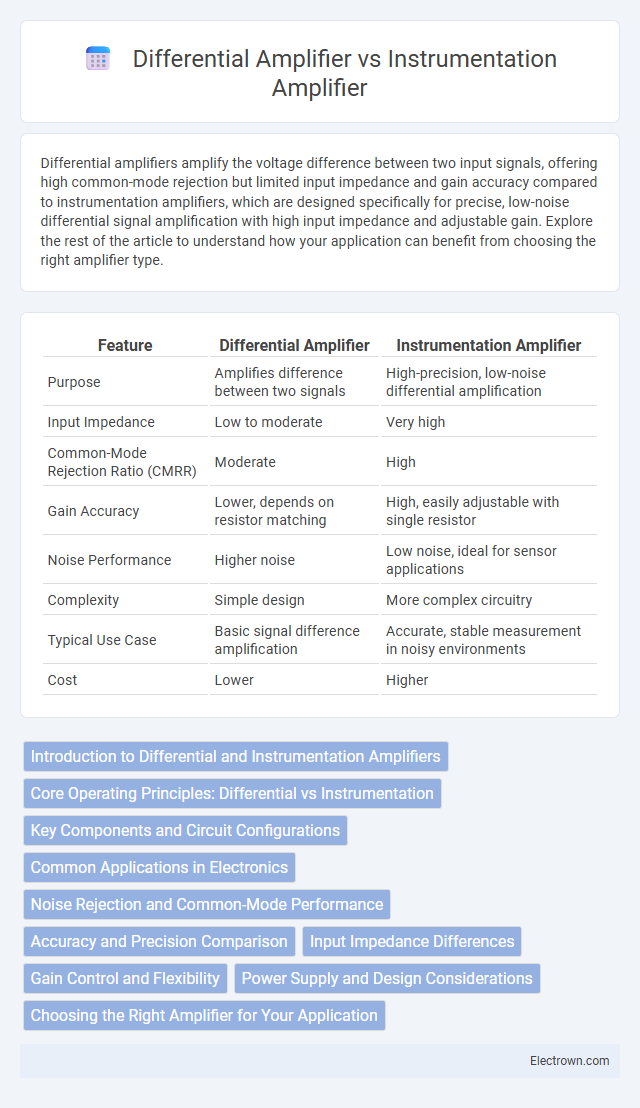

Differential amplifiers amplify the voltage difference between two input signals, offering high common-mode rejection but limited input impedance and gain accuracy compared to instrumentation amplifiers, which are designed specifically for precise, low-noise differential signal amplification with high input impedance and adjustable gain. Explore the rest of the article to understand how your application can benefit from choosing the right amplifier type.

Table of Comparison

| Feature | Differential Amplifier | Instrumentation Amplifier |

|---|---|---|

| Purpose | Amplifies difference between two signals | High-precision, low-noise differential amplification |

| Input Impedance | Low to moderate | Very high |

| Common-Mode Rejection Ratio (CMRR) | Moderate | High |

| Gain Accuracy | Lower, depends on resistor matching | High, easily adjustable with single resistor |

| Noise Performance | Higher noise | Low noise, ideal for sensor applications |

| Complexity | Simple design | More complex circuitry |

| Typical Use Case | Basic signal difference amplification | Accurate, stable measurement in noisy environments |

| Cost | Lower | Higher |

Introduction to Differential and Instrumentation Amplifiers

Differential amplifiers amplify the voltage difference between two input signals, providing essential noise rejection in various electronic applications. Instrumentation amplifiers build upon this principle by offering higher input impedance, precise gain accuracy, and enhanced common-mode rejection, making them ideal for sensitive measurement systems. Understanding the advantages of your specific circuit needs can guide you in choosing between a differential amplifier and an instrumentation amplifier for optimal performance.

Core Operating Principles: Differential vs Instrumentation

A differential amplifier amplifies the voltage difference between two input signals while rejecting any common-mode voltage, making it ideal for basic signal conditioning. An instrumentation amplifier builds on this principle by incorporating input buffer stages and precise gain control to achieve high input impedance and superior common-mode rejection ratio (CMRR), essential for accurate, low-noise measurements in sensitive applications. Your choice between the two depends on the required precision, input impedance, and noise performance for your specific signal acquisition task.

Key Components and Circuit Configurations

Differential amplifiers primarily consist of two input transistors or operational amplifiers configured to amplify the voltage difference between inputs, with resistors setting gain and common-mode rejection. Instrumentation amplifiers use three operational amplifiers: two as buffer amplifiers at the inputs and one differential amplifier stage, providing high input impedance, precise gain control through a single resistor, and enhanced noise rejection. Your choice depends on the need for accuracy and impedance matching, with instrumentation amplifiers excelling in precision sensor signal conditioning.

Common Applications in Electronics

Differential amplifiers are extensively used in audio systems, signal conditioning, and operational amplifier circuits where noise reduction and signal fidelity are critical. Instrumentation amplifiers are preferred in medical devices, industrial process controls, and sensor signal amplification due to their high input impedance, precise gain settings, and superior common-mode rejection ratio (CMRR). Both amplifier types play crucial roles in enhancing weak bio-signals like ECG and EEG, but instrumentation amplifiers provide more accurate and stable output in noisy environments.

Noise Rejection and Common-Mode Performance

Instrumentation amplifiers offer superior noise rejection and common-mode performance compared to differential amplifiers due to their high input impedance and precise gain adjustment. Differential amplifiers typically have lower common-mode rejection ratio (CMRR), making them less effective at eliminating noise from common-mode signals. Your choice should favor instrumentation amplifiers when high accuracy and minimal interference in noisy environments are critical.

Accuracy and Precision Comparison

Instrumentation amplifiers deliver superior accuracy and precision compared to differential amplifiers due to their higher common-mode rejection ratio (CMRR) and low input offset voltage. The three-op-amp architecture of instrumentation amplifiers minimizes noise and drift, ensuring consistent gain and precise signal amplification. Differential amplifiers, while simpler, typically exhibit greater susceptibility to input offset errors and lower CMRR, which can degrade measurement accuracy in low-level or high-noise environments.

Input Impedance Differences

Differential amplifiers typically have moderate input impedance, which can affect signal integrity when measuring weak signals from high-impedance sources. Instrumentation amplifiers are designed with very high input impedance, often in the megaohm range, minimizing loading effects and preserving signal accuracy. Choosing the right amplifier for Your application depends largely on the input impedance requirements to ensure optimal performance and signal fidelity.

Gain Control and Flexibility

A differential amplifier offers basic gain control through a single gain-setting resistor, providing limited flexibility in adjusting the amplification factor, which makes it suitable for simple signal processing tasks. In contrast, an instrumentation amplifier features multiple gain resistors and internal stages, allowing precise and easily adjustable gain settings with high input impedance, enabling superior flexibility for accurate low-level signal amplification in noisy environments. This enhanced gain control and adaptability make instrumentation amplifiers preferred in medical devices, sensor interfaces, and precision measurement systems.

Power Supply and Design Considerations

Differential amplifiers typically require a dual power supply (positive and negative voltages) to handle input signals that swing around zero volts, impacting the complexity and cost of the design. Instrumentation amplifiers are often designed to operate on a single power supply, making them suitable for battery-powered and portable applications while incorporating input buffer stages to maintain high input impedance and precise gain. Careful consideration of power supply requirements influences the choice between these amplifiers, with instrumentation amplifiers providing better stability and noise rejection in low-voltage and low-power environments.

Choosing the Right Amplifier for Your Application

Selecting between a differential amplifier and an instrumentation amplifier depends on the need for precision and noise rejection in your application. Instrumentation amplifiers offer high input impedance, superior common-mode rejection ratio (CMRR), and ease of gain adjustment, making them ideal for accurate sensor signal conditioning. Differential amplifiers provide simpler design with lower cost but are better suited for applications where noise immunity and precise gain control are less critical.

differential amplifier vs instrumentation amplifier Infographic

electrown.com

electrown.com