Planar transistors feature a flat structure where current flows horizontally across the semiconductor surface, offering simplicity and cost-effectiveness in manufacturing. Vertical transistors, on the other hand, channel current vertically through the device, enabling higher current density and improved performance in compact designs; explore the rest of the article to understand how each type can impact Your electronic projects.

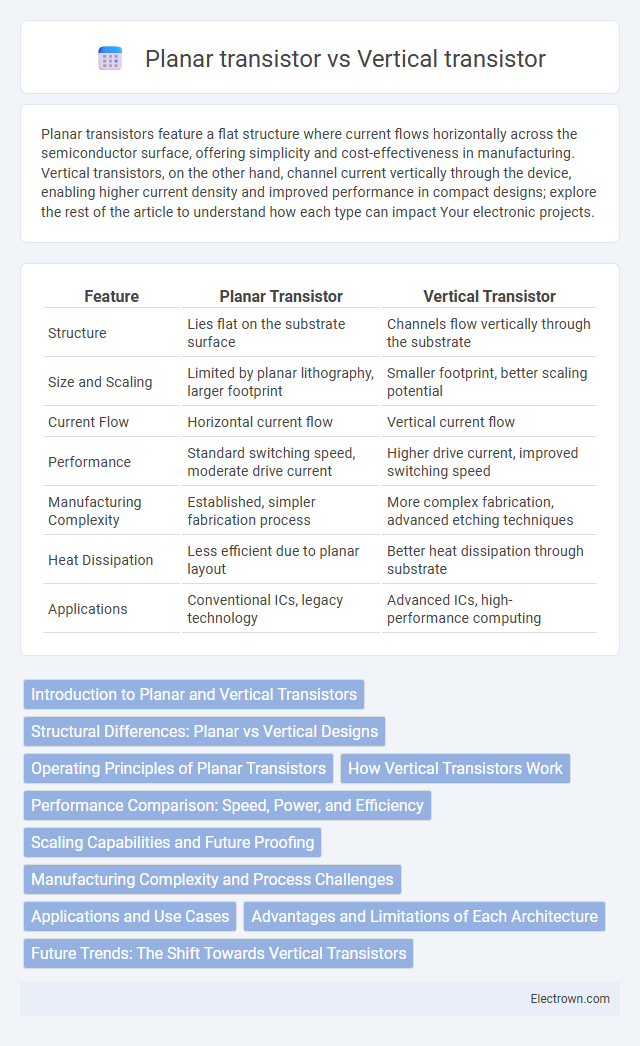

Table of Comparison

| Feature | Planar Transistor | Vertical Transistor |

|---|---|---|

| Structure | Lies flat on the substrate surface | Channels flow vertically through the substrate |

| Size and Scaling | Limited by planar lithography, larger footprint | Smaller footprint, better scaling potential |

| Current Flow | Horizontal current flow | Vertical current flow |

| Performance | Standard switching speed, moderate drive current | Higher drive current, improved switching speed |

| Manufacturing Complexity | Established, simpler fabrication process | More complex fabrication, advanced etching techniques |

| Heat Dissipation | Less efficient due to planar layout | Better heat dissipation through substrate |

| Applications | Conventional ICs, legacy technology | Advanced ICs, high-performance computing |

Introduction to Planar and Vertical Transistors

Planar transistors feature a flat, horizontal layout where current flows parallel to the substrate, making them ideal for traditional CMOS technology and scaling down in microelectronics. Vertical transistors, such as FinFETs, utilize a three-dimensional structure that allows current to flow vertically through the device, enhancing performance by increasing channel control and reducing leakage. Your choice between planar and vertical transistors impacts the balance of power efficiency, speed, and footprint in semiconductor device design.

Structural Differences: Planar vs Vertical Designs

Planar transistors feature a flat, two-dimensional structure where the current flows horizontally across the semiconductor surface, enabling straightforward fabrication and integration on traditional silicon wafers. Vertical transistors, however, utilize a three-dimensional design with current flowing vertically through the device, allowing for higher drive currents and improved scalability in smaller technology nodes. Your choice between planar and vertical designs significantly impacts device performance, density, and power efficiency in modern semiconductor applications.

Operating Principles of Planar Transistors

Planar transistors operate based on a horizontal arrangement where the current flows laterally across the semiconductor surface, controlled by a gate electrode positioned above the channel. The gate voltage modulates the conductivity of the channel by creating an electric field that influences electron movement within the planar layout. This structure enables precise control of charge carriers, making planar transistors fundamental in integrated circuit fabrication.

How Vertical Transistors Work

Vertical transistors operate by directing current flow vertically through the semiconductor substrate, allowing for greater transistor density and improved performance in integrated circuits compared to planar transistors. The vertical architecture reduces channel length and short-channel effects, enhancing switching speed and energy efficiency in devices like FinFETs and gate-all-around transistors. Understanding how your device's vertical transistor functions is crucial for optimizing power consumption and computational speed in advanced electronics.

Performance Comparison: Speed, Power, and Efficiency

Vertical transistors generally exhibit faster switching speeds and better power efficiency compared to planar transistors due to their shorter channel lengths and improved current flow paths. Your device performance benefits from reduced power consumption as vertical transistors minimize leakage currents and heat dissipation. Speed optimization in vertical transistors results from their three-dimensional structure, allowing higher drive current and improved scalability over traditional planar designs.

Scaling Capabilities and Future Proofing

Planar transistors face significant scaling challenges due to short-channel effects and leakage currents as technology nodes shrink below 10nm, limiting their future-proofing potential. Vertical transistors, such as 3D FinFETs and gate-all-around (GAA) architectures, offer superior electrostatic control and enable more aggressive scaling, improving device performance and power efficiency at nanoscale dimensions. Your choice of vertical transistor technology can provide better scalability and longevity in advanced semiconductor manufacturing processes.

Manufacturing Complexity and Process Challenges

Planar transistors feature a simpler manufacturing process with established lithography techniques, resulting in lower fabrication complexity and cost. Vertical transistors require advanced 3D structuring methods, such as deep etching and precise layer stacking, which increase process challenges and yield risks. Your choice between the two impacts production efficiency, where planar offers maturity and vertical provides enhanced scaling potential despite higher complexity.

Applications and Use Cases

Planar transistors dominate in general-purpose microprocessors and digital logic circuits due to their mature fabrication process and high switching speed. Vertical transistors, such as FinFETs, excel in low-power and high-performance applications like mobile processors and advanced semiconductor nodes because of their superior gate control and reduced leakage current. Your choice between planar and vertical transistors depends on the specific power efficiency, scaling, and performance requirements of your electronic device.

Advantages and Limitations of Each Architecture

Planar transistors offer simpler fabrication processes and mature technology with well-established manufacturing techniques, providing excellent control over channel length and low leakage currents. Vertical transistors enable higher device density and improved current drive by stacking channels vertically, optimizing space for advanced scaling, yet they face challenges in thermal management and increased complexity in fabrication. While planar designs dominate in cost-effective, low-power applications, vertical transistors excel in high-performance devices requiring superior electrostatic control and power efficiency but demand more sophisticated manufacturing infrastructure.

Future Trends: The Shift Towards Vertical Transistors

The semiconductor industry is rapidly shifting towards vertical transistors due to their superior scalability and enhanced performance at nanoscale dimensions compared to traditional planar transistors. Vertical transistors, such as gate-all-around (GAA) and FinFET designs, enable better control of channel electrostatics, reduced leakage current, and higher drive currents, making them essential for future high-speed and low-power applications. Your devices will benefit from this evolution as vertical transistor technology continues to dominate next-generation processors and memory chips, driving advancements in AI, 5G, and IoT systems.

Planar transistor vs Vertical transistor Infographic

electrown.com

electrown.com