LDMOS transistors offer higher power efficiency and better thermal performance compared to VDMOS, making them ideal for RF amplification and high-frequency applications. Explore the rest of the article to understand which technology best suits your specific electronic design needs.

Table of Comparison

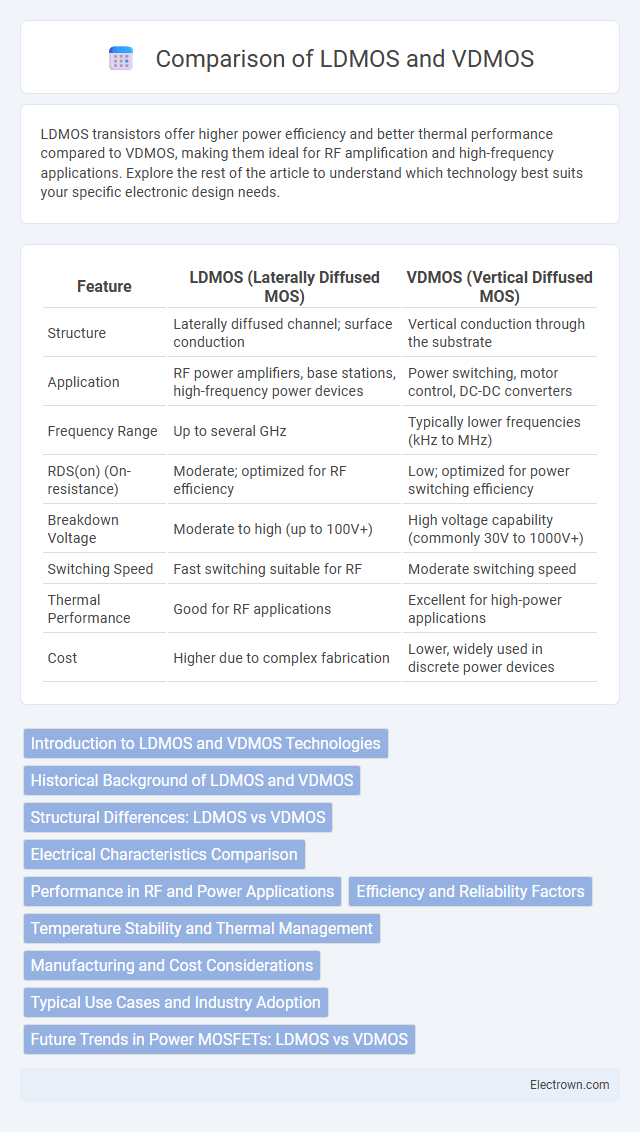

| Feature | LDMOS (Laterally Diffused MOS) | VDMOS (Vertical Diffused MOS) |

|---|---|---|

| Structure | Laterally diffused channel; surface conduction | Vertical conduction through the substrate |

| Application | RF power amplifiers, base stations, high-frequency power devices | Power switching, motor control, DC-DC converters |

| Frequency Range | Up to several GHz | Typically lower frequencies (kHz to MHz) |

| RDS(on) (On-resistance) | Moderate; optimized for RF efficiency | Low; optimized for power switching efficiency |

| Breakdown Voltage | Moderate to high (up to 100V+) | High voltage capability (commonly 30V to 1000V+) |

| Switching Speed | Fast switching suitable for RF | Moderate switching speed |

| Thermal Performance | Good for RF applications | Excellent for high-power applications |

| Cost | Higher due to complex fabrication | Lower, widely used in discrete power devices |

Introduction to LDMOS and VDMOS Technologies

LDMOS (Laterally Diffused Metal-Oxide-Semiconductor) and VDMOS (Vertical Diffused Metal-Oxide-Semiconductor) are key transistor technologies commonly used in power amplification and switching applications. LDMOS devices offer high efficiency and linearity, making them ideal for RF power amplifiers, while VDMOS transistors provide high current density and low on-resistance suited for power conversion and motor control. Understanding the structural differences of lateral diffusion in LDMOS and vertical diffusion in VDMOS is essential for selecting the right technology for Your high-performance electronic circuits.

Historical Background of LDMOS and VDMOS

LDMOS (Laterally Diffused Metal Oxide Semiconductor) technology emerged in the 1980s as a breakthrough for high-power RF amplifiers, offering enhanced efficiency and ruggedness compared to earlier devices. VDMOS (Vertical Diffused Metal Oxide Semiconductor) was developed earlier in the 1970s, targeting power switching applications with its vertical current flow design, enabling low on-resistance and high voltage handling. The evolution of LDMOS built upon the vertical conduction principles of VDMOS but introduced a lateral structure that improved performance in high-frequency and RF power applications.

Structural Differences: LDMOS vs VDMOS

LDMOS features a laterally diffused structure that enhances breakdown voltage and reduces on-resistance, making it ideal for high-power RF applications. VDMOS utilizes a vertical structure allowing for higher current densities and better heat dissipation, which suits power switching uses. Your choice between LDMOS and VDMOS depends on the specific demands for voltage handling and efficiency in your design.

Electrical Characteristics Comparison

LDMOS transistors exhibit higher breakdown voltage and improved ruggedness compared to VDMOS, making them ideal for high-power RF applications. VDMOS devices typically offer lower on-resistance and faster switching speeds, beneficial in low-voltage, high-efficiency DC-DC converters. Your choice depends on balancing voltage handling needs versus switching performance and conduction losses.

Performance in RF and Power Applications

LDMOS transistors exhibit superior performance in RF and power applications due to their higher breakdown voltage, better thermal stability, and excellent linearity compared to VDMOS devices. Their ability to handle high power levels and efficient power gain makes LDMOS the preferred choice in base station amplifiers and high-frequency power amplifiers. VDMOS transistors, while cost-effective and suitable for low-voltage switching, generally offer lower efficiency and linearity in high-frequency power applications.

Efficiency and Reliability Factors

LDMOS transistors typically offer higher efficiency due to their superior electron mobility and reduced on-resistance compared to VDMOS devices, making them ideal for high-frequency RF power applications. The lateral structure of LDMOS contributes to better thermal management and enhanced reliability under high voltage stress, whereas VDMOS devices may suffer from greater leakage currents and higher susceptibility to avalanche breakdown. Your choice between LDMOS and VDMOS should consider these efficiency and reliability factors to optimize performance in power amplification or switching applications.

Temperature Stability and Thermal Management

LDMOS transistors exhibit superior temperature stability compared to VDMOS due to their lateral structure, which enhances heat dissipation and reduces thermal resistance. Effective thermal management in LDMOS devices allows higher power handling at elevated temperatures, maintaining performance and reliability. VDMOS, with its vertical architecture, faces greater challenges in heat removal, leading to potential thermal runaway under high power conditions.

Manufacturing and Cost Considerations

LDMOS transistors typically require more complex manufacturing processes due to their advanced lateral doping profiles and thicker drift regions, leading to higher production costs compared to VDMOS devices. VDMOS devices benefit from simpler vertical structures and well-established fabrication techniques, making them more cost-effective for high-volume production. When selecting between LDMOS and VDMOS for your project, consider the trade-offs in cost efficiency and process complexity associated with each technology.

Typical Use Cases and Industry Adoption

LDMOS transistors are commonly used in RF power amplifiers for base stations, broadcast transmitters, and radar systems due to their high efficiency and linearity at high frequencies. VDMOS devices find widespread application in automotive electronics, power management, and low-voltage switching circuits where fast switching and low on-resistance are critical. The telecommunications and aerospace industries predominantly adopt LDMOS technology, while consumer electronics and industrial automation sectors rely heavily on VDMOS solutions.

Future Trends in Power MOSFETs: LDMOS vs VDMOS

Future trends in power MOSFETs highlight the growing preference for LDMOS technology due to its superior high-frequency performance, robustness, and efficiency in RF power amplifiers. VDMOS remains relevant for low-voltage, high-current applications but faces challenges in scalability and breakdown voltage compared to LDMOS. Innovations in LDMOS fabrication, such as enhanced trench structures and optimized drift regions, are driving improved power density and thermal management, positioning LDMOS as the dominant choice in advanced power electronics.

LDMOS vs VDMOS Infographic

electrown.com

electrown.com