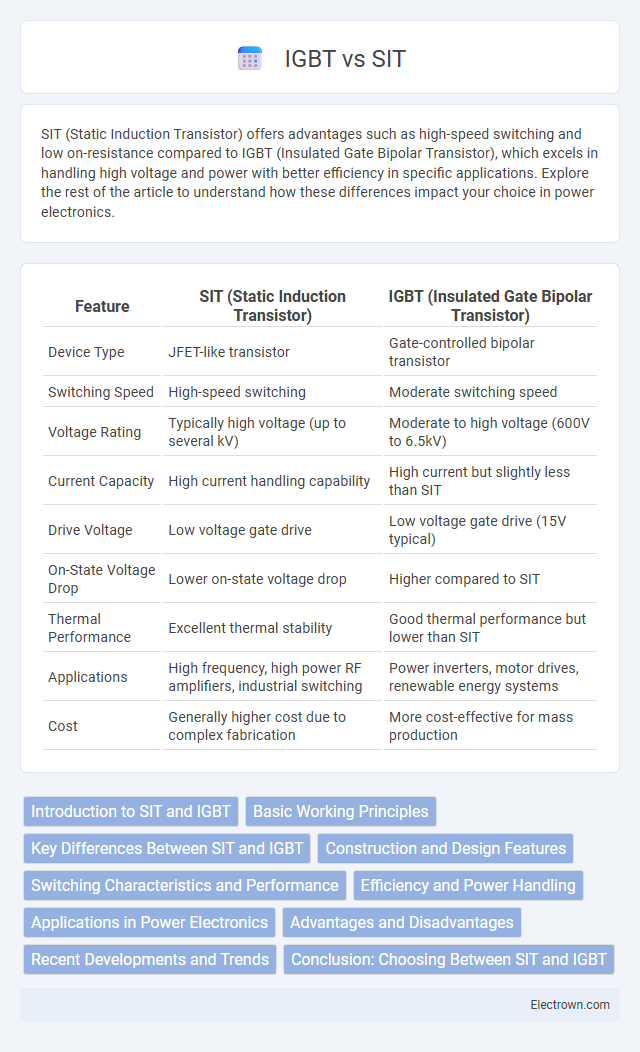

SIT (Static Induction Transistor) offers advantages such as high-speed switching and low on-resistance compared to IGBT (Insulated Gate Bipolar Transistor), which excels in handling high voltage and power with better efficiency in specific applications. Explore the rest of the article to understand how these differences impact your choice in power electronics.

Table of Comparison

| Feature | SIT (Static Induction Transistor) | IGBT (Insulated Gate Bipolar Transistor) |

|---|---|---|

| Device Type | JFET-like transistor | Gate-controlled bipolar transistor |

| Switching Speed | High-speed switching | Moderate switching speed |

| Voltage Rating | Typically high voltage (up to several kV) | Moderate to high voltage (600V to 6.5kV) |

| Current Capacity | High current handling capability | High current but slightly less than SIT |

| Drive Voltage | Low voltage gate drive | Low voltage gate drive (15V typical) |

| On-State Voltage Drop | Lower on-state voltage drop | Higher compared to SIT |

| Thermal Performance | Excellent thermal stability | Good thermal performance but lower than SIT |

| Applications | High frequency, high power RF amplifiers, industrial switching | Power inverters, motor drives, renewable energy systems |

| Cost | Generally higher cost due to complex fabrication | More cost-effective for mass production |

Introduction to SIT and IGBT

Silicon Insulated Gate Transistors (SITs) and Insulated Gate Bipolar Transistors (IGBTs) are semiconductor devices widely used in power electronics for switching and amplification. SITs are known for their high voltage capability and low on-state resistance, making them suitable for high-frequency applications and efficient power conversion. IGBTs combine the high input impedance and fast switching of MOSFETs with the high current and voltage handling of bipolar transistors, offering a balance ideal for medium to high power applications such as motor drives and inverters.

Basic Working Principles

SIT (Static Induction Transistor) operates by controlling current through a vertical channel with a gate region that modulates the flow of carriers, enabling high-speed switching and low conduction losses. IGBT (Insulated Gate Bipolar Transistor) combines MOSFET gate control with bipolar current conduction, allowing efficient handling of high voltages and currents. Understanding these basic working principles helps you select the appropriate device for power electronics applications requiring fast switching and high efficiency.

Key Differences Between SIT and IGBT

SIT (Static Induction Transistor) features low on-resistance and high-speed switching, making it ideal for high-frequency power applications, while IGBT (Insulated Gate Bipolar Transistor) combines high input impedance with bipolar conduction for efficient high-power switching. SIT typically operates with a unipolar conduction mechanism leading to lower switching losses, whereas IGBT employs bipolar conduction that enables higher current capacity but with comparatively higher switching losses. The key differences lie in their internal structures, switching speed, conduction mechanisms, and suitability for various power electronics tasks, with SIT favored in RF amplifiers and IGBT in motor drives and inverters.

Construction and Design Features

Silicon Injection Transistors (SITs) feature a vertical structure with low on-resistance and high current capacity, designed for efficient high-frequency switching. Insulated Gate Bipolar Transistors (IGBTs) combine the input characteristics of MOSFETs with the output performance of bipolar transistors, utilizing a gate oxide layer for high input impedance and a bipolar output stage for high voltage handling. Your choice depends on the specific construction benefits, with SITs excelling in rugged robustness and IGBTs offering superior versatility and thermal performance.

Switching Characteristics and Performance

SIT (Static Induction Transistor) exhibits faster switching speeds and lower on-resistance compared to IGBT (Insulated Gate Bipolar Transistor), enabling higher efficiency in high-frequency power applications. IGBTs offer robust performance at high voltages and currents, but their switching losses and slower turn-off times can limit performance in ultra-fast switching scenarios. SIT's superior switching characteristics make it suitable for applications requiring high-speed and low-loss operation, whereas IGBTs excel in medium-frequency, high-power environments.

Efficiency and Power Handling

SIT (Static Induction Transistor) delivers higher efficiency with lower conduction losses compared to IGBT (Insulated Gate Bipolar Transistor), making it ideal for high-frequency applications. SIT devices excel in power handling with superior current density and faster switching speeds, enabling improved thermal performance under heavy load. Your choice between SIT and IGBT depends on the balance between efficiency demands and power capacity requirements in your electronic system.

Applications in Power Electronics

SIT (Static Induction Transistor) offers high-speed switching and low on-resistance, making it suitable for high-frequency power converters and RF amplifiers. IGBTs (Insulated Gate Bipolar Transistors) excel in handling high voltage and current in industrial motor drives, renewable energy inverters, and traction systems. Both devices optimize efficiency in power electronics, with SITs favored for fast switching applications and IGBTs preferred for high-power, high-voltage scenarios.

Advantages and Disadvantages

Silicon carbide SITs (Static Induction Transistors) offer high-frequency operation and low on-resistance, making them efficient for power switching applications with minimal losses. IGBTs (Insulated Gate Bipolar Transistors) excel in handling high voltage and current but typically have slower switching speeds and higher conduction losses compared to SITs. Your choice depends on the application requirements, balancing SITs' superior switching efficiency against IGBTs' robustness for high power.

Recent Developments and Trends

Recent developments in Silicon Carbide (SIT) and Insulated Gate Bipolar Transistors (IGBT) highlight significant advancements in power semiconductor efficiency and thermal performance. SIT technology increasingly leverages wide bandgap materials, enabling higher switching speeds and reduced energy losses, which are critical for electric vehicle inverters and renewable energy systems. Concurrently, IGBT manufacturers focus on enhancing short-circuit robustness and lowering on-state voltage drop, driving trends towards compact, high-power density modules for industrial automation and smart grid applications.

Conclusion: Choosing Between SIT and IGBT

SIT (Static Induction Transistor) offers superior high-frequency performance and faster switching speeds, making it ideal for applications requiring low noise and high efficiency. IGBT (Insulated Gate Bipolar Transistor) excels in high voltage and high current operations, commonly used in power electronics and industrial drives due to its robustness and ease of control. Your choice between SIT and IGBT depends on the specific requirements of switching speed, voltage, current ratings, and thermal management in your application.

SIT vs IGBT Infographic

electrown.com

electrown.com