Spin pumping involves the generation of a spin current by a precessing magnetization that transfers angular momentum to an adjacent non-magnetic layer, while spin transfer torque refers to the phenomenon where a spin-polarized current influences the magnetization dynamics of a ferromagnet. Understanding these mechanisms is essential for advancing spintronic devices, and you can explore their differences and applications further in the rest of this article.

Table of Comparison

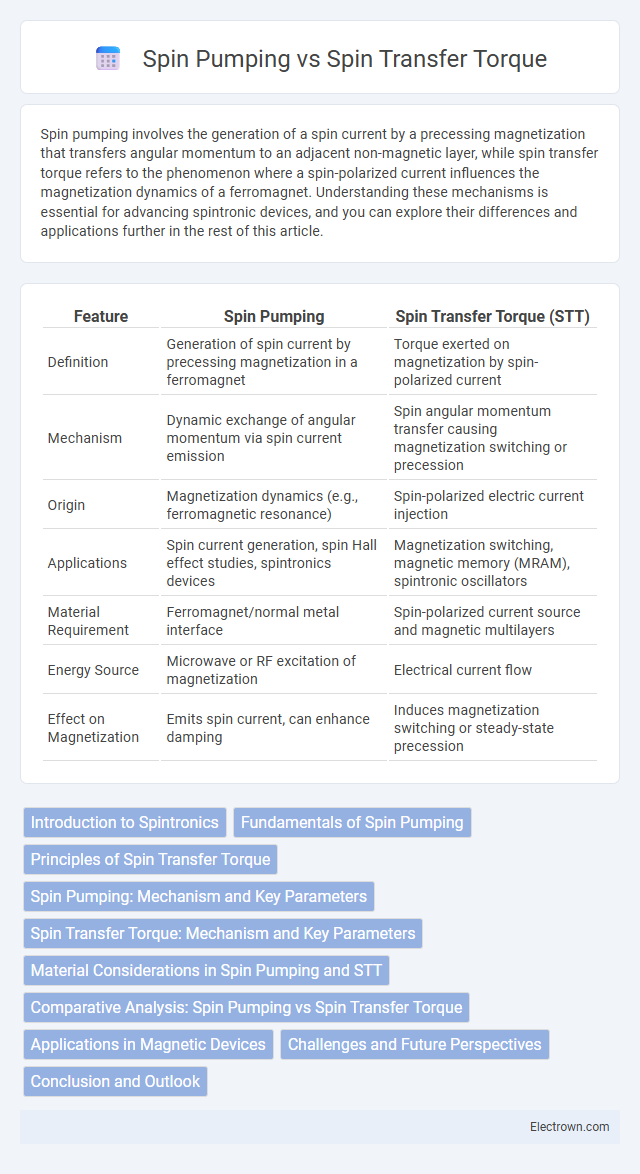

| Feature | Spin Pumping | Spin Transfer Torque (STT) |

|---|---|---|

| Definition | Generation of spin current by precessing magnetization in a ferromagnet | Torque exerted on magnetization by spin-polarized current |

| Mechanism | Dynamic exchange of angular momentum via spin current emission | Spin angular momentum transfer causing magnetization switching or precession |

| Origin | Magnetization dynamics (e.g., ferromagnetic resonance) | Spin-polarized electric current injection |

| Applications | Spin current generation, spin Hall effect studies, spintronics devices | Magnetization switching, magnetic memory (MRAM), spintronic oscillators |

| Material Requirement | Ferromagnet/normal metal interface | Spin-polarized current source and magnetic multilayers |

| Energy Source | Microwave or RF excitation of magnetization | Electrical current flow |

| Effect on Magnetization | Emits spin current, can enhance damping | Induces magnetization switching or steady-state precession |

Introduction to Spintronics

Spin pumping and spin transfer torque are fundamental mechanisms in spintronics, enabling the manipulation of electron spin for advanced data storage and processing. Spin pumping generates a spin current by dynamic magnetization in ferromagnets, while spin transfer torque uses spin-polarized currents to alter magnetic states directly. Understanding these phenomena helps optimize your devices for faster, energy-efficient magnetic memory and logic applications.

Fundamentals of Spin Pumping

Spin pumping is a phenomenon where a precessing magnetization in a ferromagnetic layer generates a pure spin current into an adjacent nonmagnetic material without charge flow, enhancing spin angular momentum transfer. The efficiency of spin pumping depends on the dynamic exchange interaction at the ferromagnet/nonmagnet interface and the spin mixing conductance, which governs the spin current amplitude. Understanding these fundamentals allows you to manipulate spin currents in spintronic devices, optimizing their performance through controlled magnetization dynamics.

Principles of Spin Transfer Torque

Spin Transfer Torque (STT) relies on the transfer of angular momentum from a spin-polarized current to a localized magnetic moment, causing the magnetization direction to switch or precess. This phenomenon occurs when conduction electrons with aligned spins interact with the magnetic layers in ferromagnetic materials, enabling efficient control of magnetic states in spintronic devices. Unlike spin pumping, which generates spin currents through dynamic magnetization, STT directly manipulates magnetization using electrical currents for applications in magnetic random-access memory (MRAM) and spin-torque oscillators.

Spin Pumping: Mechanism and Key Parameters

Spin pumping generates a pure spin current by dynamic magnetization in a ferromagnet under ferromagnetic resonance, transferring angular momentum to an adjacent nonmagnetic layer. Key parameters influencing spin pumping efficiency include the spin mixing conductance at the interface, the precession cone angle, and the Gilbert damping factor, which dictates the energy dissipation rate during magnetization dynamics. Understanding these factors helps optimize your spintronic device performance by enhancing spin current injection without charge flow.

Spin Transfer Torque: Mechanism and Key Parameters

Spin Transfer Torque (STT) is a quantum mechanical phenomenon where the angular momentum from a spin-polarized current exerts a torque on the local magnetization of a ferromagnetic layer, enabling magnetization switching or precession. Key parameters governing STT efficiency include current density, spin polarization ratio, magnetic damping constant, and layer thickness, which influence the critical current required for magnetization manipulation. Understanding these parameters allows you to optimize device performance in spintronic applications such as magnetic random-access memory (MRAM) and spin-torque oscillators.

Material Considerations in Spin Pumping and STT

Material considerations in spin pumping and spin transfer torque (STT) are critical for optimizing device efficiency and performance. Heavy metals like platinum and tantalum are widely used in spin pumping due to their strong spin-orbit coupling, which enhances spin current generation, while ferromagnetic materials such as cobalt and permalloy are preferred for STT because of their favorable magnetic properties and spin polarization. Interface quality and material thickness directly influence spin mixing conductance and spin torque efficiency, making precise engineering of multilayer stacks essential for advancing spintronic applications.

Comparative Analysis: Spin Pumping vs Spin Transfer Torque

Spin pumping generates spin currents by dynamic magnetization in ferromagnets, transferring angular momentum to adjacent nonmagnetic layers and enabling efficient spin injection without charge flow. Spin transfer torque directly manipulates magnetization states via spin-polarized charge currents, offering precise control for magnetic memory and oscillators. Your choice depends on application needs: spin pumping favors contactless spin injection, while spin transfer torque excels in active control of magnetic switching.

Applications in Magnetic Devices

Spin pumping enhances magnetic resonance by generating pure spin currents, making it ideal for high-efficiency spintronic sensors and magnonic devices. Spin transfer torque allows direct manipulation of magnetization states using spin-polarized currents, crucial for developing non-volatile magnetic random-access memory (MRAM) and spin-torque oscillators. Your choice between these mechanisms depends on whether efficient spin current generation or precise magnetization control is required in advanced magnetic device applications.

Challenges and Future Perspectives

Challenges in spin pumping involve interfacial spin transparency and material conductivity mismatches that limit efficient spin current generation, while spin transfer torque faces issues with switching current density and device scalability. Future perspectives point toward engineering novel heterostructures with enhanced spin-mixing conductance and exploring low-damping magnetic materials to optimize energy efficiency. Your ability to integrate these advances could lead to breakthroughs in spintronic memory and logic devices with faster operation and reduced power consumption.

Conclusion and Outlook

Spin pumping efficiently generates pure spin currents by dynamic magnetization in ferromagnetic materials, while spin transfer torque directly manipulates magnetization using spin-polarized currents, enabling advanced control in spintronic devices. Future developments are expected to optimize these mechanisms for ultrafast, low-power memory and logic applications, leveraging materials with strong spin-orbit coupling and novel heterostructures. Understanding the interplay between spin pumping and spin transfer torque will enhance your ability to design next-generation spintronic technologies with improved energy efficiency and scalability.

spin pumping vs spin transfer torque Infographic

electrown.com

electrown.com