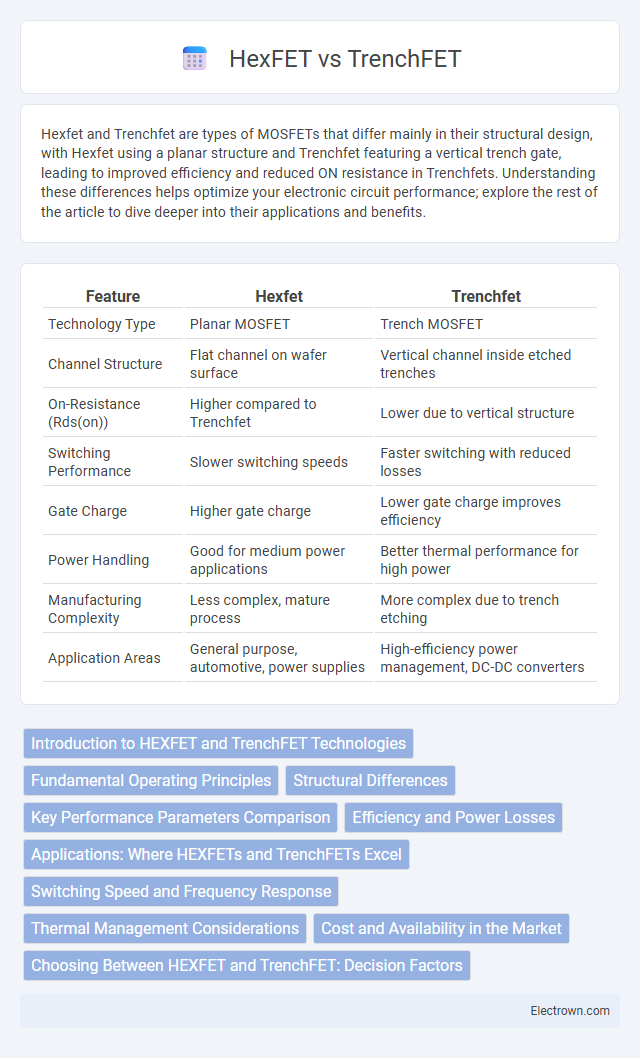

Hexfet and Trenchfet are types of MOSFETs that differ mainly in their structural design, with Hexfet using a planar structure and Trenchfet featuring a vertical trench gate, leading to improved efficiency and reduced ON resistance in Trenchfets. Understanding these differences helps optimize your electronic circuit performance; explore the rest of the article to dive deeper into their applications and benefits.

Table of Comparison

| Feature | Hexfet | Trenchfet |

|---|---|---|

| Technology Type | Planar MOSFET | Trench MOSFET |

| Channel Structure | Flat channel on wafer surface | Vertical channel inside etched trenches |

| On-Resistance (Rds(on)) | Higher compared to Trenchfet | Lower due to vertical structure |

| Switching Performance | Slower switching speeds | Faster switching with reduced losses |

| Gate Charge | Higher gate charge | Lower gate charge improves efficiency |

| Power Handling | Good for medium power applications | Better thermal performance for high power |

| Manufacturing Complexity | Less complex, mature process | More complex due to trench etching |

| Application Areas | General purpose, automotive, power supplies | High-efficiency power management, DC-DC converters |

Introduction to HEXFET and TrenchFET Technologies

HEXFET technology uses planar MOSFET structures with optimized cell patterns to deliver low on-resistance and fast switching for power applications. TrenchFET technology employs vertical trench gate MOSFET designs that enhance channel density and reduce gate charge, improving efficiency and thermal performance. Both technologies target improved power conversion but differ in their cell architecture and fabrication methods, influencing device characteristics like conduction losses and switching speeds.

Fundamental Operating Principles

Hexfet and Trenchfet MOSFETs differ fundamentally in their channel structures, impacting efficiency and switching performance. Hexfet devices utilize a planar gate structure with vertical channels, allowing for lower on-resistance and improved heat dissipation in power applications. Trenchfet MOSFETs employ a trench gate design that increases channel density and reduces gate charge, resulting in faster switching speeds and enhanced energy efficiency.

Structural Differences

Hexfet transistors feature a planar structure with vertical current flow, providing robust performance for power applications. Trenchfet technology employs a trench gate design that enhances channel density and reduces on-resistance by allowing a more efficient current path. This structural difference enables Trenchfet devices to achieve superior switching speed and thermal performance compared to traditional Hexfet devices.

Key Performance Parameters Comparison

Hexfet and Trenchfet technologies differ significantly in key performance parameters such as on-resistance, switching speed, and efficiency. Trenchfet MOSFETs typically offer lower on-resistance and higher current density due to their vertical channel structure, enhancing efficiency in high-power applications. Hexfet MOSFETs, known for their planar design, generally provide robust thermal performance and reliability, making them suitable for high-frequency switching environments.

Efficiency and Power Losses

Hexfet and Trenchfet both optimize efficiency in power electronics, but Trenchfet technology typically offers lower on-resistance (R_DS(on)), leading to reduced conduction losses compared to Hexfet designs. Trenchfets enhance switching efficiency by minimizing gate charge, which decreases switching losses and overall power dissipation. Consequently, Trenchfets provide improved energy efficiency and thermal performance in high-frequency and high-current applications relative to traditional Hexfet MOSFETs.

Applications: Where HEXFETs and TrenchFETs Excel

HEXFETs excel in high-voltage applications such as power supplies, motor drives, and automotive electronics due to their rugged construction and efficient heat dissipation. TrenchFETs dominate in low-voltage, high-frequency switching environments like computer power management and DC-DC converters, offering lower on-resistance and faster switching speeds. The choice between HEXFET and TrenchFET hinges on the operating voltage, switching frequency, and thermal management requirements of the application.

Switching Speed and Frequency Response

HexFET technology offers faster switching speeds due to its planar structure, which reduces parasitic capacitances and allows efficient operation at higher frequencies. TrenchFET devices provide improved frequency response with lower R_DS(on) and enhanced channel density, making them ideal for high-frequency switching applications. Your choice between HexFET and TrenchFET depends on balancing switching speed and frequency requirements for optimal power efficiency.

Thermal Management Considerations

HexFET technology offers robust thermal management due to its planar structure, enabling efficient heat dissipation across the flat silicon surface. TrenchFETs feature a vertically etched channel design that reduces on-resistance but can concentrate heat in smaller areas, requiring careful thermal analysis to avoid hotspots. Understanding these differences allows you to optimize thermal performance in power electronics and maintain device reliability.

Cost and Availability in the Market

Hexfet transistors generally offer lower cost and more widespread availability due to their longer presence in the market and established manufacturing processes. Trenchfet technology, while providing improved efficiency and performance, often comes at a higher price point and may have limited stock depending on specific applications. Your choice depends on balancing budget constraints with desired device efficiency and accessibility.

Choosing Between HEXFET and TrenchFET: Decision Factors

Choosing between HEXFET and TrenchFET involves evaluating power efficiency, switching speed, and thermal performance. HEXFET devices offer robust reliability and lower conduction losses in high-voltage applications, while TrenchFETs excel in low-voltage scenarios with reduced gate charge and faster switching capabilities. Key decision factors include device RDS(on), gate charge, operating voltage, and application-specific efficiency requirements.

Hexfet vs Trenchfet Infographic

electrown.com

electrown.com