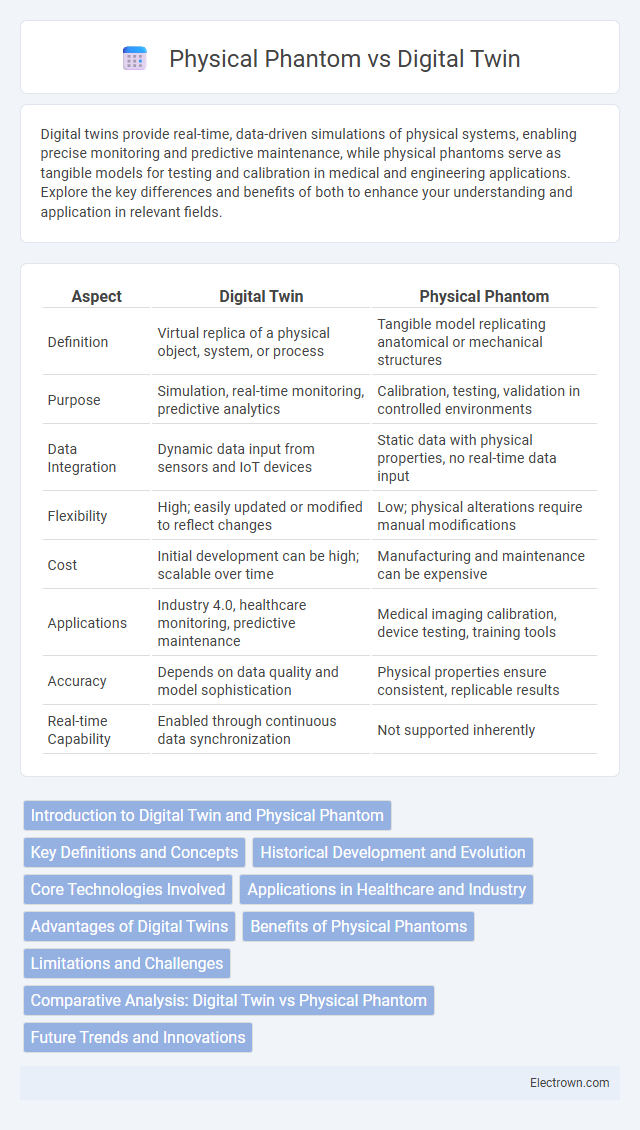

Digital twins provide real-time, data-driven simulations of physical systems, enabling precise monitoring and predictive maintenance, while physical phantoms serve as tangible models for testing and calibration in medical and engineering applications. Explore the key differences and benefits of both to enhance your understanding and application in relevant fields.

Table of Comparison

| Aspect | Digital Twin | Physical Phantom |

|---|---|---|

| Definition | Virtual replica of a physical object, system, or process | Tangible model replicating anatomical or mechanical structures |

| Purpose | Simulation, real-time monitoring, predictive analytics | Calibration, testing, validation in controlled environments |

| Data Integration | Dynamic data input from sensors and IoT devices | Static data with physical properties, no real-time data input |

| Flexibility | High; easily updated or modified to reflect changes | Low; physical alterations require manual modifications |

| Cost | Initial development can be high; scalable over time | Manufacturing and maintenance can be expensive |

| Applications | Industry 4.0, healthcare monitoring, predictive maintenance | Medical imaging calibration, device testing, training tools |

| Accuracy | Depends on data quality and model sophistication | Physical properties ensure consistent, replicable results |

| Real-time Capability | Enabled through continuous data synchronization | Not supported inherently |

Introduction to Digital Twin and Physical Phantom

Digital Twin represents a dynamic, virtual replica of a physical asset or system, continuously updated with real-time data to simulate and predict behavior. Physical Phantom refers to a tangible model, often used in medical imaging or engineering, designed for experimental testing and validation under controlled conditions. Both serve critical roles in simulation and analysis but differ in their application scope, with Digital Twins emphasizing real-time interaction and Physical Phantoms focusing on physical experimentation.

Key Definitions and Concepts

A Digital Twin is a virtual replica of a physical system that uses real-time data and simulation models to mirror, predict, and optimize operations, enabling enhanced decision-making and performance analysis. A Physical Phantom is a tangible model designed to mimic the physical properties and behaviors of a real object or biological tissue, primarily used for calibration, testing, and validation in experimental setups. Understanding these concepts highlights the contrast between dynamic, data-driven virtual representations and static, physical analogs for experimental accuracy.

Historical Development and Evolution

Digital twins originated in the early 2000s as virtual replicas of physical systems, evolving through advancements in IoT, AI, and data analytics to enable real-time monitoring and predictive maintenance. Physical phantoms, rooted in medical and engineering applications since the mid-20th century, provided tangible models for testing and calibration before digital simulation became prevalent. The evolution of digital twins reflects a shift towards dynamic, data-driven environments, while physical phantoms remain critical for validation and hands-on experimentation.

Core Technologies Involved

Digital Twins leverage IoT sensors, real-time data analytics, and advanced simulation software to create dynamic virtual representations of physical assets. Physical Phantoms rely on precise material engineering, 3D printing, and physical modeling techniques to replicate anatomical structures or mechanical systems for testing and calibration. Both technologies integrate AI and machine learning algorithms to enhance predictive accuracy and performance optimization.

Applications in Healthcare and Industry

Digital twins simulate real-world healthcare environments and industrial systems, enabling predictive maintenance, personalized treatment plans, and enhanced operational efficiency. Physical phantoms provide accurate anatomical or mechanical replicas used for calibration, training, and validation in medical imaging and manufacturing quality control. Your choice between digital twin and physical phantom depends on the need for dynamic data interaction or tangible model testing in your healthcare or industrial application.

Advantages of Digital Twins

Digital Twins offer real-time data synchronization and predictive analytics that enhance decision-making accuracy compared to Physical Phantoms, which rely on static models. They enable continuous monitoring and simulation of complex systems, allowing you to optimize performance, detect faults early, and reduce operational costs efficiently. The scalability and remote accessibility of Digital Twins also provide significant advantages for dynamic environments and innovative testing scenarios.

Benefits of Physical Phantoms

Physical phantoms provide tangible, real-world models that enable accurate calibration and validation of medical imaging devices and procedures, ensuring precision in diagnostics. Their consistent and reproducible material properties facilitate reliable quality assurance and safety testing across various medical applications. Unlike digital twins, physical phantoms allow direct experimental interaction, critical for hands-on training and device performance evaluation under controlled but realistic conditions.

Limitations and Challenges

Digital twins face limitations such as high computational costs, data integration complexity, and difficulties in maintaining real-time synchronization with physical assets. Physical phantoms are constrained by their static nature, lack of adaptability, and limited ability to replicate dynamic biological or environmental processes accurately. Both technologies encounter challenges in ensuring accuracy, scalability, and cost-effectiveness for diverse applications in healthcare, engineering, and manufacturing.

Comparative Analysis: Digital Twin vs Physical Phantom

Digital Twin technology offers real-time data integration and dynamic simulation capabilities that physical phantoms cannot replicate, enabling continuous monitoring and predictive maintenance in industries like healthcare and manufacturing. Physical phantoms provide tangible, controlled environments essential for calibration, validation, and training purposes, often used in medical imaging and radiation therapy for accurate dose measurements. While Digital Twins excel in virtual experimentation and scalability, physical phantoms remain critical for empirical validation and hands-on testing, highlighting their complementary roles in precision engineering and diagnostics.

Future Trends and Innovations

Emerging trends in digital twin technology emphasize real-time data integration and AI-driven predictive analytics, enabling more accurate and dynamic simulations compared to traditional physical phantoms. Innovations in sensor technology and cloud computing enhance digital twin scalability and remote accessibility, driving their adoption in complex system monitoring and medical diagnostics. Future developments will likely focus on hybrid models combining physical phantoms with digital twins for improved validation and training applications.

Digital Twin vs Physical Phantom Infographic

electrown.com

electrown.com