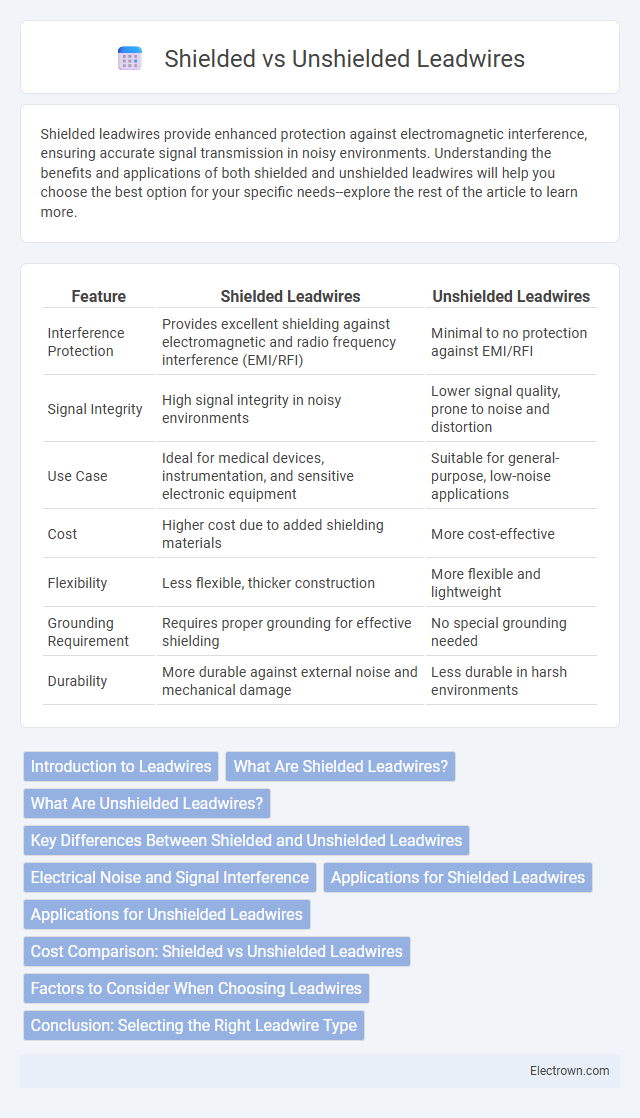

Shielded leadwires provide enhanced protection against electromagnetic interference, ensuring accurate signal transmission in noisy environments. Understanding the benefits and applications of both shielded and unshielded leadwires will help you choose the best option for your specific needs--explore the rest of the article to learn more.

Table of Comparison

| Feature | Shielded Leadwires | Unshielded Leadwires |

|---|---|---|

| Interference Protection | Provides excellent shielding against electromagnetic and radio frequency interference (EMI/RFI) | Minimal to no protection against EMI/RFI |

| Signal Integrity | High signal integrity in noisy environments | Lower signal quality, prone to noise and distortion |

| Use Case | Ideal for medical devices, instrumentation, and sensitive electronic equipment | Suitable for general-purpose, low-noise applications |

| Cost | Higher cost due to added shielding materials | More cost-effective |

| Flexibility | Less flexible, thicker construction | More flexible and lightweight |

| Grounding Requirement | Requires proper grounding for effective shielding | No special grounding needed |

| Durability | More durable against external noise and mechanical damage | Less durable in harsh environments |

Introduction to Leadwires

Leadwires are essential components in electrical and medical devices, designed to transmit signals or power efficiently. Shielded leadwires feature an additional conductive layer that protects against electromagnetic interference (EMI), ensuring signal integrity in environments with high electrical noise. Your choice between shielded and unshielded leadwires should consider the application's susceptibility to interference, with shielded leadwires offering enhanced performance in sensitive or noise-prone settings.

What Are Shielded Leadwires?

Shielded leadwires feature a protective layer, typically made of metal, that surrounds the internal conductors to block electromagnetic interference (EMI) and reduce signal noise for precise data transmission. These leadwires are essential in environments with high electrical noise, ensuring signal integrity and preventing data corruption. Your choice of shielded leadwires can significantly improve performance in sensitive electronic applications where signal clarity is critical.

What Are Unshielded Leadwires?

Unshielded leadwires are electrical cables without an insulating shield layer, commonly used in low-interference environments where electromagnetic interference (EMI) is minimal. These leadwires offer cost-effective flexibility and ease of installation but may be more susceptible to noise and signal degradation compared to shielded alternatives. Your choice of unshielded leadwires should consider the surrounding environment and specific application requirements to ensure optimal performance.

Key Differences Between Shielded and Unshielded Leadwires

Shielded leadwires feature a conductive layer that protects against electromagnetic interference (EMI), ensuring signal integrity in noisy environments, while unshielded leadwires lack this protective layer, making them more vulnerable to interference. Shielded cables are typically thicker, costlier, and better suited for applications requiring high signal fidelity, such as medical devices or industrial machinery. You should choose shielded leadwires when minimizing noise is critical, whereas unshielded leadwires work well in low-interference settings or where cost and flexibility are priorities.

Electrical Noise and Signal Interference

Shielded leadwires provide a conductive barrier that minimizes electrical noise and reduces signal interference, ensuring cleaner and more reliable data transmission in environments with strong electromagnetic fields. Unshielded leadwires lack this protective layer, making them more susceptible to signal degradation caused by external electromagnetic interference (EMI). Selecting shielded leadwires is crucial for applications requiring high signal integrity and accurate measurements in electrically noisy environments.

Applications for Shielded Leadwires

Shielded leadwires are essential in environments with high electromagnetic interference (EMI), such as industrial machinery, medical devices, and aerospace applications, where signal integrity and noise reduction are critical. These leadwires protect delicate sensor signals by minimizing electromagnetic noise and preventing data corruption, ensuring accurate and reliable performance. When your application involves precise measurements or operates near heavy electrical equipment, choosing shielded leadwires significantly enhances system stability and safety.

Applications for Unshielded Leadwires

Unshielded leadwires are commonly used in applications where electromagnetic interference (EMI) is minimal or non-critical, such as residential wiring, simple sensor connections, and basic electrical devices. Their flexibility and cost-effectiveness make them ideal for internal connections within electronic equipment and appliances that operate in low-noise environments. These leadwires are preferred for short-distance circuits and general-purpose wiring where shielding is unnecessary.

Cost Comparison: Shielded vs Unshielded Leadwires

Shielded leadwires generally incur higher costs due to the additional materials and manufacturing processes needed to integrate protective shielding that reduces electromagnetic interference. Unshielded leadwires are more cost-effective and suitable for less noise-sensitive applications where budget constraints are a priority. Your choice should balance cost considerations with the performance requirements of your specific electrical environment.

Factors to Consider When Choosing Leadwires

Choosing between shielded and unshielded leadwires depends on factors such as electromagnetic interference (EMI) levels, signal integrity requirements, and environmental conditions. Shielded leadwires are essential in high-EMI environments to prevent noise and signal degradation, while unshielded wires are suitable for low-interference applications with less stringent noise control. Consider cable flexibility, cost, and installation complexity alongside the electrical and mechanical demands of the specific application.

Conclusion: Selecting the Right Leadwire Type

Choosing between shielded and unshielded leadwires depends on your specific application and environmental conditions. Shielded leadwires offer superior protection against electromagnetic interference, making them ideal for sensitive electronic devices or noisy industrial settings. Unshielded leadwires provide a cost-effective solution for low-interference environments where minimal signal disruption occurs.

Shielded vs Unshielded Leadwires Infographic

electrown.com

electrown.com