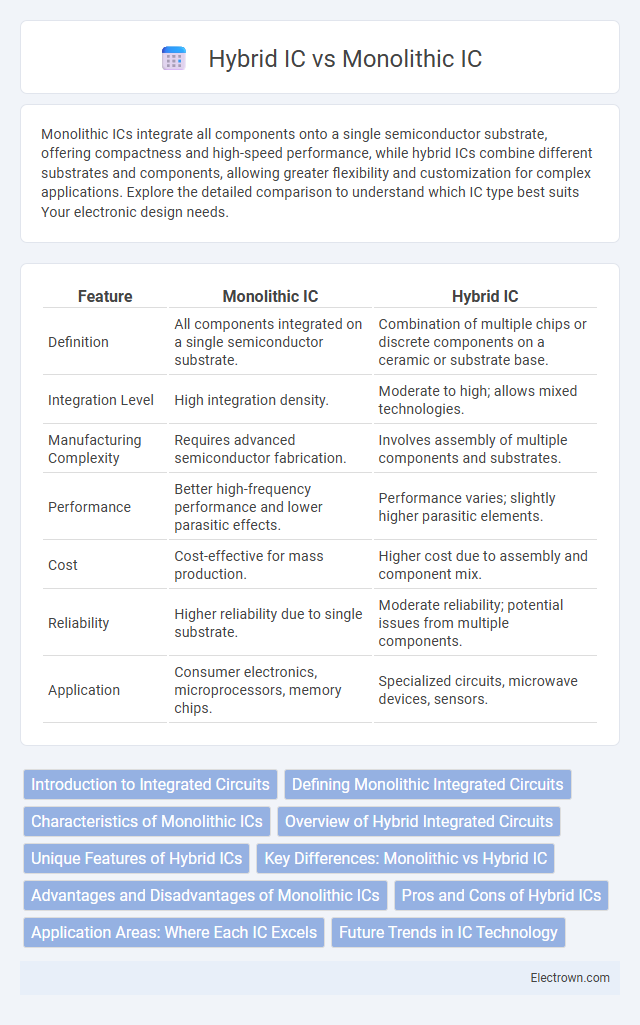

Monolithic ICs integrate all components onto a single semiconductor substrate, offering compactness and high-speed performance, while hybrid ICs combine different substrates and components, allowing greater flexibility and customization for complex applications. Explore the detailed comparison to understand which IC type best suits Your electronic design needs.

Table of Comparison

| Feature | Monolithic IC | Hybrid IC |

|---|---|---|

| Definition | All components integrated on a single semiconductor substrate. | Combination of multiple chips or discrete components on a ceramic or substrate base. |

| Integration Level | High integration density. | Moderate to high; allows mixed technologies. |

| Manufacturing Complexity | Requires advanced semiconductor fabrication. | Involves assembly of multiple components and substrates. |

| Performance | Better high-frequency performance and lower parasitic effects. | Performance varies; slightly higher parasitic elements. |

| Cost | Cost-effective for mass production. | Higher cost due to assembly and component mix. |

| Reliability | Higher reliability due to single substrate. | Moderate reliability; potential issues from multiple components. |

| Application | Consumer electronics, microprocessors, memory chips. | Specialized circuits, microwave devices, sensors. |

Introduction to Integrated Circuits

Integrated circuits (ICs) are miniature electronic devices that integrate numerous components like transistors, resistors, and capacitors onto a single semiconductor substrate. Monolithic ICs are built entirely on one silicon chip, offering compact size and improved performance, while hybrid ICs combine multiple discrete components and substrates, allowing greater design flexibility and customization. Understanding the differences in fabrication and application between monolithic and hybrid ICs can help you select the most suitable solution for your electronic design needs.

Defining Monolithic Integrated Circuits

Monolithic Integrated Circuits (ICs) consist of multiple electronic components fabricated on a single semiconductor substrate, typically silicon, enabling compact size and improved performance. These circuits integrate transistors, resistors, capacitors, and other elements directly into one chip, reducing parasitic effects and manufacturing complexity. Understanding Monolithic ICs helps you evaluate their advantages over hybrid ICs in terms of scalability, reliability, and cost-effectiveness.

Characteristics of Monolithic ICs

Monolithic ICs integrate all components on a single semiconductor substrate, offering high reliability and compact size with fast signal processing capabilities. They exhibit lower parasitic capacitance and resistance, ensuring improved electrical performance and reduced noise compared to hybrid ICs. Their manufacturing process enables mass production with consistent performance and cost efficiency.

Overview of Hybrid Integrated Circuits

Hybrid Integrated Circuits (HICs) combine multiple discrete semiconductor devices and passive components on a ceramic or organic substrate, offering enhanced flexibility and customized performance compared to monolithic ICs. HICs enable integration of varied technologies such as bipolar, CMOS, and GaAs components, suitable for high-frequency and high-power applications in aerospace, military, and telecommunications. The use of thick-film or thin-film fabrication techniques in HICs allows for improved thermal management and higher reliability in harsh environments.

Unique Features of Hybrid ICs

Hybrid ICs combine multiple semiconductor devices and passive components on a single substrate, offering unmatched design flexibility compared to monolithic ICs. The integration of thick-film or thin-film components allows hybrid ICs to achieve higher power handling, better thermal management, and improved frequency response. Their unique ability to customize component types and values directly on the substrate makes them ideal for specialized applications requiring robust performance and miniaturization.

Key Differences: Monolithic vs Hybrid IC

Monolithic ICs integrate all components and circuits on a single semiconductor substrate, resulting in compact size, lower cost, and higher reliability due to fewer interconnections. Hybrid ICs combine different components such as semiconductors, resistors, and capacitors on a ceramic or metal substrate using various packaging techniques, allowing greater design flexibility and enhanced performance for high-frequency or power applications. Key differences include manufacturing complexity, cost-efficiency, environmental stability, and application suitability, with monolithic ICs excelling in mass production and hybrid ICs preferred for specialized, high-performance circuits.

Advantages and Disadvantages of Monolithic ICs

Monolithic ICs offer advantages such as high reliability, compact size, and lower manufacturing costs due to integration on a single semiconductor substrate, enhancing performance through reduced parasitic elements and faster operation speeds. Their disadvantages include limited flexibility for complex circuit functions and difficulty in integrating varied materials or technologies, making them less suitable for custom or highly specialized applications. Monolithic ICs also face challenges in thermal management and scalability when compared to hybrid ICs, which can combine different substrates and components more easily.

Pros and Cons of Hybrid ICs

Hybrid ICs offer high reliability and flexibility by combining different semiconductor technologies into a single package, making them ideal for complex or high-performance applications. Their ability to use discrete components alongside integrated circuits results in better thermal management and customization but often leads to higher production costs and larger physical size compared to monolithic ICs. You should consider these trade-offs when selecting hybrid ICs for specialized electronic designs requiring optimized performance and endurance.

Application Areas: Where Each IC Excels

Monolithic ICs excel in high-frequency and low-noise applications such as RF amplifiers, sensors, and high-speed digital circuits due to their compact size and superior parasitic control. Hybrid ICs are preferred in power electronics, microwave circuits, and applications requiring heterogeneous material integration because they allow combining different substrates and discrete components for enhanced performance and thermal management. Both IC types are pivotal in aerospace, medical devices, and communication systems, with monolithic ICs dominating miniaturized, integrated solutions and hybrid ICs providing robustness and flexibility in complex, high-power environments.

Future Trends in IC Technology

Monolithic ICs continue to advance with silicon-based materials pushing the limits of miniaturization and integration density, enabling faster processing speeds and lower power consumption. Hybrid IC technology evolves by incorporating heterogeneous materials and 3D stacking techniques, offering enhanced performance for specialized applications such as RF and high-frequency circuits. Your choice between monolithic and hybrid ICs will depend on future demands for scalability, cost efficiency, and multifunctional integration in next-generation electronic devices.

Monolithic vs hybrid IC Infographic

electrown.com

electrown.com