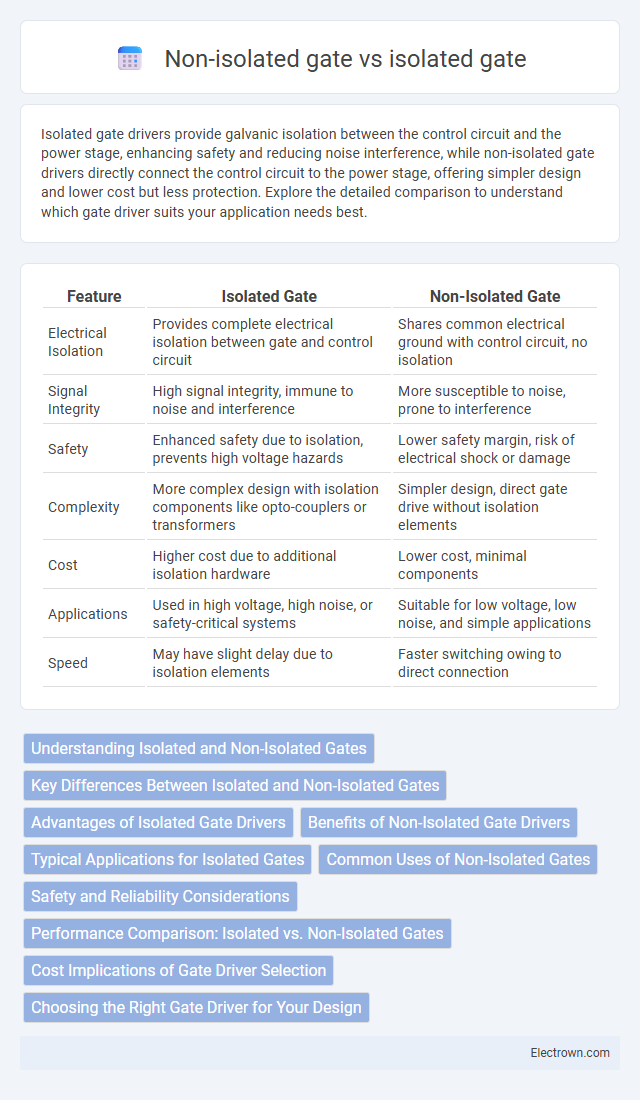

Isolated gate drivers provide galvanic isolation between the control circuit and the power stage, enhancing safety and reducing noise interference, while non-isolated gate drivers directly connect the control circuit to the power stage, offering simpler design and lower cost but less protection. Explore the detailed comparison to understand which gate driver suits your application needs best.

Table of Comparison

| Feature | Isolated Gate | Non-Isolated Gate |

|---|---|---|

| Electrical Isolation | Provides complete electrical isolation between gate and control circuit | Shares common electrical ground with control circuit, no isolation |

| Signal Integrity | High signal integrity, immune to noise and interference | More susceptible to noise, prone to interference |

| Safety | Enhanced safety due to isolation, prevents high voltage hazards | Lower safety margin, risk of electrical shock or damage |

| Complexity | More complex design with isolation components like opto-couplers or transformers | Simpler design, direct gate drive without isolation elements |

| Cost | Higher cost due to additional isolation hardware | Lower cost, minimal components |

| Applications | Used in high voltage, high noise, or safety-critical systems | Suitable for low voltage, low noise, and simple applications |

| Speed | May have slight delay due to isolation elements | Faster switching owing to direct connection |

Understanding Isolated and Non-Isolated Gates

Isolated gates provide galvanic isolation between the input control signal and the power device, essential for safety and noise reduction in high-voltage applications. Non-isolated gates directly connect the control circuit to the power switch, enabling faster switching speeds but requiring careful design to avoid ground loops and interference. Understanding the trade-offs between isolated and non-isolated gates is critical for optimizing efficiency, reliability, and electromagnetic compatibility in power electronics systems.

Key Differences Between Isolated and Non-Isolated Gates

Isolated gates in power electronics use galvanic isolation techniques such as optocouplers or transformers to electrically separate input and output signals, enhancing safety and noise immunity. Non-isolated gates lack this separation, resulting in direct electrical connection, which can simplify design but may increase susceptibility to noise and pose safety risks. Isolated gates are preferred in high-voltage applications, while non-isolated gates fit low-voltage or cost-sensitive designs.

Advantages of Isolated Gate Drivers

Isolated gate drivers provide galvanic isolation between the control and power circuits, enhancing safety and reducing electrical noise interference. They enable higher voltage operation and improve system reliability by preventing ground loop issues. These drivers are ideal for high-voltage applications, offering better protection for sensitive control electronics and ensuring accurate signal transmission.

Benefits of Non-Isolated Gate Drivers

Non-isolated gate drivers offer improved efficiency and cost-effectiveness by directly connecting the control and power circuits, reducing the need for additional isolation components. These drivers provide faster switching speeds and lower propagation delays, enhancing overall system performance in motor control and power conversion applications. Their simpler design also results in smaller board space, making them ideal for compact and high-density electronic devices.

Typical Applications for Isolated Gates

Isolated gate drivers are commonly used in high-voltage power conversion systems, such as motor drives, renewable energy inverters, and industrial automation, where electrical isolation between control and power circuits is critical for safety and noise immunity. They are essential in applications requiring galvanic isolation, including grid-tied solar inverters and electric vehicle powertrains, to prevent ground loops and protect low-voltage control electronics. These drivers also find typical use in isolated DC-DC converters and medical devices where strict isolation standards must be met.

Common Uses of Non-Isolated Gates

Non-isolated gates are commonly used in power conversion and motor control applications where direct electrical connection between the input and output is acceptable, such as DC-DC converters and synchronous rectifiers. They provide efficient switching with lower cost and simpler design compared to isolated gates, favoring embedded systems and battery-powered devices. Their widespread adoption in applications requiring high switching speeds and compact circuitry makes them ideal for integrated power management solutions.

Safety and Reliability Considerations

Isolated gate drivers provide galvanic isolation between control and power circuits, significantly enhancing safety by preventing high voltage from reaching the control side and reducing the risk of electric shock or equipment damage. Non-isolated gate drivers lack this isolation, making them more susceptible to noise and potential fault propagation, which can compromise system reliability in high-voltage applications. Selecting isolated gate drivers is critical for ensuring robust operation and long-term durability in environments where electrical isolation and protection against transient voltage spikes are required.

Performance Comparison: Isolated vs. Non-Isolated Gates

Isolated gate drivers offer superior noise immunity and enhanced safety by providing galvanic isolation between the control and power circuits, which improves overall system reliability. Non-isolated gate drivers typically deliver faster switching speeds and lower propagation delays, making them suitable for applications prioritizing high-speed performance and compact design. Your choice depends on whether isolation for protection or speed and integration is more critical in the application.

Cost Implications of Gate Driver Selection

Isolated gate drivers typically incur higher costs due to the need for additional components like transformers or optocouplers that provide galvanic isolation, enhancing safety and noise immunity. Non-isolated gate drivers are generally more cost-effective but may require careful PCB layout and filtering to manage noise, impacting your overall system reliability. Choosing between isolated and non-isolated gate drivers depends largely on your budget constraints and the electrical environment of your application.

Choosing the Right Gate Driver for Your Design

Choosing the right gate driver for your design depends on the specific isolation requirements and voltage levels in your application. Isolated gate drivers provide galvanic isolation, enhancing safety and noise immunity in high-voltage or sensitive circuits, while non-isolated gate drivers offer simpler, cost-effective solutions for low-voltage systems with common ground references. Evaluating your system's need for isolation, switching speed, and power efficiency will ensure you select the optimal driver that meets both performance and reliability criteria.

Isolated gate vs non-isolated gate Infographic

electrown.com

electrown.com