Resistive touch interfaces operate by detecting pressure applied to the screen, making them compatible with any input device, while capacitive touchscreens rely on the electrical properties of the human body for more responsive and multi-touch functionality. Discover the key benefits and limitations of each technology to help you choose the best interface for your device.

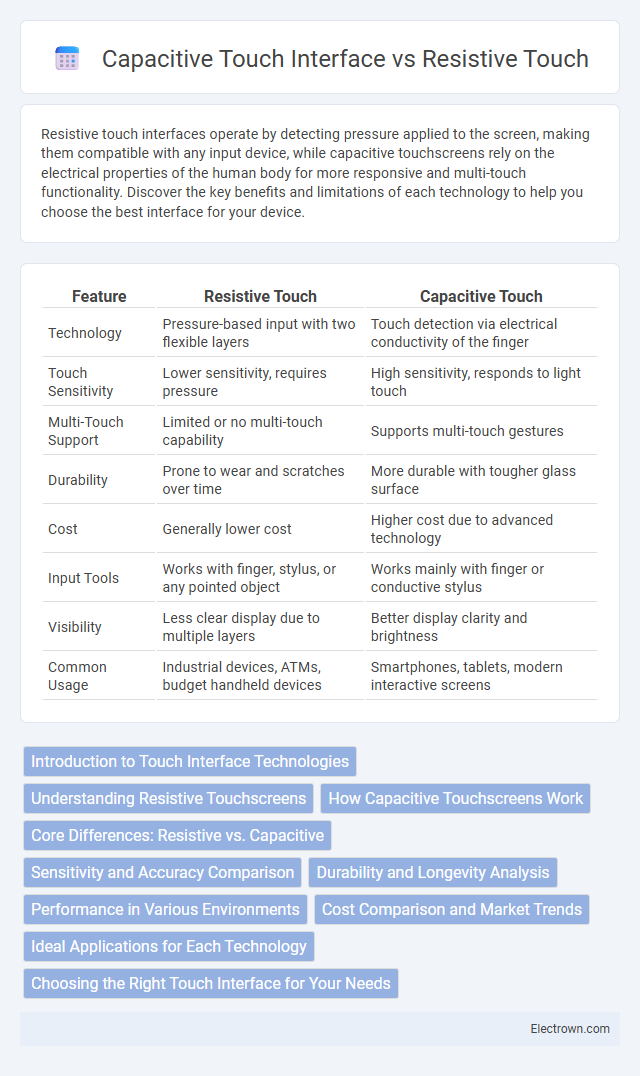

Table of Comparison

| Feature | Resistive Touch | Capacitive Touch |

|---|---|---|

| Technology | Pressure-based input with two flexible layers | Touch detection via electrical conductivity of the finger |

| Touch Sensitivity | Lower sensitivity, requires pressure | High sensitivity, responds to light touch |

| Multi-Touch Support | Limited or no multi-touch capability | Supports multi-touch gestures |

| Durability | Prone to wear and scratches over time | More durable with tougher glass surface |

| Cost | Generally lower cost | Higher cost due to advanced technology |

| Input Tools | Works with finger, stylus, or any pointed object | Works mainly with finger or conductive stylus |

| Visibility | Less clear display due to multiple layers | Better display clarity and brightness |

| Common Usage | Industrial devices, ATMs, budget handheld devices | Smartphones, tablets, modern interactive screens |

Introduction to Touch Interface Technologies

Resistive touch interfaces operate through pressure applied to two flexible layers that close an electrical circuit, enabling input detection on various surfaces, including stylus or gloved fingers. Capacitive touch technology relies on the electrical properties of the human body, detecting changes in capacitance on a conductive surface, which allows for multi-touch gestures and higher sensitivity. Your choice between resistive and capacitive touch depends on the application's requirements for accuracy, durability, and interaction methods.

Understanding Resistive Touchscreens

Resistive touchscreens consist of multiple layers, including two thin, electrically conductive layers separated by a narrow gap that register touch through pressure when these layers make contact. This technology allows input from any object, such as a finger, stylus, or gloved hand, making resistive screens versatile for various environments. Despite lower sensitivity and multi-touch capabilities compared to capacitive touchscreens, resistive interfaces excel in durability and cost-effectiveness for industrial and outdoor applications.

How Capacitive Touchscreens Work

Capacitive touchscreens function by detecting changes in the electrical field on a glass panel coated with a transparent conductor, such as indium tin oxide. When Your finger, which conducts electricity, touches the screen, it disrupts the local electrostatic field, allowing the device to register the precise touch location. This technology offers faster response times and supports multi-touch gestures, making it ideal for modern smartphones and tablets.

Core Differences: Resistive vs. Capacitive

Resistive touch interfaces operate through pressure sensitivity, registering input when two conductive layers make contact, making them functional with any pointing device such as fingers, styluses, or gloves. Capacitive touch interfaces detect touch through the electrical properties of the human body, responding only to conductive input like a bare finger, offering higher sensitivity and multi-touch capabilities. The core differences between resistive and capacitive touch screens lie in input method compatibility, durability, and responsiveness, with resistive favored for harsh environments and capacitive preferred for smoother, more precise user experiences.

Sensitivity and Accuracy Comparison

Capacitive touch interfaces offer higher sensitivity and accuracy compared to resistive touch screens due to their ability to detect even the slightest change in electrical charge from your finger. Resistive touch panels rely on pressure applied to the screen, resulting in lower precision and slower response times under light touches. For tasks demanding fine control and quick responsiveness, capacitive technology is generally the superior choice.

Durability and Longevity Analysis

Resistive touch interfaces, composed of multiple flexible layers, are more prone to wear and tear over time due to constant pressure causing membrane degradation, reducing durability and lifespan. Capacitive touch screens utilize a glass layer and electrostatic sensors, offering higher resistance to scratches and environmental factors, resulting in longer operational longevity. Your choice depends on the device environment, with capacitive interfaces favored for durability in high-use or outdoor conditions.

Performance in Various Environments

Resistive touch interfaces perform reliably in harsh environments, including exposure to dust, water, and extreme temperatures, making them ideal for industrial settings where durability is crucial. Capacitive touchscreens offer superior sensitivity and multi-touch capabilities but may struggle with performance when used with gloves or in wet conditions. Your choice depends on the operational environment, balancing precision and resistance to environmental factors for optimal device usability.

Cost Comparison and Market Trends

Resistive touch interfaces generally offer lower manufacturing costs due to simpler technology and materials, making them popular in budget-sensitive applications like industrial controls and medical devices. Capacitive touchscreens, though more expensive initially, dominate consumer electronics markets such as smartphones and tablets because of their superior sensitivity, multi-touch capabilities, and durability. Market trends indicate a growing shift toward capacitive touch technology driven by increasing demand for enhanced user experience, while resistive touch maintains relevance in rugged environments and cost-constrained markets.

Ideal Applications for Each Technology

Resistive touch interfaces excel in environments requiring high precision and durability, such as industrial machinery, medical devices, and outdoor kiosks, where gloves or styluses are often used. Capacitive touchscreens are ideal for consumer electronics like smartphones and tablets, offering multi-touch capability and enhanced sensitivity for finger input. Your choice depends on the application's need for accuracy, environmental exposure, and user interaction style.

Choosing the Right Touch Interface for Your Needs

Resistive touch interfaces offer precise input using any object and perform well in harsh environments, making them suitable for industrial applications and outdoor use. Capacitive touch interfaces provide multi-touch capability, higher sensitivity, and durability, ideal for consumer electronics and devices requiring smooth, responsive user experiences. Selecting the right touch interface depends on factors like usage conditions, input type, required sensitivity, and cost considerations.

Resistive Touch vs Capacitive Touch Interface Infographic

electrown.com

electrown.com