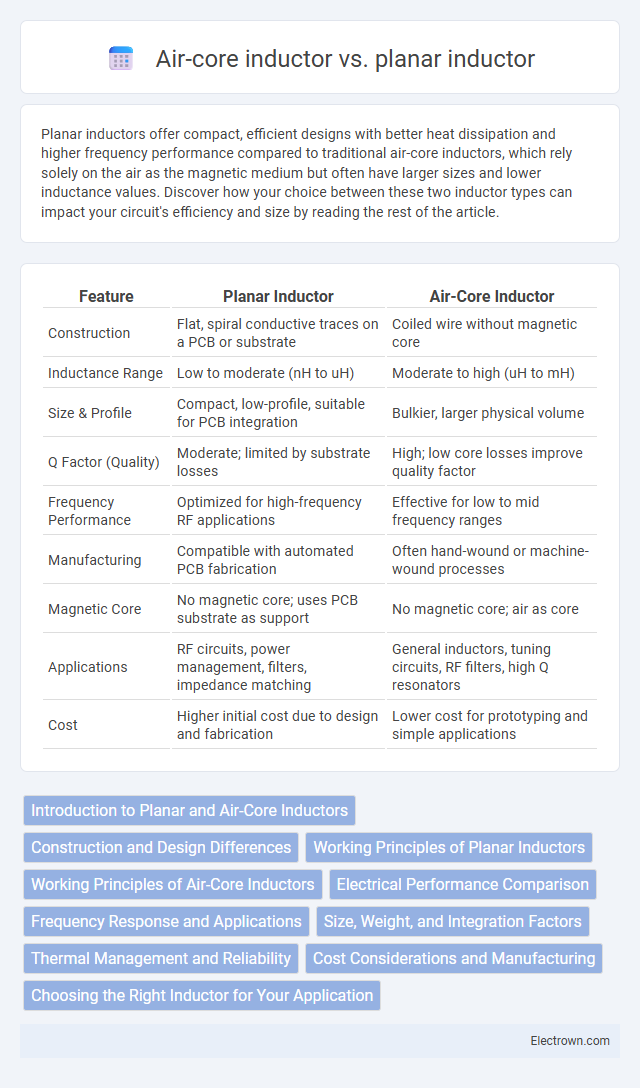

Planar inductors offer compact, efficient designs with better heat dissipation and higher frequency performance compared to traditional air-core inductors, which rely solely on the air as the magnetic medium but often have larger sizes and lower inductance values. Discover how your choice between these two inductor types can impact your circuit's efficiency and size by reading the rest of the article.

Table of Comparison

| Feature | Planar Inductor | Air-Core Inductor |

|---|---|---|

| Construction | Flat, spiral conductive traces on a PCB or substrate | Coiled wire without magnetic core |

| Inductance Range | Low to moderate (nH to uH) | Moderate to high (uH to mH) |

| Size & Profile | Compact, low-profile, suitable for PCB integration | Bulkier, larger physical volume |

| Q Factor (Quality) | Moderate; limited by substrate losses | High; low core losses improve quality factor |

| Frequency Performance | Optimized for high-frequency RF applications | Effective for low to mid frequency ranges |

| Manufacturing | Compatible with automated PCB fabrication | Often hand-wound or machine-wound processes |

| Magnetic Core | No magnetic core; uses PCB substrate as support | No magnetic core; air as core |

| Applications | RF circuits, power management, filters, impedance matching | General inductors, tuning circuits, RF filters, high Q resonators |

| Cost | Higher initial cost due to design and fabrication | Lower cost for prototyping and simple applications |

Introduction to Planar and Air-Core Inductors

Planar inductors consist of flat, spiral windings fabricated on a printed circuit board, offering compact size and improved heat dissipation for high-frequency applications. Air-core inductors use coils wound around a non-magnetic core, minimizing core losses and enabling linear inductance but often resulting in larger physical sizes. Both types serve critical roles in RF circuits and power electronics, with design choices driven by performance requirements such as inductance range, quality factor, and thermal management.

Construction and Design Differences

Planar inductors feature flat, spiral copper traces on a PCB, enabling compact and low-profile designs ideal for surface mounting. Air-core inductors consist of wire coils wound around a non-magnetic form, offering high-frequency performance without core losses but often resulting in larger, bulkier components. Your choice between these depends on space constraints and frequency requirements, balancing size, efficiency, and manufacturing complexity.

Working Principles of Planar Inductors

Planar inductors operate by using a flat, spiral-shaped conductor embedded in a printed circuit board to create a magnetic field when current flows through the coil, enabling efficient inductance in a compact form factor. Unlike traditional air-core inductors, planar inductors leverage the geometric configuration of the conductive layers and substrate materials to optimize magnetic flux distribution and minimize parasitic effects. This design allows planar inductors to deliver high Q-factors and stable inductance values at high frequencies, making them ideal for RF and power electronics applications.

Working Principles of Air-Core Inductors

Air-core inductors operate by generating a magnetic field around a coil of wire without a ferromagnetic core, relying solely on the permeability of air to store magnetic energy. Their working principle centers on inductance created by the coil's geometry and turns, which influences impedance and frequency response in high-frequency circuits. Unlike planar inductors that integrate coils on a substrate, air-core inductors minimize core losses and magnetic saturation, making them ideal for RF applications requiring low distortion and high Q-factors.

Electrical Performance Comparison

Planar inductors offer higher Q factors and better high-frequency performance due to their low parasitic capacitance and tightly controlled geometries compared to air-core inductors. Air-core inductors provide linear inductance with minimal core losses, making them ideal for applications requiring low distortion and stable inductance over temperature. Your choice between these depends on the frequency range and power levels, with planar inductors excelling in compact, high-frequency circuits while air-core inductors suit broad bandwidth, low-loss needs.

Frequency Response and Applications

Planar inductors exhibit superior high-frequency performance due to their low parasitic capacitance and precise geometric design, making them ideal for RF circuits and high-speed signal applications. Air-core inductors, with minimal core losses, provide better linearity and stability at a broad frequency range but are bulkier and less suitable for compact, high-frequency designs. Choosing between planar and air-core inductors depends on your application's frequency requirements and size constraints, with planar inductors favored for integrated and miniaturized high-frequency systems.

Size, Weight, and Integration Factors

Planar inductors offer a compact size and lower profile compared to traditional air-core inductors, making them ideal for space-constrained applications. Their lightweight design results from the integrated coil structure etched on a PCB, enabling better thermal management and ease of integration into multilayer circuit boards. Your choice between planar and air-core inductors depends on the importance of minimizing size and achieving seamless integration within modern electronic devices.

Thermal Management and Reliability

Planar inductors exhibit superior thermal management due to their flat, distributed winding structure, which enhances heat dissipation and reduces hot spots compared to air-core inductors. The use of PCB-integrated copper traces in planar inductors allows for efficient heat spreading, improving reliability under high-current or high-frequency conditions. Air-core inductors, lacking a magnetic core and often featuring wire-wound coils, face greater challenges in heat dissipation, leading to higher thermal stress and potential performance degradation over time.

Cost Considerations and Manufacturing

Planar inductors typically incur higher initial costs due to complex fabrication involving PCB layering and precise patterning, whereas air-core inductors are generally cheaper to produce with simpler winding techniques around non-magnetic forms. Manufacturing planar inductors demands advanced equipment and tight control over etching and lamination processes, leading to increased labor and setup expenses compared to the relatively straightforward coil winding of air-core inductors. When balancing cost considerations for your application, air-core inductors offer budget-friendly scalability, while planar inductors provide compactness and integration benefits often justifying their higher production investment.

Choosing the Right Inductor for Your Application

Planar inductors offer compact size, improved thermal management, and high-frequency performance, making them ideal for modern power electronics and space-constrained applications. Air-core inductors provide low core losses and linear inductance characteristics, suitable for high-frequency circuits where magnetic saturation must be avoided. Evaluating factors like operating frequency, thermal requirements, size constraints, and efficiency will help you choose the right inductor for your specific application.

Planar inductor vs air-core inductor Infographic

electrown.com

electrown.com