Standard Operating Procedures (SOP) provide detailed, step-by-step instructions to ensure consistent workflow and compliance in various processes, while Quality Function Deployment (QFD) focuses on translating customer requirements into technical specifications to enhance product quality. Understanding the distinct roles of SOP and QFP can help you optimize operational efficiency and product development; explore the rest of the article to discover how each tool can benefit your organization.

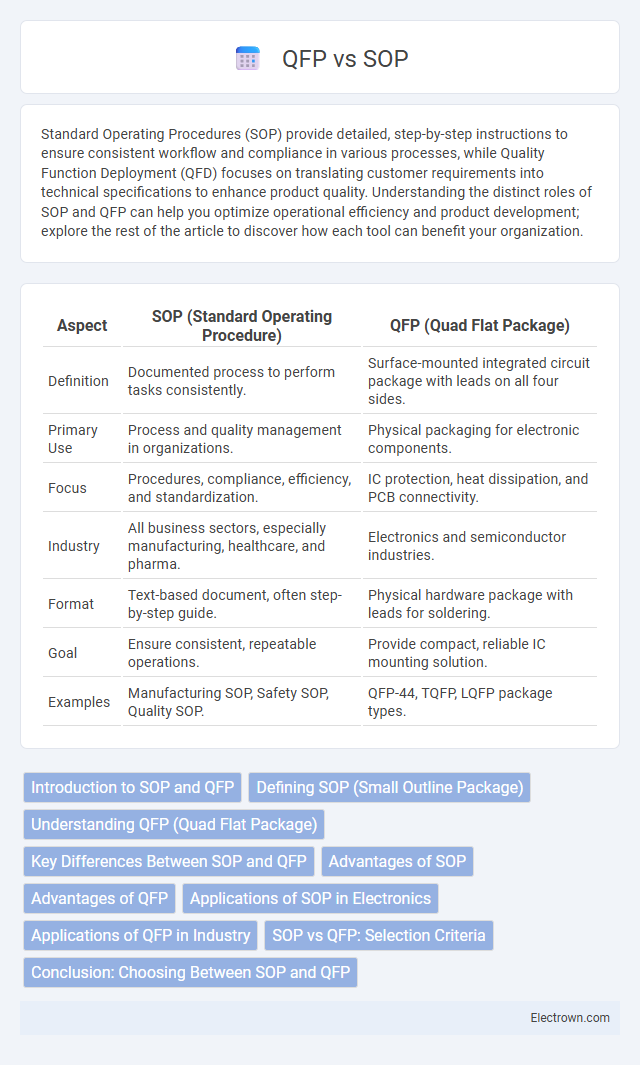

Table of Comparison

| Aspect | SOP (Standard Operating Procedure) | QFP (Quad Flat Package) |

|---|---|---|

| Definition | Documented process to perform tasks consistently. | Surface-mounted integrated circuit package with leads on all four sides. |

| Primary Use | Process and quality management in organizations. | Physical packaging for electronic components. |

| Focus | Procedures, compliance, efficiency, and standardization. | IC protection, heat dissipation, and PCB connectivity. |

| Industry | All business sectors, especially manufacturing, healthcare, and pharma. | Electronics and semiconductor industries. |

| Format | Text-based document, often step-by-step guide. | Physical hardware package with leads for soldering. |

| Goal | Ensure consistent, repeatable operations. | Provide compact, reliable IC mounting solution. |

| Examples | Manufacturing SOP, Safety SOP, Quality SOP. | QFP-44, TQFP, LQFP package types. |

Introduction to SOP and QFP

SOP (Small Outline Package) and QFP (Quad Flat Package) are common surface-mount IC packaging types used in electronics for efficient soldering and assembly. SOP features a rectangular body with gull-wing leads extending from two sides, making it ideal for compact designs with moderate pin counts. QFP has a square or rectangular shape with leads on all four sides, accommodating higher pin counts and offering increased connectivity for complex circuits.

Defining SOP (Small Outline Package)

Small Outline Package (SOP) is a surface-mount integrated circuit package characterized by a rectangular shape with gull-wing leads extending from the longer sides, designed for space-efficient PCB layouts and reliable soldering. SOPs are widely used in applications requiring moderate pin counts and excellent electrical performance, offering a balanced solution between size and thermal dissipation. You can optimize your circuit design by selecting SOP for components needing compact footprints without compromising connectivity and mechanical stability.

Understanding QFP (Quad Flat Package)

The Quad Flat Package (QFP) is a surface-mount integrated circuit package with leads extending from all four sides, designed for efficient heat dissipation and compact circuit board layouts. Unlike the Small Outline Package (SOP), QFP provides a higher pin count, making it suitable for complex applications requiring multiple connections. Understanding QFP helps you select appropriate packaging for high-density electronic designs, ensuring optimal performance and manufacturability.

Key Differences Between SOP and QFP

SOP (Small Outline Package) and QFP (Quad Flat Package) differ primarily in pin configuration and mounting style; SOP has pins on two sides, while QFP features pins on all four sides, enabling higher pin counts and complexity. SOP is generally used for medium to low pin counts and is more compact in size, making it suitable for space-constrained designs. Your choice depends on the required pin density and board layout, as QFP supports more connections but occupies more PCB area compared to SOP.

Advantages of SOP

Small Outline Package (SOP) offers advantages such as a smaller footprint compared to Quad Flat Package (QFP), allowing for higher circuit density on printed circuit boards (PCBs). SOP's lead spacing typically enables better electrical performance and reduced parasitic inductance, which is crucial for high-frequency applications. Its streamlined design facilitates easier automated assembly and inspection, improving manufacturing efficiency and yield.

Advantages of QFP

QFP (Quad Flat Package) offers superior advantages over SOP (Small Outline Package) such as higher pin density, making it ideal for complex integrated circuits requiring numerous connections. Its flat leads improve heat dissipation and facilitate automated surface-mount assembly, enhancing manufacturing efficiency and reliability. You benefit from improved signal integrity and space-saving design, essential for modern electronic devices.

Applications of SOP in Electronics

Small Outline Package (SOP) is widely used in electronics for surface-mounted integrated circuits due to its compact size and efficient heat dissipation. It is commonly applied in consumer electronics, automotive control systems, power management devices, and communication equipment. SOP's reliability and ease of automated assembly make it ideal for microcontrollers, memory chips, and analog devices, enhancing performance in complex electronic circuits.

Applications of QFP in Industry

QFP (Quad Flat Package) is widely used in consumer electronics, automotive control systems, and telecommunications due to its ability to handle high-density integrated circuits efficiently. This package type supports complex microcontrollers and processors, making it ideal for applications requiring reliable performance and compact design, such as smartphones, automotive ECUs, and network devices. Choosing QFP ensures your products benefit from cost-effective manufacturing and enhanced soldering stability in high-volume production environments.

SOP vs QFP: Selection Criteria

SOP (Small Outline Package) and QFP (Quad Flat Package) selection depends on factors like PCB space constraints, pin count, and thermal management. SOP suits applications requiring compact size and fewer pins, offering ease of soldering and cost-effectiveness. QFP is ideal for high-pin-count devices needing efficient heat dissipation and robust mechanical stability in complex circuits.

Conclusion: Choosing Between SOP and QFP

Choosing between SOP (Small Outline Package) and QFP (Quad Flat Package) depends on application requirements such as board space, pin count, and thermal performance. SOP offers a more compact footprint suitable for lower pin counts and simpler circuits, while QFP provides higher pin density, making it ideal for complex, multi-pin integrated circuits. Evaluating factors like manufacturability, cost, and electrical characteristics ensures the optimal package selection for specific electronic designs.

SOP vs QFP Infographic

electrown.com

electrown.com