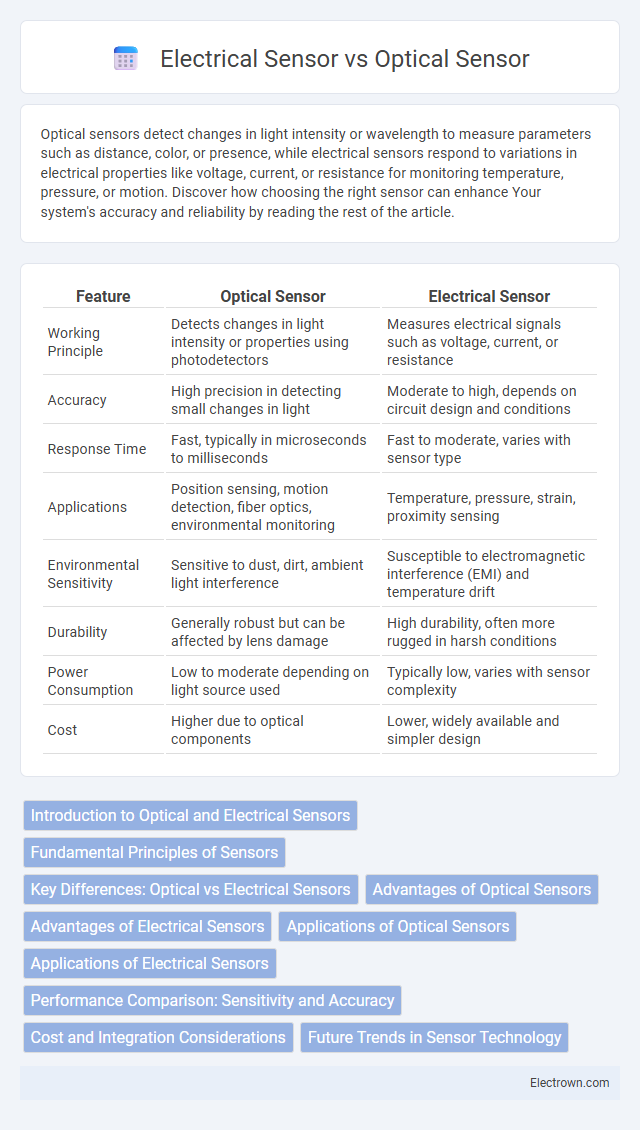

Optical sensors detect changes in light intensity or wavelength to measure parameters such as distance, color, or presence, while electrical sensors respond to variations in electrical properties like voltage, current, or resistance for monitoring temperature, pressure, or motion. Discover how choosing the right sensor can enhance Your system's accuracy and reliability by reading the rest of the article.

Table of Comparison

| Feature | Optical Sensor | Electrical Sensor |

|---|---|---|

| Working Principle | Detects changes in light intensity or properties using photodetectors | Measures electrical signals such as voltage, current, or resistance |

| Accuracy | High precision in detecting small changes in light | Moderate to high, depends on circuit design and conditions |

| Response Time | Fast, typically in microseconds to milliseconds | Fast to moderate, varies with sensor type |

| Applications | Position sensing, motion detection, fiber optics, environmental monitoring | Temperature, pressure, strain, proximity sensing |

| Environmental Sensitivity | Sensitive to dust, dirt, ambient light interference | Susceptible to electromagnetic interference (EMI) and temperature drift |

| Durability | Generally robust but can be affected by lens damage | High durability, often more rugged in harsh conditions |

| Power Consumption | Low to moderate depending on light source used | Typically low, varies with sensor complexity |

| Cost | Higher due to optical components | Lower, widely available and simpler design |

Introduction to Optical and Electrical Sensors

Optical sensors detect changes in light properties such as intensity, wavelength, or phase to measure physical quantities, relying on components like photodiodes, LEDs, and fiber optics for high precision in applications including imaging and environmental monitoring. Electrical sensors measure variations in electrical parameters such as voltage, current, or resistance to sense phenomena like temperature, pressure, or motion, often utilizing components like thermistors, piezoelectric elements, and Hall effect devices. Both sensor types play critical roles in automation, robotics, and IoT systems, with optical sensors offering advantages in non-contact detection and electrical sensors excelling in direct measurement scenarios.

Fundamental Principles of Sensors

Optical sensors detect changes in light intensity, wavelength, or phase to sense physical properties, utilizing components such as photodiodes and LEDs for precise measurement. Electrical sensors operate by converting physical stimuli into electrical signals, often relying on changes in resistance, capacitance, or voltage for accurate detection. Understanding these fundamental principles enables you to select the most suitable sensor technology for applications requiring high sensitivity and reliability.

Key Differences: Optical vs Electrical Sensors

Optical sensors detect changes in light, using technologies like photodiodes, whereas electrical sensors rely on variations in electrical properties such as voltage, current, or resistance. Optical sensors offer high precision and non-contact measurement, ideal for applications requiring accurate detection of light intensity or presence. Electrical sensors provide robust, cost-effective solutions for sensing parameters like temperature, pressure, or position, making them suitable for diverse industrial and consumer uses.

Advantages of Optical Sensors

Optical sensors offer high sensitivity and precision in detecting changes in light intensity, making them ideal for applications requiring accurate measurements. They provide non-contact sensing, reducing wear and tear, and are immune to electromagnetic interference, ensuring reliable performance in harsh environments. Your systems benefit from faster response times and the ability to detect a wide range of physical parameters such as distance, color, and presence with minimal maintenance.

Advantages of Electrical Sensors

Electrical sensors offer high durability and reliability in harsh environments due to their resistance to dust, moisture, and vibrations. They provide fast response times and precise measurements, making them ideal for industrial automation and real-time monitoring applications. These sensors generally have lower production costs and simpler integration with electronic systems compared to optical sensors.

Applications of Optical Sensors

Optical sensors are extensively used in applications such as industrial automation for precise object detection, medical devices for non-invasive monitoring, and environmental monitoring systems to measure light intensity or detect pollutants. Their ability to provide high sensitivity and fast response times makes them ideal for barcode scanners, fiber optic communication, and proximity sensing in robotics. Compared to electrical sensors, optical sensors excel in environments requiring immunity to electromagnetic interference and where non-contact measurement is critical.

Applications of Electrical Sensors

Electrical sensors are widely applied in industrial automation for monitoring voltage, current, and resistance to ensure equipment performance and safety. They are essential in automotive systems for detecting position, speed, and temperature, enhancing vehicle reliability and efficiency. Electrical sensors also play a critical role in consumer electronics to measure touch, proximity, and environmental conditions, enabling advanced device functionality.

Performance Comparison: Sensitivity and Accuracy

Optical sensors generally offer higher sensitivity and greater accuracy compared to electrical sensors due to their ability to detect minute changes in light intensity and wavelength. Electrical sensors may experience more signal noise and interference, which can reduce precision and limit sensitivity, especially in low-signal environments. Your choice between optical and electrical sensors should consider the specific application requirements for detection range and measurement accuracy.

Cost and Integration Considerations

Optical sensors typically incur higher initial costs due to advanced components and precise calibration requirements, while electrical sensors often offer more budget-friendly options for basic applications. Integration of optical sensors demands careful alignment and clean environments, increasing complexity and installation time, whereas electrical sensors are generally easier to embed in existing systems with minimal modifications. Your choice should balance the higher precision and reliability of optical sensors against the cost-effectiveness and simpler integration of electrical alternatives.

Future Trends in Sensor Technology

Optical sensors are rapidly advancing with innovations like integrated photonics and AI-enhanced signal processing, enabling higher precision and faster response times compared to traditional electrical sensors. Electrical sensors continue to evolve with improvements in nanomaterials and energy efficiency, making them highly adaptable for IoT and wearable applications. Your choice between optical and electrical sensors should consider these emerging trends, as optical technologies are poised for breakthroughs in sensing accuracy, while electrical sensors excel in miniaturization and connectivity.

Optical vs Electrical Sensor Infographic

electrown.com

electrown.com