Cavity filters offer superior selectivity and higher power handling for RF signals, making them ideal for professional communication systems, whereas ceramic filters provide compact size and cost-effectiveness suitable for consumer electronics. Explore the detailed comparison to understand which filter best suits your specific application needs.

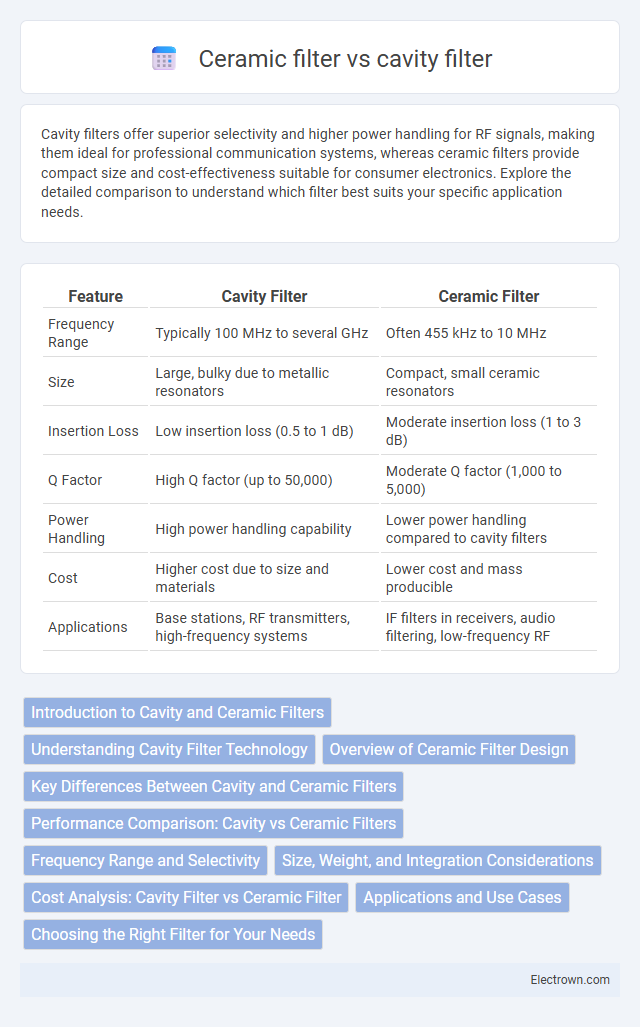

Table of Comparison

| Feature | Cavity Filter | Ceramic Filter |

|---|---|---|

| Frequency Range | Typically 100 MHz to several GHz | Often 455 kHz to 10 MHz |

| Size | Large, bulky due to metallic resonators | Compact, small ceramic resonators |

| Insertion Loss | Low insertion loss (0.5 to 1 dB) | Moderate insertion loss (1 to 3 dB) |

| Q Factor | High Q factor (up to 50,000) | Moderate Q factor (1,000 to 5,000) |

| Power Handling | High power handling capability | Lower power handling compared to cavity filters |

| Cost | Higher cost due to size and materials | Lower cost and mass producible |

| Applications | Base stations, RF transmitters, high-frequency systems | IF filters in receivers, audio filtering, low-frequency RF |

Introduction to Cavity and Ceramic Filters

Cavity filters use hollow metal chambers to selectively block or pass specific radio frequencies, excelling in high-power and narrow bandwidth applications common in RF communication systems. Ceramic filters employ piezoelectric ceramics to achieve compact size and high stability, often favored in low-power, compact devices like mobile phones and GPS receivers. Your choice between cavity and ceramic filters depends on factors such as frequency range, insertion loss, and application environment.

Understanding Cavity Filter Technology

Cavity filters utilize resonant cavities to achieve precise frequency selection with low insertion loss and high power handling, making them ideal for RF and microwave applications. In contrast, ceramic filters rely on piezoelectric ceramic materials to filter frequencies, offering compact size and cost-effectiveness but typically lower power tolerance. Your choice between cavity and ceramic filters depends on the required frequency accuracy, power level, and application environment.

Overview of Ceramic Filter Design

Ceramic filters utilize a piezoelectric ceramic resonator to achieve high selectivity and stability in frequency filtering, making them ideal for applications requiring precise signal processing. These filters typically feature compact, rugged construction with low insertion loss and sharp cutoff characteristics, enhancing your device's performance in RF communication systems. Compared to cavity filters, ceramic filters offer smaller size and cost advantages while maintaining effective filtering in narrow bandwidths.

Key Differences Between Cavity and Ceramic Filters

Cavity filters utilize hollow metal resonators to achieve high Q factors and narrow bandwidth suitable for high-frequency RF applications, whereas ceramic filters employ piezoelectric ceramic materials for compact size and stable frequency response at intermediate frequencies. Cavity filters offer superior power handling and lower insertion loss, making them ideal for base station and radar systems, while ceramic filters are preferred in consumer electronics due to cost-effectiveness and ease of integration. The primary distinction lies in their construction and operational frequency ranges, with cavity filters excelling in microwave bands and ceramic filters dominating audio and IF signal filtering.

Performance Comparison: Cavity vs Ceramic Filters

Cavity filters provide superior Q factor and insertion loss performance compared to ceramic filters, making them ideal for high-frequency applications requiring sharp selectivity and low signal attenuation. Ceramic filters, while more compact and cost-effective, typically exhibit lower Q values and wider bandwidths, resulting in reduced selectivity and higher insertion loss. The choice between cavity and ceramic filters depends on the application's requirements for size, cost, and filtering precision, with cavity filters favored in military and aerospace sectors for their high performance.

Frequency Range and Selectivity

Cavity filters offer a wider frequency range, typically from hundreds of MHz to several GHz, making them ideal for high-frequency applications, while ceramic filters excel in narrowband frequency ranges around a few MHz to a few hundred MHz. Cavity filters provide superior selectivity with sharper roll-off and lower insertion loss, enhancing signal clarity for complex communications systems. Your choice depends on the required frequency range and selectivity for optimal performance in RF filtering applications.

Size, Weight, and Integration Considerations

Cavity filters, typically larger and heavier due to their metallic resonant chambers, require more space and robust mounting for integration in RF systems, making them less suitable for compact or weight-sensitive applications. Ceramic filters are notably smaller and lighter thanks to their dielectric material and miniaturized construction, facilitating easy integration into compact devices like smartphones and wireless modules. Size and weight differences significantly influence the choice between cavity and ceramic filters, with ceramic filters preferred for space-constrained designs and cavity filters favored when high power handling and selectivity are essential.

Cost Analysis: Cavity Filter vs Ceramic Filter

Cavity filters generally have higher manufacturing and material costs due to their precise machining and larger size, making them more expensive than ceramic filters. Ceramic filters offer a cost-effective alternative with compact design and mass production capabilities, leading to lower unit prices and reduced assembly time. When evaluating total cost of ownership, factors like durability, insertion loss, and application-specific performance must also be considered alongside upfront expenses.

Applications and Use Cases

Cavity filters are commonly used in high-frequency communication systems like base stations and radar due to their high power handling and low insertion loss. Ceramic filters excel in compact devices such as mobile phones and Wi-Fi routers because of their small size and excellent frequency stability. Your choice depends on whether the application demands robustness and power capacity or miniaturization and precision.

Choosing the Right Filter for Your Needs

Cavity filters offer high Q-factor and superior selectivity for narrowband applications, making them ideal for wireless communication systems requiring minimal signal loss. Ceramic filters provide compact size and cost-effective performance, suitable for consumer electronics and moderate filtering needs. Assess your frequency range, bandwidth requirements, and physical constraints to choose the filter that best fits your application's demands.

Cavity filter vs ceramic filter Infographic

electrown.com

electrown.com