Deep trench isolation (DTI) offers superior electrical isolation by creating deep, narrow trenches filled with insulating material to minimize substrate coupling and leakage, making it ideal for high-performance integrated circuits. Understanding the differences between DTI and Local Oxidation Isolation (LOCOS) can help you determine the best isolation technique for your semiconductor design--read on to explore their advantages and applications in detail.

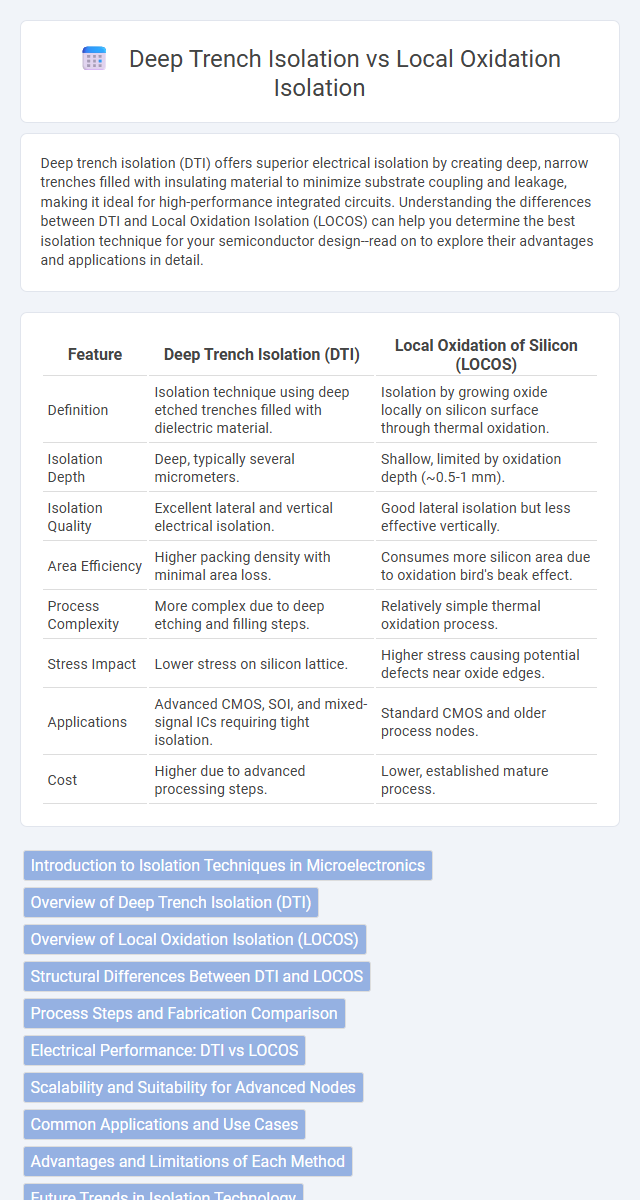

Table of Comparison

| Feature | Deep Trench Isolation (DTI) | Local Oxidation of Silicon (LOCOS) |

|---|---|---|

| Definition | Isolation technique using deep etched trenches filled with dielectric material. | Isolation by growing oxide locally on silicon surface through thermal oxidation. |

| Isolation Depth | Deep, typically several micrometers. | Shallow, limited by oxidation depth (~0.5-1 mm). |

| Isolation Quality | Excellent lateral and vertical electrical isolation. | Good lateral isolation but less effective vertically. |

| Area Efficiency | Higher packing density with minimal area loss. | Consumes more silicon area due to oxidation bird's beak effect. |

| Process Complexity | More complex due to deep etching and filling steps. | Relatively simple thermal oxidation process. |

| Stress Impact | Lower stress on silicon lattice. | Higher stress causing potential defects near oxide edges. |

| Applications | Advanced CMOS, SOI, and mixed-signal ICs requiring tight isolation. | Standard CMOS and older process nodes. |

| Cost | Higher due to advanced processing steps. | Lower, established mature process. |

Introduction to Isolation Techniques in Microelectronics

Deep trench isolation (DTI) and local oxidation of silicon (LOCOS) are critical isolation techniques in microelectronics for minimizing electrical crosstalk between adjacent devices on a semiconductor chip. DTI employs etched deep trenches filled with dielectric materials to provide superior isolation crucial for high-density and high-performance integrated circuits. LOCOS uses silicon dioxide grown locally through thermal oxidation to isolate devices, favored for its simplicity but often limited by lateral encroachment and scalability challenges.

Overview of Deep Trench Isolation (DTI)

Deep Trench Isolation (DTI) is a semiconductor fabrication technique that involves etching deep, narrow trenches into the silicon substrate and filling them with an insulating material such as silicon dioxide to electrically isolate devices. This method offers superior isolation compared to Local Oxidation of Silicon (LOCOS) by minimizing parasitic capacitance and leakage currents, which enhances device performance and scalability in high-density integrated circuits. DTI is particularly effective in advanced CMOS technologies where precise isolation is critical for reducing crosstalk and improving overall circuit reliability.

Overview of Local Oxidation Isolation (LOCOS)

Local Oxidation Isolation (LOCOS) is a semiconductor fabrication technique used to electrically isolate devices on a silicon wafer by growing a thick field oxide region through thermal oxidation, which prevents current leakage between adjacent components. Compared to Deep Trench Isolation (DTI), LOCOS forms isolation regions via the formation of silicon dioxide layers grown locally through a patterned oxide mask, leading to lateral oxide encroachment known as bird's beak effects that may reduce active area density. Despite its simplicity and cost-effectiveness, LOCOS is limited by scalability challenges in advanced technology nodes, making DTI preferable for high-density integration with minimal parasitic capacitance.

Structural Differences Between DTI and LOCOS

Deep trench isolation (DTI) features narrow, deep trenches etched into the silicon substrate filled with dielectric materials, providing high-density and effective isolation for advanced semiconductor devices. In contrast, Local Oxidation of Silicon (LOCOS) involves the formation of silicon dioxide regions through selective oxidation, creating thicker and less dense isolation areas with bird's beak structures that limit scaling. The structural differences directly impact device performance, with DTI enabling better packing density and reduced parasitic capacitance compared to the larger footprint and stress effects associated with LOCOS.

Process Steps and Fabrication Comparison

Deep trench isolation (DTI) involves etching deep trenches into the silicon substrate followed by filling them with dielectric materials, typically silicon oxide, to electrically isolate device regions. Local oxidation of silicon (LOCOS) involves growing a thick silicon dioxide layer via thermal oxidation to isolate transistors, using a nitride mask to define active areas. Your choice between DTI and LOCOS affects process complexity, with DTI offering superior isolation and packing density at the cost of more advanced etching and filling steps, while LOCOS provides simpler fabrication but suffers from lateral oxide encroachment, limiting scaling.

Electrical Performance: DTI vs LOCOS

Deep Trench Isolation (DTI) significantly reduces parasitic capacitance and leakage currents compared to Local Oxidation of Silicon (LOCOS), enhancing overall device speed and power efficiency. DTI provides superior isolation by creating deep oxide-filled trenches that effectively suppress substrate noise and latch-up, whereas LOCOS suffers from bird's beak effects leading to limited isolation scalability. Electrical performance metrics indicate that DTI enables higher transistor density and better frequency response, making it preferable for advanced CMOS technologies.

Scalability and Suitability for Advanced Nodes

Deep trench isolation (DTI) offers superior scalability for advanced semiconductor nodes due to its ability to create high aspect ratio trenches that effectively minimize parasitic capacitance and leakage currents. Local oxidation of silicon (LOCOS) isolation faces challenges with scaling as its lateral oxidation encroachment limits device density and performance at smaller geometries. Your choice for next-generation processes should consider DTI's enhanced suitability for ultra-scaled technology nodes, where precise isolation and reduced device interaction are critical.

Common Applications and Use Cases

Deep trench isolation (DTI) is commonly used in high-performance CMOS devices and image sensors to reduce crosstalk and improve device density by providing superior electrical isolation. Local oxidation of silicon (LOCOS) is typically applied in analog and mixed-signal integrated circuits where simpler, cost-effective isolation is sufficient, despite its larger lateral diffusion compared to DTI. Your choice between DTI and LOCOS will depend on the application's need for isolation precision, device scaling, and manufacturing complexity.

Advantages and Limitations of Each Method

Deep trench isolation offers superior electrical isolation and reduced parasitic capacitance, making it ideal for high-density integrated circuits and advanced CMOS technologies. Local oxidation isolation provides simpler processing with cost-effective fabrication, but it suffers from limited isolation depth and increased susceptibility to stress-induced defects. You should choose deep trench isolation for enhanced device performance, while local oxidation isolation remains suitable for less demanding applications with lower manufacturing complexity.

Future Trends in Isolation Technology

Future trends in isolation technology emphasize the shift towards deep trench isolation (DTI) due to its superior scalability and reduced parasitic capacitance, which supports advanced semiconductor nodes below 5 nm. As device geometries shrink, local oxidation isolation (LOCOS) faces limitations such as bird's beak encroachment and non-uniform oxide growth, making DTI more favorable for high-density integration and enhanced device performance. Emerging materials and process innovations aim to further improve DTI effectiveness by minimizing leakage currents and stress-induced defects, crucial for next-generation CMOS and 3D IC architectures.

Deep trench isolation vs Local oxidation isolation Infographic

electrown.com

electrown.com