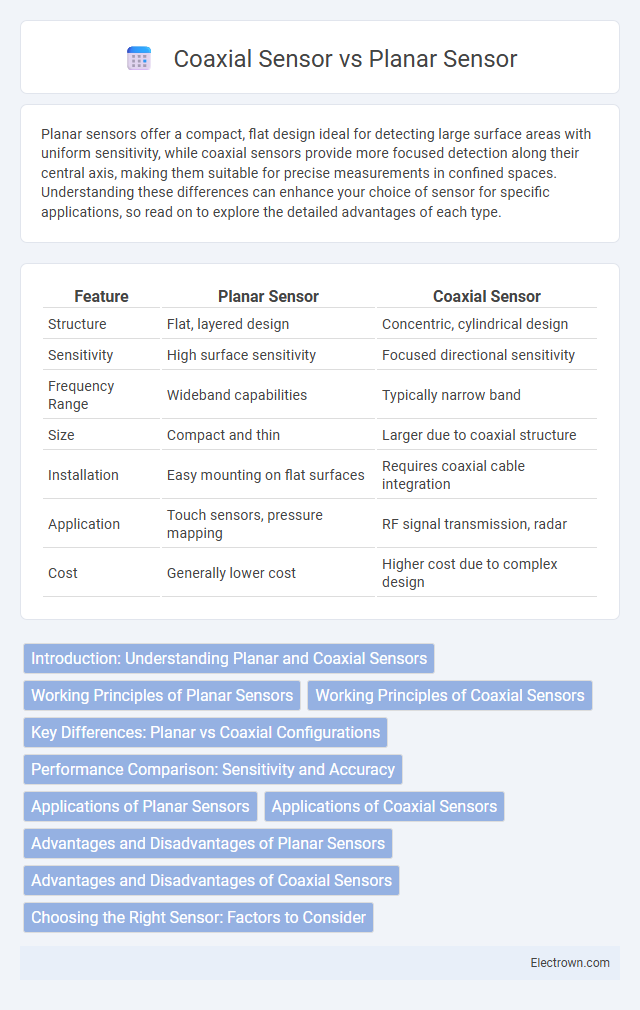

Planar sensors offer a compact, flat design ideal for detecting large surface areas with uniform sensitivity, while coaxial sensors provide more focused detection along their central axis, making them suitable for precise measurements in confined spaces. Understanding these differences can enhance your choice of sensor for specific applications, so read on to explore the detailed advantages of each type.

Table of Comparison

| Feature | Planar Sensor | Coaxial Sensor |

|---|---|---|

| Structure | Flat, layered design | Concentric, cylindrical design |

| Sensitivity | High surface sensitivity | Focused directional sensitivity |

| Frequency Range | Wideband capabilities | Typically narrow band |

| Size | Compact and thin | Larger due to coaxial structure |

| Installation | Easy mounting on flat surfaces | Requires coaxial cable integration |

| Application | Touch sensors, pressure mapping | RF signal transmission, radar |

| Cost | Generally lower cost | Higher cost due to complex design |

Introduction: Understanding Planar and Coaxial Sensors

Planar sensors feature flat, two-dimensional designs that enable high-resolution detection across broad surfaces, making them ideal for applications requiring precise spatial mapping. Coaxial sensors utilize concentric cylindrical conductors to transmit and receive signals with enhanced electromagnetic shielding, providing superior signal integrity in harsh environments. Your choice between planar and coaxial sensors depends on specific measurement needs, including spatial resolution, environmental conditions, and installation constraints.

Working Principles of Planar Sensors

Planar sensors operate by utilizing a flat, two-dimensional configuration where electrodes are arranged on a single plane to detect changes in physical parameters such as pressure, temperature, or chemical composition. The working principle involves the interaction between the analyte and the sensor's surface, which alters electrical properties like capacitance, resistance, or impedance, enabling precise measurements. This planar architecture allows for compact design, ease of integration with electronic circuits, and enhanced sensitivity in monitoring various environmental or biological signals.

Working Principles of Coaxial Sensors

Coaxial sensors operate based on the transmission and reception of electromagnetic waves along a central conductor surrounded by a cylindrical shield, enabling precise measurement of material properties such as permittivity and conductivity. The sensor's dielectric medium influences the velocity and attenuation of the signals, allowing accurate detection of changes in the measured substance. This principle makes coaxial sensors ideal for applications in fluid level measurement, material characterization, and industrial process monitoring.

Key Differences: Planar vs Coaxial Configurations

Planar sensors feature electrodes arranged on a flat substrate surface, resulting in a compact design with high sensitivity for surface-level measurements. Coaxial sensors use a concentric electrode configuration, allowing for deeper penetration and more uniform field distribution in subsurface sensing applications. The key difference lies in their geometry and field orientation, where planar excels in surface analysis while coaxial is preferred for volumetric and depth profiling.

Performance Comparison: Sensitivity and Accuracy

Planar sensors generally offer higher sensitivity due to their larger surface area, enabling more precise detection of minute changes in the measured parameter. Coaxial sensors provide improved accuracy by minimizing signal loss and interference through their concentric design, resulting in more reliable data acquisition. Your choice between planar and coaxial sensors should consider the specific sensitivity and accuracy requirements of your application to optimize performance.

Applications of Planar Sensors

Planar sensors are extensively used in applications requiring compact and low-profile solutions, such as touchscreens, fingerprint recognition, and proximity detection in smartphones and wearables. Their flat and thin design enables integration into flexible electronics, medical devices, and automotive sensing systems where space constraints are critical. Planar sensors also excel in environmental monitoring and industrial automation due to their high sensitivity and ease of fabrication on various substrates.

Applications of Coaxial Sensors

Coaxial sensors excel in applications requiring high-frequency signal transmission and precise impedance control, making them ideal for radar systems, telecommunications, and medical imaging equipment. Their robust design supports reliable data transfer in harsh environments such as aerospace and industrial automation. The sensors' ability to minimize signal loss and interference enhances performance in wireless communication and antenna measurements.

Advantages and Disadvantages of Planar Sensors

Planar sensors offer advantages such as compact design, ease of integration, and lower manufacturing costs, making them suitable for applications with space constraints. Their flat surface allows for uniform sensing and better sensitivity in certain environments but may suffer from limited range and susceptibility to electromagnetic interference compared to coaxial sensors. The disadvantages include reduced signal penetration depth and potential accuracy issues in complex or layered materials, which can limit their effectiveness in some industrial or medical imaging scenarios.

Advantages and Disadvantages of Coaxial Sensors

Coaxial sensors offer high sensitivity and excellent signal-to-noise ratio, making them ideal for precise measurements in challenging environments. Their compact design supports easy integration into tight spaces, but they can be more expensive and complex to manufacture compared to planar sensors. Your choice depends on the application requirements, balancing performance needs with cost considerations.

Choosing the Right Sensor: Factors to Consider

When choosing the right sensor between planar and coaxial types, consider factors such as signal depth, resolution, and environmental conditions. Planar sensors typically offer higher spatial resolution and are better suited for surface or near-surface measurements, while coaxial sensors provide greater penetration depth for subsurface analysis. Your application's specific requirements for accuracy, measurement depth, and interference resistance will determine the optimal sensor choice.

Planar vs Coaxial Sensor Infographic

electrown.com

electrown.com