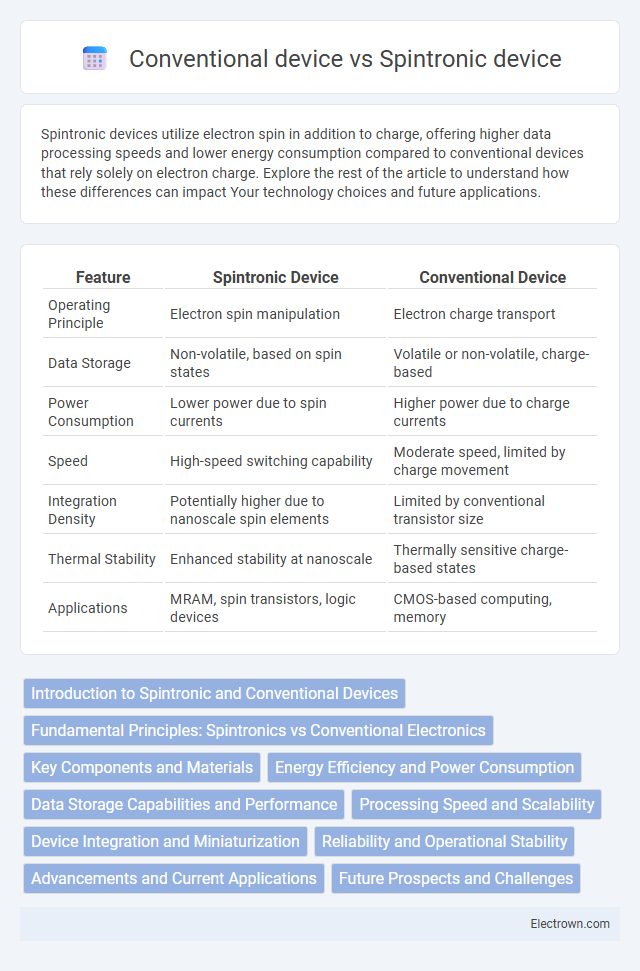

Spintronic devices utilize electron spin in addition to charge, offering higher data processing speeds and lower energy consumption compared to conventional devices that rely solely on electron charge. Explore the rest of the article to understand how these differences can impact Your technology choices and future applications.

Table of Comparison

| Feature | Spintronic Device | Conventional Device |

|---|---|---|

| Operating Principle | Electron spin manipulation | Electron charge transport |

| Data Storage | Non-volatile, based on spin states | Volatile or non-volatile, charge-based |

| Power Consumption | Lower power due to spin currents | Higher power due to charge currents |

| Speed | High-speed switching capability | Moderate speed, limited by charge movement |

| Integration Density | Potentially higher due to nanoscale spin elements | Limited by conventional transistor size |

| Thermal Stability | Enhanced stability at nanoscale | Thermally sensitive charge-based states |

| Applications | MRAM, spin transistors, logic devices | CMOS-based computing, memory |

Introduction to Spintronic and Conventional Devices

Spintronic devices exploit the intrinsic spin of electrons alongside their charge to enhance data processing and storage capabilities, offering advantages such as non-volatility, faster operation, and reduced power consumption. Conventional devices, primarily based on charge transport in semiconductors like silicon, rely on electron flow without leveraging spin properties, limiting their performance and energy efficiency. The integration of spintronic technologies in next-generation electronics aims to overcome the fundamental limitations of traditional charge-based devices.

Fundamental Principles: Spintronics vs Conventional Electronics

Spintronic devices operate based on the intrinsic spin of electrons and their associated magnetic moment, leveraging spin states to encode information, whereas conventional electronic devices rely solely on the charge of electrons for signal processing. The manipulation of spin currents in spintronics allows for non-volatile memory and reduced power consumption, contrasting with charge-based current flow in traditional semiconductors. This fundamental difference enables spintronic devices to offer enhanced data processing speed, increased storage density, and improved energy efficiency compared to conventional electronics.

Key Components and Materials

Spintronic devices primarily rely on magnetic materials such as ferromagnetic metals, magnetic tunnel junctions (MTJs), and spin valves to manipulate electron spin, whereas conventional devices depend on semiconductor materials like silicon for charge-based operations. Key components in spintronic devices include spin injectors, detectors, and non-magnetic spacers that facilitate spin transport and control, contrasting with the transistor-centric architecture of conventional devices. The use of materials with high spin polarization and long spin coherence lengths, such as cobalt, iron, and nickel alloys, distinguishes spintronic technology from traditional electronics focused on charge carrier mobility and bandgap engineering.

Energy Efficiency and Power Consumption

Spintronic devices typically exhibit higher energy efficiency and lower power consumption compared to conventional electronic devices due to their ability to manipulate electron spin rather than charge, which reduces resistive losses. These devices enable faster switching speeds and non-volatile memory operation, significantly lowering energy usage in computing and data storage applications. Your technology solutions can benefit from the enhanced energy-saving potential of spintronics in reducing overall system power demands.

Data Storage Capabilities and Performance

Spintronic devices leverage electron spin alongside charge, enabling significantly higher data storage density and faster read/write speeds compared to conventional electronic devices that rely solely on charge. Your data storage capabilities are enhanced by non-volatile memory features in spintronic devices, which maintain information without power while providing lower energy consumption and longer device lifetimes. Performance improvements include ultrafast switching speeds and enhanced durability, positioning spintronic technology as a superior choice for next-generation memory and logic applications.

Processing Speed and Scalability

Spintronic devices leverage electron spin along with charge, enabling faster data processing speeds compared to conventional semiconductor devices that rely solely on charge. The inherent non-volatility and lower power consumption of spintronic components enhance scalability in high-density memory and logic applications. Advances in materials like magnetic tunnel junctions and spin-transfer torque RAM demonstrate promising scalability potential beyond the limits of traditional CMOS technology.

Device Integration and Miniaturization

Spintronic devices leverage electron spin properties to achieve higher data density and reduced power consumption, enabling superior device integration and miniaturization compared to conventional charge-based devices. Their compatibility with existing semiconductor fabrication processes facilitates seamless integration into advanced circuits, making them ideal for scaling down device size without sacrificing performance. You can benefit from enhanced computational efficiency and smaller device footprints in applications ranging from memory storage to logic components.

Reliability and Operational Stability

Spintronic devices exhibit higher reliability and operational stability than conventional devices due to their inherent resistance to electromagnetic interference and lower heat generation. The use of electron spin rather than charge reduces wear and degradation, enabling longer device lifespans and consistent performance under varying environmental conditions. Studies show spintronic components maintain stable operation across billions of cycles, outperforming traditional semiconductor devices prone to thermal and electrical stress failures.

Advancements and Current Applications

Spintronic devices leverage electron spin along with charge, offering advancements in data storage density, energy efficiency, and operational speed compared to conventional electronic devices that rely solely on charge. Current applications of spintronics include magnetic random-access memory (MRAM), spin-transfer torque devices, and quantum computing components, providing non-volatile memory solutions and enhanced data processing capabilities. Your technology infrastructure can benefit from these innovations by adopting spintronic components for faster, more reliable, and energy-saving performance.

Future Prospects and Challenges

Spintronic devices offer promising future prospects due to their potential for higher data processing speeds, lower power consumption, and enhanced non-volatility compared to conventional electronic devices. Challenges include material fabrication complexities, device scalability, and integration with existing semiconductor technology, which require ongoing research and development. Your ability to leverage these advancements will depend on overcoming these obstacles to unlock the full potential of spintronics in next-generation computing and memory systems.

Spintronic device vs Conventional device Infographic

electrown.com

electrown.com