CAN FD offers increased data payload size and faster data rates compared to traditional CAN, enhancing communication efficiency in automotive and industrial networks. Discover how these advancements can improve Your system's performance by reading the rest of the article.

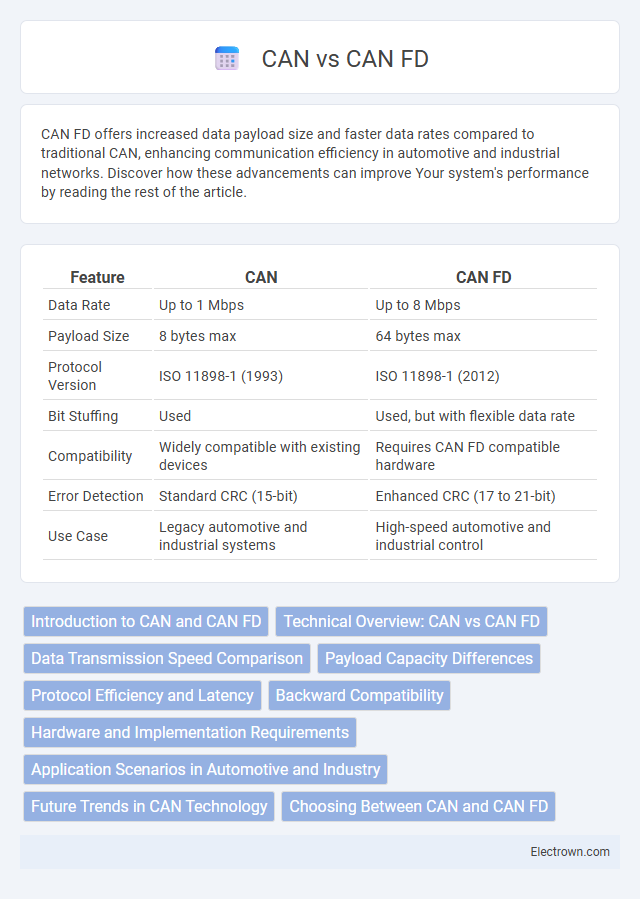

Table of Comparison

| Feature | CAN | CAN FD |

|---|---|---|

| Data Rate | Up to 1 Mbps | Up to 8 Mbps |

| Payload Size | 8 bytes max | 64 bytes max |

| Protocol Version | ISO 11898-1 (1993) | ISO 11898-1 (2012) |

| Bit Stuffing | Used | Used, but with flexible data rate |

| Compatibility | Widely compatible with existing devices | Requires CAN FD compatible hardware |

| Error Detection | Standard CRC (15-bit) | Enhanced CRC (17 to 21-bit) |

| Use Case | Legacy automotive and industrial systems | High-speed automotive and industrial control |

Introduction to CAN and CAN FD

Controller Area Network (CAN) is a robust vehicle bus standard designed for microcontroller communication in automotive and industrial applications, supporting data rates up to 1 Mbps. CAN FD (Flexible Data-rate) extends the original CAN protocol by increasing data payload from 8 to 64 bytes and boosting bit rates beyond 1 Mbps during the data phase. These enhancements enable faster transmission and improved efficiency for complex, data-intensive control systems.

Technical Overview: CAN vs CAN FD

CAN FD (Controller Area Network Flexible Data-rate) enhances the traditional CAN protocol by allowing faster data transmission rates up to 8 Mbps compared to CAN's 1 Mbps limit. CAN FD increases payload size from 8 bytes to 64 bytes per frame, improving efficiency and reducing overhead for high-data applications. Your systems will benefit from CAN FD's ability to handle larger data loads with quicker communication while maintaining backward compatibility with classical CAN networks.

Data Transmission Speed Comparison

CAN FD significantly improves data transmission speed compared to traditional CAN by allowing data rates up to 8 Mbps, whereas classic CAN maxes out at 1 Mbps. This increased speed is achieved through flexible data-rate technology, enabling faster communication and larger payload sizes up to 64 bytes per frame. Your systems will benefit from reduced latency and enhanced real-time performance in high-demand automotive and industrial applications.

Payload Capacity Differences

CAN FD significantly increases payload capacity compared to classic CAN by supporting data frames up to 64 bytes, whereas classic CAN is limited to 8 bytes per frame. This expansion allows CAN FD to handle larger volumes of data per message, improving network efficiency and reducing communication overhead in automotive and industrial applications. Increased payload capacity directly enhances real-time data transfer and system performance, crucial for complex electronic control units (ECUs).

Protocol Efficiency and Latency

CAN FD (Flexible Data-rate) enhances protocol efficiency by allowing larger data payloads up to 64 bytes compared to the standard CAN's 8 bytes, reducing the overhead per transmitted byte. This increase in payload size, coupled with faster bit rates during the data phase, significantly lowers latency and improves real-time communication performance in complex automotive or industrial networks. Your systems benefit from CAN FD's optimized bandwidth utilization and reduced transmission time, making it ideal for applications demanding high-speed, low-latency messaging.

Backward Compatibility

CAN FD maintains full backward compatibility with classical CAN by supporting standard CAN frame formats and bit timings, allowing existing CAN devices to communicate seamlessly on a CAN FD network. While CAN FD introduces faster data rates up to 8 Mbps and larger payloads up to 64 bytes, it reverts to classical CAN specifications during communication with legacy nodes. This compatibility ensures gradual network upgrades without requiring complete hardware replacements in automotive and industrial applications.

Hardware and Implementation Requirements

CAN FD requires more advanced hardware components such as CAN FD-compatible transceivers and controllers to handle larger data frames and faster bit rates compared to traditional CAN systems. Implementing CAN FD necessitates updated firmware and software protocols capable of managing variable data lengths and improved error detection mechanisms. Integration of CAN FD in existing systems often involves hardware upgrades and revalidation to ensure compatibility with extended data payloads and increased communication speed.

Application Scenarios in Automotive and Industry

CAN FD (Flexible Data-Rate) enables higher data throughput and larger payloads compared to classic CAN, making it ideal for advanced automotive applications such as autonomous driving systems and over-the-air updates. In industrial settings, CAN FD supports faster communication and enhanced diagnostic capabilities crucial for complex machinery and real-time control systems. Your choice between CAN FD and classic CAN depends on the required bandwidth and data reliability for specific applications within automotive or industrial environments.

Future Trends in CAN Technology

CAN FD (Controller Area Network with Flexible Data-Rate) enhances traditional CAN by supporting larger data payloads up to 64 bytes and faster bit rates reaching 8 Mbps, addressing the growing demand for high-speed communication in automotive and industrial applications. Future trends in CAN technology emphasize increased integration of CAN FD with emerging automotive Ethernet networks, enabling seamless data exchange in advanced driver-assistance systems (ADAS) and autonomous vehicles. Innovations in CAN transceivers, such as improved error detection and low-power operation, aim to boost reliability and energy efficiency while supporting complex in-vehicle network architectures.

Choosing Between CAN and CAN FD

Choosing between CAN and CAN FD depends on data rate requirements and message payload size; CAN offers speeds up to 1 Mbps with 8-byte frames, while CAN FD extends speed to 8 Mbps and payloads up to 64 bytes. CAN FD is suitable for applications demanding higher bandwidth and faster communication, such as advanced automotive systems and industrial automation. Legacy systems or networks prioritizing compatibility and simplicity may still prefer classic CAN for its widespread adoption and proven reliability.

CAN FD vs CAN Infographic

electrown.com

electrown.com