VR sensors and Hall effect sensors both detect rotational speed but operate on different principles; VR sensors generate AC voltage through magnetic induction while Hall effect sensors use a semiconductor to produce a voltage signal proportional to magnetic field strength. Understanding these differences can help you choose the right sensor for your application, so continue reading to explore their advantages and best use cases.

Table of Comparison

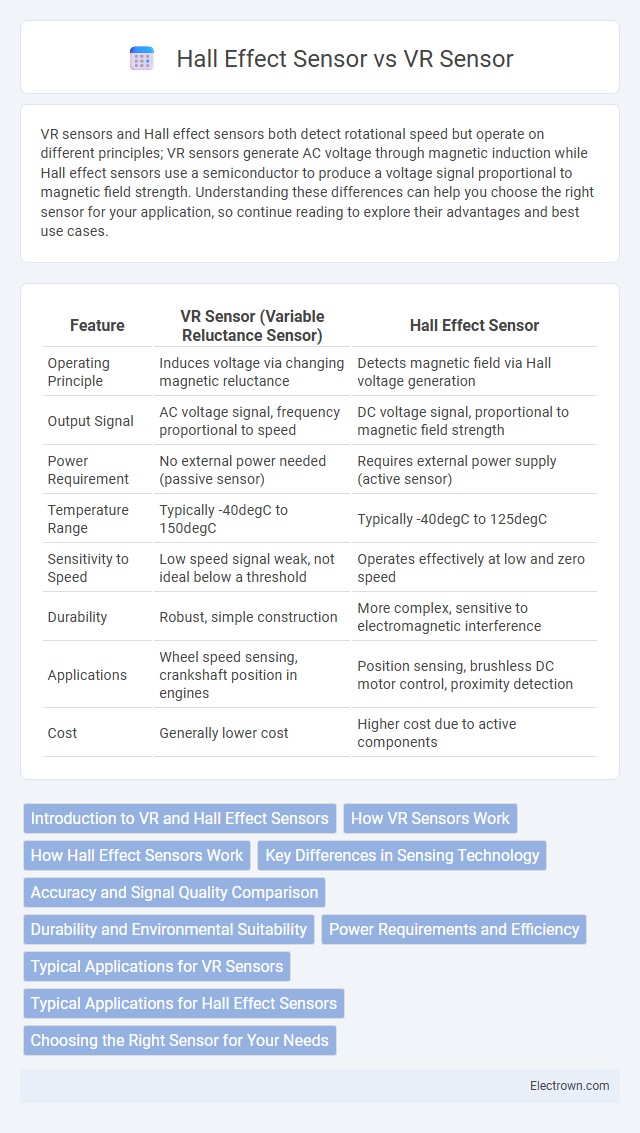

| Feature | VR Sensor (Variable Reluctance Sensor) | Hall Effect Sensor |

|---|---|---|

| Operating Principle | Induces voltage via changing magnetic reluctance | Detects magnetic field via Hall voltage generation |

| Output Signal | AC voltage signal, frequency proportional to speed | DC voltage signal, proportional to magnetic field strength |

| Power Requirement | No external power needed (passive sensor) | Requires external power supply (active sensor) |

| Temperature Range | Typically -40degC to 150degC | Typically -40degC to 125degC |

| Sensitivity to Speed | Low speed signal weak, not ideal below a threshold | Operates effectively at low and zero speed |

| Durability | Robust, simple construction | More complex, sensitive to electromagnetic interference |

| Applications | Wheel speed sensing, crankshaft position in engines | Position sensing, brushless DC motor control, proximity detection |

| Cost | Generally lower cost | Higher cost due to active components |

Introduction to VR and Hall Effect Sensors

VR (Variable Reluctance) sensors detect changes in magnetic field by measuring variations in magnetic reluctance, making them ideal for rotational speed and position sensing. Hall Effect sensors rely on the Hall voltage generated when a magnetic field passes perpendicular to a current-carrying conductor, enabling precise detection of magnetic field strength and polarity. Your choice between VR and Hall Effect sensors depends on factors such as signal output type, environmental conditions, and required sensitivity.

How VR Sensors Work

VR sensors operate by detecting changes in magnetic reluctance as a rotating toothed wheel passes by, generating an AC voltage signal proportional to the speed and position of the target. These sensors are passive devices that do not require an external power source, relying solely on the magnetic field changes to produce their output. Your application can benefit from VR sensors' simplicity and durability when precise speed or position sensing is needed without continuous power consumption.

How Hall Effect Sensors Work

Hall Effect sensors operate by detecting changes in magnetic fields through the Hall voltage generated across a conductive material when exposed to a perpendicular magnetic field. These sensors convert magnetic flux variations into electrical signals, enabling precise measurement of position, speed, or current. Their contactless operation and high sensitivity make them ideal for diverse applications such as automotive ignition systems, brushless DC motors, and proximity sensing.

Key Differences in Sensing Technology

VR (Variable Reluctance) sensors detect changes in magnetic reluctance caused by a ferromagnetic target, generating an AC voltage signal proportional to speed or position without requiring power. Hall effect sensors operate based on the Hall effect principle, producing a DC voltage output in response to a magnetic field, enabling precise measurement of magnetic flux density. VR sensors excel in high-speed applications with robust durability, while Hall effect sensors provide greater sensitivity, linear output, and functionality in low-speed or static conditions.

Accuracy and Signal Quality Comparison

VR sensors offer high accuracy and consistent signal quality in low-speed and high-frequency applications due to their magnetic reluctance principle, generating clean sine wave outputs with minimal noise. Hall effect sensors provide excellent accuracy across a broader speed range, especially at low speeds, by producing digital signals with high signal-to-noise ratios and immunity to external magnetic interference. While VR sensors may suffer from weaker signals at very low speeds, Hall effect sensors maintain stable, precise output, making them preferable for advanced automotive and industrial applications requiring reliable position feedback.

Durability and Environmental Suitability

VR sensors boast high durability due to their simple construction without magnets, making them ideal for harsh environments with elevated temperatures, vibrations, and contaminants. Hall effect sensors, while sensitive to magnetic fields, typically require protective encapsulation to maintain performance in extreme conditions and can be prone to magnetic interference. In industrial applications involving exposure to dirt, moisture, or strong electromagnetic fields, VR sensors often provide superior environmental suitability and longer operational life.

Power Requirements and Efficiency

VR sensors operate without external power due to their passive electromagnetic induction design, resulting in minimal energy consumption and high efficiency in automotive applications. Hall effect sensors require a continuous external power supply, typically drawing low current, but their active nature leads to slightly higher power usage. In efficiency terms, VR sensors excel in conditions where energy conservation is crucial, while Hall effect sensors offer consistent output at the cost of increased power demand.

Typical Applications for VR Sensors

VR sensors are widely used in automotive applications for accurately detecting crankshaft and camshaft positions, crucial for engine timing and fuel injection systems. Their high precision makes them ideal for industrial machinery where rotational speed and position monitoring are essential for operational efficiency. You will find VR sensors commonly integrated into aerospace systems for reliable feedback in aircraft control mechanisms.

Typical Applications for Hall Effect Sensors

Hall effect sensors are widely used in automotive applications for detecting the position of crankshafts and camshafts, ensuring precise engine timing. These sensors also find applications in brushless DC motors for speed and rotation direction detection, enhancing motor control efficiency. In consumer electronics, Hall effect sensors enable contactless switch operations and provide accurate magnetic field measurements for proximity sensing.

Choosing the Right Sensor for Your Needs

When choosing the right sensor for your needs, consider that VR (Variable Reluctance) sensors excel in high-speed applications with robust durability and are ideal for detecting changes in magnetic fields without requiring external power. Hall effect sensors provide precise, low-speed sensing with the added benefit of digital output and lower noise, making them suitable for automotive position and speed detection. Your decision should weigh factors like signal type, operating environment, and power availability to ensure optimal performance and reliability.

VR sensor vs Hall effect sensor Infographic

electrown.com

electrown.com