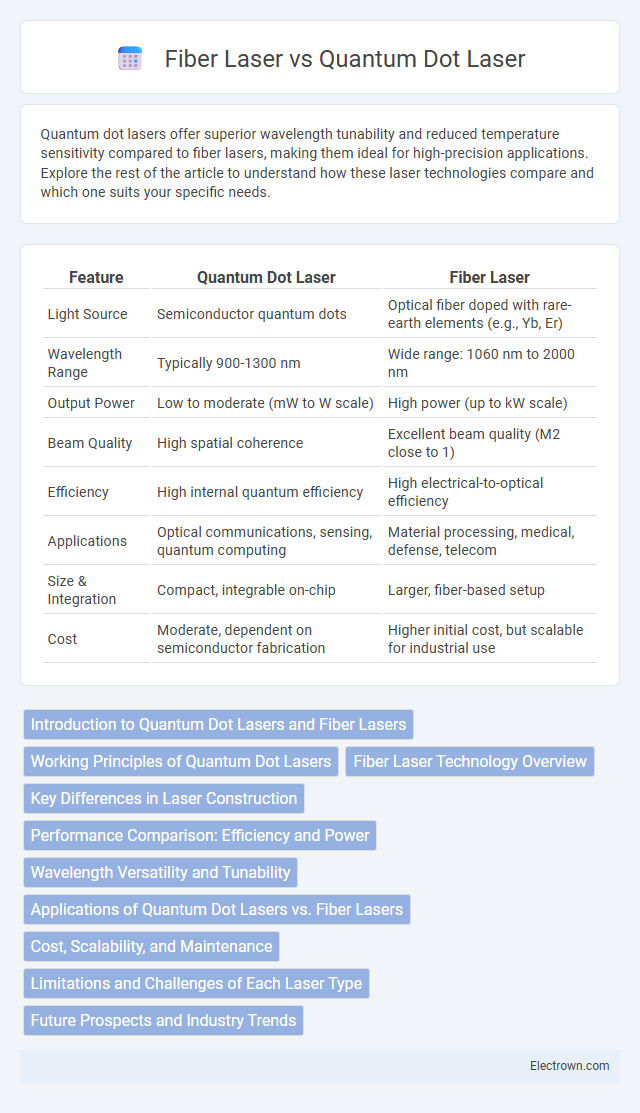

Table of Comparison

| Feature | Quantum Dot Laser | Fiber Laser |

|---|---|---|

| Light Source | Semiconductor quantum dots | Optical fiber doped with rare-earth elements (e.g., Yb, Er) |

| Wavelength Range | Typically 900-1300 nm | Wide range: 1060 nm to 2000 nm |

| Output Power | Low to moderate (mW to W scale) | High power (up to kW scale) |

| Beam Quality | High spatial coherence | Excellent beam quality (M2 close to 1) |

| Efficiency | High internal quantum efficiency | High electrical-to-optical efficiency |

| Applications | Optical communications, sensing, quantum computing | Material processing, medical, defense, telecom |

| Size & Integration | Compact, integrable on-chip | Larger, fiber-based setup |

| Cost | Moderate, dependent on semiconductor fabrication | Higher initial cost, but scalable for industrial use |

Introduction to Quantum Dot Lasers and Fiber Lasers

Quantum dot lasers use semiconductor nanocrystals to achieve superior temperature stability, low threshold currents, and high modulation speeds compared to traditional lasers. Fiber lasers rely on optical fibers doped with rare-earth elements, offering high beam quality, excellent power scalability, and robust efficiency for industrial and medical applications. Your choice between these technologies depends on specific needs like wavelength precision, power output, and application environment.

Working Principles of Quantum Dot Lasers

Quantum dot lasers operate by confining electrons and holes in nanoscale semiconductor particles, allowing for discrete energy states and enhanced quantum efficiency. These lasers leverage quantum confinement effects to produce coherent light with lower threshold currents and improved temperature stability compared to traditional fiber lasers. Understanding the working principles of quantum dot lasers can help you choose the right laser technology for applications requiring precise wavelength control and energy efficiency.

Fiber Laser Technology Overview

Fiber laser technology utilizes a pumped optical fiber doped with rare-earth elements such as ytterbium or erbium to generate high-power, coherent light with exceptional beam quality and efficiency. Compared to quantum dot lasers, fiber lasers offer superior thermal management, higher output power, and greater durability for industrial applications like cutting, welding, and marking. Your choice depends on the required precision, power scalability, and operational robustness, with fiber lasers excelling in high-power and long-distance beam delivery scenarios.

Key Differences in Laser Construction

Quantum dot lasers utilize nanoscale semiconductor particles as the gain medium, allowing for discrete energy states and improved temperature stability, while fiber lasers employ a doped optical fiber as the gain medium, providing excellent beam quality and high power output. The construction of quantum dot lasers involves intricate quantum well structures layered with quantum dots, enabling wavelength tunability and reduced threshold currents. In contrast, fiber lasers feature long, flexible fiber coils pumped by laser diodes, offering robust thermal management and compact design, making them ideal for industrial and medical applications.

Performance Comparison: Efficiency and Power

Quantum dot lasers exhibit superior efficiency due to their discrete energy levels, resulting in lower threshold currents and reduced heat generation compared to fiber lasers. Fiber lasers deliver higher power output and excellent beam quality, making them ideal for high-precision industrial applications. Your choice depends on whether efficiency or high power is the priority for the specific laser application.

Wavelength Versatility and Tunability

Quantum dot lasers exhibit superior wavelength versatility and tunability due to their discrete energy states, enabling precise emission across a broad spectral range from the visible to infrared. Fiber lasers, while typically operating at fixed wavelengths determined by the gain medium, offer limited tunability mostly through fiber composition and external modulators. Your choice depends on whether you prioritize dynamic wavelength control with quantum dot lasers or stable, high-power output at specific wavelengths with fiber lasers.

Applications of Quantum Dot Lasers vs. Fiber Lasers

Quantum dot lasers excel in telecommunications, optical data storage, and medical diagnostics due to their tunable emission wavelengths and low threshold currents. Fiber lasers dominate in industrial cutting, welding, and precision machining, offering high power output and excellent beam quality. The choice between quantum dot and fiber lasers depends on specific application requirements such as output power, wavelength stability, and device integration.

Cost, Scalability, and Maintenance

Quantum dot lasers offer lower manufacturing costs due to simpler semiconductor fabrication processes compared to fiber lasers, which require expensive rare-earth-doped fibers and precision splicing. Scalability favors fiber lasers as they can achieve higher power outputs by coherently combining multiple fibers, while quantum dot lasers face challenges in power scaling due to heat dissipation limits. Maintenance for quantum dot lasers is generally less intensive thanks to their compact, solid-state design, whereas fiber lasers demand regular fiber cleaning and alignment to maintain optimal performance.

Limitations and Challenges of Each Laser Type

Quantum dot lasers face challenges such as limited output power and temperature sensitivity, which can impact their performance in high-demand applications. Fiber lasers are constrained by nonlinear optical effects and the complexity of managing heat dissipation in high-power systems, potentially limiting efficiency and beam quality. Understanding these limitations is crucial for optimizing Your choice based on specific industrial or research needs.

Future Prospects and Industry Trends

Quantum dot lasers exhibit promising future prospects due to their enhanced wavelength tunability, lower threshold currents, and improved temperature stability, making them ideal for next-generation telecommunications and quantum computing applications. Fiber lasers continue to dominate high-power industrial sectors with advancements in efficiency, beam quality, and scalability, driving trends in materials processing and medical technologies. Your choice between these laser types should consider evolving industry demands for precision, energy efficiency, and integration in photonic systems.

quantum dot laser vs fiber laser Infographic

electrown.com

electrown.com