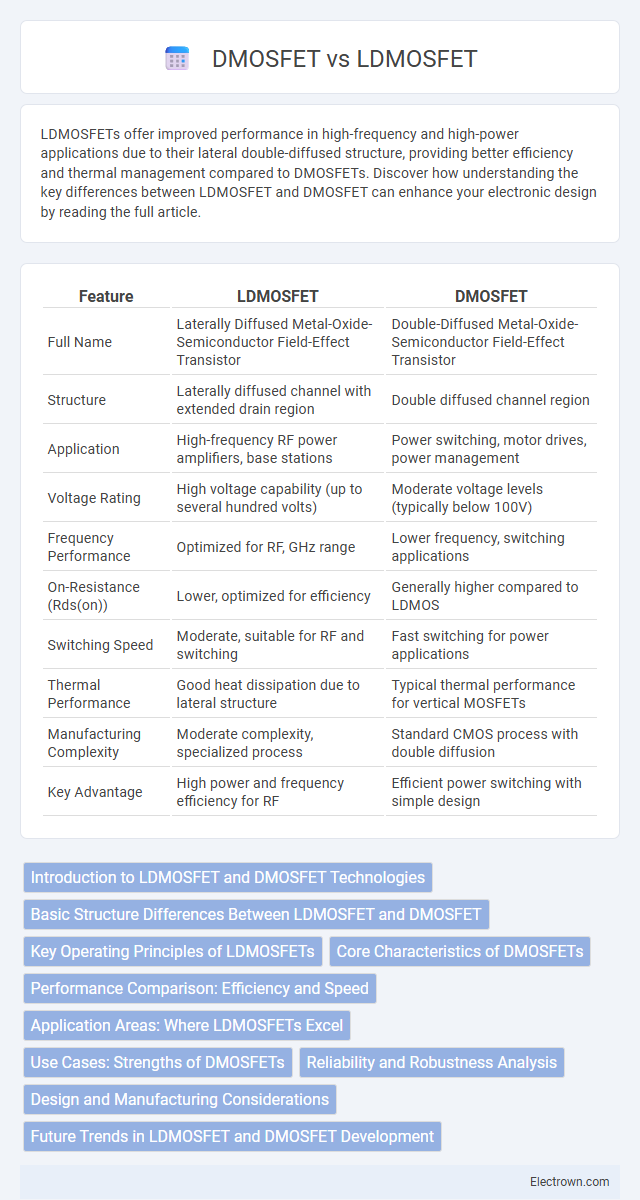

LDMOSFETs offer improved performance in high-frequency and high-power applications due to their lateral double-diffused structure, providing better efficiency and thermal management compared to DMOSFETs. Discover how understanding the key differences between LDMOSFET and DMOSFET can enhance your electronic design by reading the full article.

Table of Comparison

| Feature | LDMOSFET | DMOSFET |

|---|---|---|

| Full Name | Laterally Diffused Metal-Oxide-Semiconductor Field-Effect Transistor | Double-Diffused Metal-Oxide-Semiconductor Field-Effect Transistor |

| Structure | Laterally diffused channel with extended drain region | Double diffused channel region |

| Application | High-frequency RF power amplifiers, base stations | Power switching, motor drives, power management |

| Voltage Rating | High voltage capability (up to several hundred volts) | Moderate voltage levels (typically below 100V) |

| Frequency Performance | Optimized for RF, GHz range | Lower frequency, switching applications |

| On-Resistance (Rds(on)) | Lower, optimized for efficiency | Generally higher compared to LDMOS |

| Switching Speed | Moderate, suitable for RF and switching | Fast switching for power applications |

| Thermal Performance | Good heat dissipation due to lateral structure | Typical thermal performance for vertical MOSFETs |

| Manufacturing Complexity | Moderate complexity, specialized process | Standard CMOS process with double diffusion |

| Key Advantage | High power and frequency efficiency for RF | Efficient power switching with simple design |

Introduction to LDMOSFET and DMOSFET Technologies

LDMOSFET (Laterally Diffused Metal-Oxide-Semiconductor Field-Effect Transistor) and DMOSFET (Double-Diffused Metal-Oxide-Semiconductor Field-Effect Transistor) are advanced semiconductor devices commonly used in power amplification and switching applications. LDMOSFET technology is optimized for high-frequency and high-power scenarios, featuring a lateral diffusion process that enhances breakdown voltage and efficiency, making it ideal for RF power amplifiers. DMOSFETs employ a double diffusion process to form the channel, providing good switching performance and robust current handling, often utilized in low to medium power applications.

Basic Structure Differences Between LDMOSFET and DMOSFET

LDMOSFET features a laterally extended drift region compared to the vertical structure of the DMOSFET, enabling it to efficiently handle high voltages with reduced on-resistance. The DMOSFET typically employs a vertical double-diffused channel forming the main conduction path, while LDMOSFET integrates a lateral channel optimized for RF and power applications. Your choice between these devices should consider the structural impact on breakdown voltage, switching speed, and on-resistance for optimal performance.

Key Operating Principles of LDMOSFETs

LDMOSFETs (Laterally Diffused Metal-Oxide-Semiconductor Field-Effect Transistors) operate by utilizing a lateral diffusion process to create a drift region that enhances voltage handling capabilities compared to traditional DMOSFETs. The key operating principle involves controlling the current flow through a high-resistivity drift region, which allows LDMOSFETs to achieve superior breakdown voltage and efficiency in high-frequency power amplification applications. This lateral structure optimizes electric field distribution, reducing on-resistance and improving thermal performance critical for RF and microwave power devices.

Core Characteristics of DMOSFETs

DMOSFETs feature a double-diffused structure enabling high current density and low on-resistance, which improves efficiency in power switching applications. These devices exhibit excellent ruggedness and thermal stability due to their robust silicon construction and optimized channel formation. LDMOSFETs extend DMOSFET characteristics by including a lateral drift region that allows higher voltage operation and better RF performance, ideal for high-frequency power amplifiers.

Performance Comparison: Efficiency and Speed

LDMOSFETs offer higher power efficiency and improved thermal performance compared to traditional DMOSFETs due to their lateral double-diffused structure, which reduces on-resistance and gate charge. Your circuits benefit from LDMOSFETs' faster switching speeds, making them ideal for RF and power amplification applications. While DMOSFETs provide robust performance, LDMOSFETs excel in efficiency and speed, optimizing both energy consumption and operational frequency.

Application Areas: Where LDMOSFETs Excel

LDMOSFETs excel in high-power RF amplification applications, particularly in base station transmitters for wireless communication due to their superior efficiency and linearity at high frequencies. Their design supports high-voltage operation and excellent thermal performance, making them ideal for industrial and telecom power amplifiers. You benefit from enhanced signal strength and reduced distortion in demanding environments with LDMOSFET technology.

Use Cases: Strengths of DMOSFETs

DMOSFETs excel in high-frequency power amplification and switching applications due to their low on-resistance and fast switching speeds. These transistors are widely used in RF amplifiers, motor drives, and power management circuits where efficiency and thermal performance are critical. Their robust structure allows better handling of high voltage and current, making them ideal for automotive and industrial electronic systems.

Reliability and Robustness Analysis

LDMOSFETs exhibit superior reliability and robustness compared to traditional DMOSFETs due to their advanced lateral double-diffused structure, which enhances thermal management and electric field distribution. The reduced on-resistance and higher breakdown voltage in LDMOSFETs minimize hot spots and device degradation, making them ideal for high-power and high-frequency applications. When choosing your transistor for demanding environments, LDMOSFETs provide prolonged operational life and consistent performance under stress conditions.

Design and Manufacturing Considerations

LDMOSFETs feature a laterally diffused structure that enhances breakdown voltage and reduces on-resistance, demanding precise ion implantation and careful control of doping profiles during manufacturing. DMOSFETs typically have a simpler vertical or lateral design but may suffer from lower voltage tolerance compared to LDMOSFETs, making them easier to produce but less optimized for high-power applications. Your choice between LDMOSFET and DMOSFET depends on the specific design requirements, including efficiency, voltage capacity, and fabrication complexity.

Future Trends in LDMOSFET and DMOSFET Development

Future trends in LDMOSFET and DMOSFET development emphasize enhancing power efficiency and frequency performance for 5G and beyond communication systems. Researchers focus on scaling device structures and integrating advanced materials like GaN to reduce on-resistance and improve thermal management. Your choice between LDMOSFET and DMOSFET will increasingly depend on targeted applications requiring higher switching speeds and robust power handling capabilities.

LDMOSFET vs DMOSFET Infographic

electrown.com

electrown.com