Power MOSFETs offer higher switching speeds and better efficiency with lower gate drive power compared to Power BJTs, which have slower switching times but can handle higher current densities. Explore the article to understand how Your choice between Power MOSFET and Power BJT impacts performance in various applications.

Table of Comparison

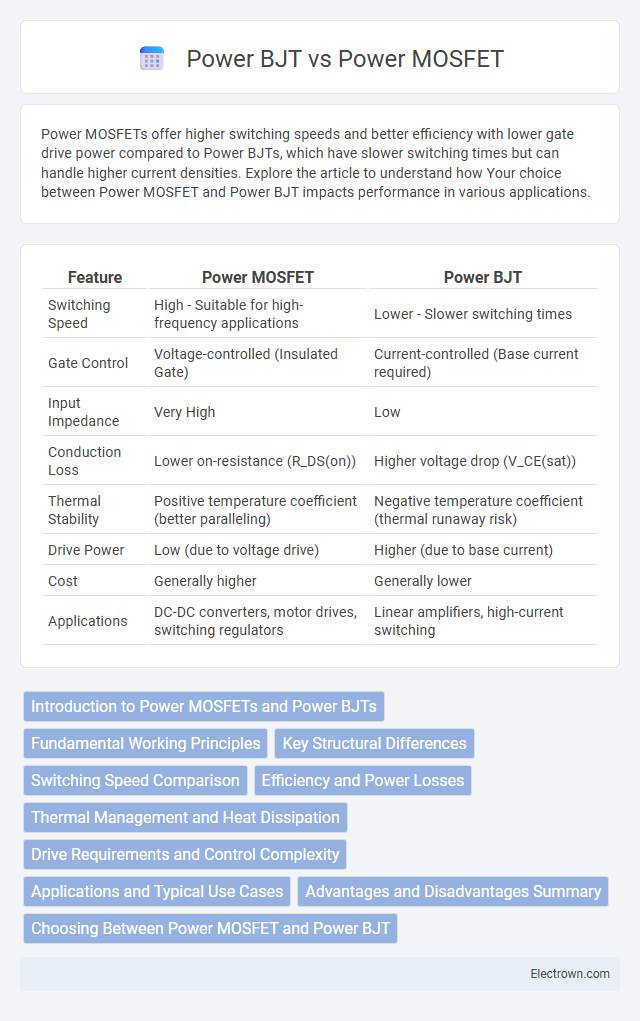

| Feature | Power MOSFET | Power BJT |

|---|---|---|

| Switching Speed | High - Suitable for high-frequency applications | Lower - Slower switching times |

| Gate Control | Voltage-controlled (Insulated Gate) | Current-controlled (Base current required) |

| Input Impedance | Very High | Low |

| Conduction Loss | Lower on-resistance (R_DS(on)) | Higher voltage drop (V_CE(sat)) |

| Thermal Stability | Positive temperature coefficient (better paralleling) | Negative temperature coefficient (thermal runaway risk) |

| Drive Power | Low (due to voltage drive) | Higher (due to base current) |

| Cost | Generally higher | Generally lower |

| Applications | DC-DC converters, motor drives, switching regulators | Linear amplifiers, high-current switching |

Introduction to Power MOSFETs and Power BJTs

Power MOSFETs feature high input impedance and fast switching speeds, making them ideal for low-voltage, high-frequency applications. Power BJTs offer robust current handling and better performance in linear amplification due to their bipolar conduction mechanism. Your choice between these devices depends on factors like efficiency, switching speed, and thermal management requirements.

Fundamental Working Principles

Power MOSFETs operate by controlling voltage at the gate terminal to create an electric field that modulates the conductivity of a semiconductor channel, enabling rapid switching with low gate current. Power BJTs function through current-driven injection of minority carriers from the base to the collector, resulting in higher gain but slower switching speeds. The voltage-controlled operation of MOSFETs leads to lower gate power consumption and faster switching compared to the current-controlled mechanism of BJTs.

Key Structural Differences

Power MOSFETs feature a metal-oxide-semiconductor gate structure that controls current flow through an insulated channel, enabling high-speed switching and low gate drive power. Power BJTs operate through bipolar conduction, where current flows via both electrons and holes in a junction transistor structure, resulting in higher gain but slower switching speeds. Understanding these key structural differences helps optimize Your choice for applications requiring efficiency, switching frequency, and thermal performance.

Switching Speed Comparison

Power MOSFETs exhibit significantly faster switching speeds compared to Power BJTs due to their voltage-driven gate that requires minimal input current, reducing turn-on and turn-off delays. This characteristic makes MOSFETs ideal for high-frequency applications such as DC-DC converters and motor drives, where rapid switching enhances efficiency and performance. Your choice of a Power MOSFET can optimize switching speed, minimizing power losses and improving overall circuit responsiveness.

Efficiency and Power Losses

Power MOSFETs demonstrate higher efficiency and lower power losses compared to Power BJTs due to their majority carrier conduction, which reduces switching losses significantly. The R_DS(on) resistance in MOSFETs enables faster switching speeds and minimal conduction losses, making them ideal for high-frequency applications. Power BJTs suffer from higher saturation voltage and slower switching, leading to greater power dissipation and decreased overall efficiency in power conversion systems.

Thermal Management and Heat Dissipation

Power MOSFETs exhibit lower on-resistance (R_DS(on)) compared to power BJTs, resulting in reduced conduction losses and improved thermal efficiency during high-frequency switching applications. The unipolar conduction mechanism of MOSFETs generates less heat, allowing for more compact heat sinks and simplified thermal management designs. In contrast, power BJTs require more robust cooling solutions due to higher saturation voltage and significant base current losses that produce greater heat dissipation under heavy load conditions.

Drive Requirements and Control Complexity

Power MOSFETs require low gate drive voltage and negligible continuous gate current, enabling simpler and more efficient drive circuitry compared to Power BJTs, which need significant base current and more complex drive circuits to maintain proper operation. The voltage-driven nature of MOSFETs allows for faster switching speeds and easier integration with digital control signals, while BJTs require careful base current control to avoid saturation and reduce switching losses. Overall, Power MOSFETs offer lower control complexity and better performance in high-frequency switching applications than Power BJTs.

Applications and Typical Use Cases

Power MOSFETs excel in high-frequency switching applications such as DC-DC converters, motor drives, and power supplies due to their fast switching speed and high efficiency. Power BJTs are preferred in high-current, low-frequency applications like audio amplifiers and linear regulators because of their superior current handling and linearity. Both devices serve critical roles in power electronics, with MOSFETs dominating switching tasks and BJTs favored for their robustness in analog circuits.

Advantages and Disadvantages Summary

Power MOSFETs offer faster switching speeds, higher efficiency, and simpler drive requirements compared to Power BJTs, making them ideal for high-frequency applications. Power BJTs provide better conductivity and higher current capacity at lower costs but suffer from slower switching speeds and more complex drive circuitry. The choice depends on application needs, with MOSFETs favored in low-voltage, high-speed circuits, while BJTs remain suitable for high-current, lower-frequency environments.

Choosing Between Power MOSFET and Power BJT

Choosing between Power MOSFET and Power BJT depends on switching speed, efficiency, and application voltage. Power MOSFETs offer faster switching, lower gate drive power, and better efficiency in low-voltage applications under 200V, making them ideal for high-frequency circuits. Power BJTs handle higher voltages and have higher current gain but generate more heat and have slower switching, so your choice should align with the specific requirements of power dissipation and switching frequency in your design.

Power MOSFET vs Power BJT Infographic

electrown.com

electrown.com