Unipolar stepper motors feature a simple winding configuration that allows for easier control and lower cost, while bipolar stepper motors provide higher torque and efficiency due to their more complex winding design. Explore how understanding these differences can enhance Your choice of the ideal stepper motor by reading the rest of this article.

Table of Comparison

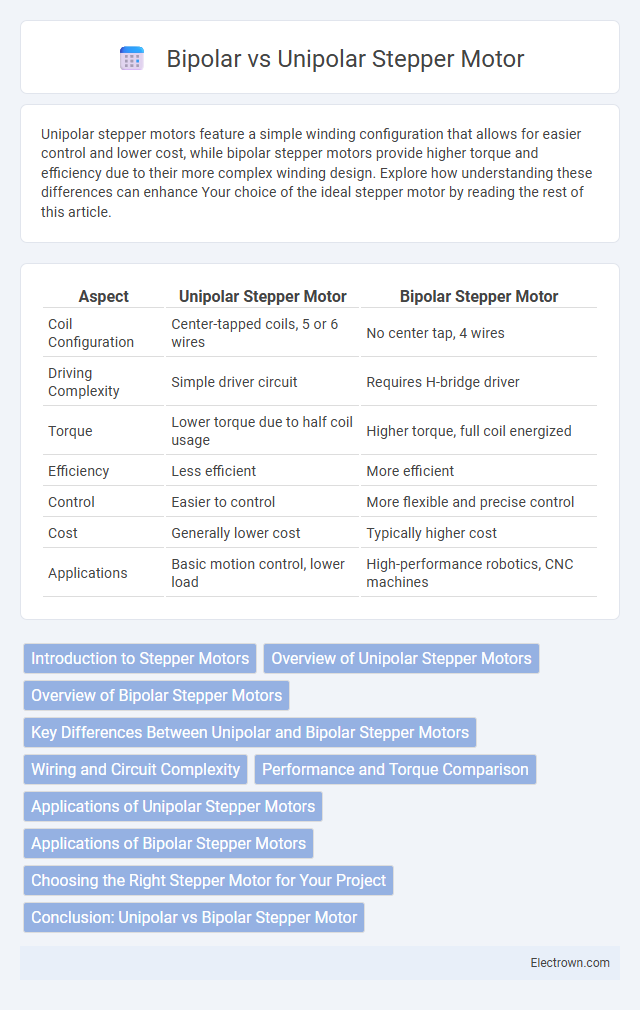

| Aspect | Unipolar Stepper Motor | Bipolar Stepper Motor |

|---|---|---|

| Coil Configuration | Center-tapped coils, 5 or 6 wires | No center tap, 4 wires |

| Driving Complexity | Simple driver circuit | Requires H-bridge driver |

| Torque | Lower torque due to half coil usage | Higher torque, full coil energized |

| Efficiency | Less efficient | More efficient |

| Control | Easier to control | More flexible and precise control |

| Cost | Generally lower cost | Typically higher cost |

| Applications | Basic motion control, lower load | High-performance robotics, CNC machines |

Introduction to Stepper Motors

Stepper motors convert electrical pulses into precise mechanical movements, commonly categorized into unipolar and bipolar types based on their winding configurations. Unipolar stepper motors feature center-tapped windings allowing simplified control with a single power supply, while bipolar stepper motors require current reversal for operation, enabling higher torque output. Understanding the fundamental differences in coil design and driving methods is critical for selecting the appropriate motor type in applications demanding accurate positioning and speed control.

Overview of Unipolar Stepper Motors

Unipolar stepper motors feature a center-tapped winding configuration that simplifies the driving circuitry by allowing current to flow in a single direction through each coil. This design enables faster switching and easier control using simple transistor arrays or driver ICs, making unipolar motors popular in low- to medium-torque applications. While they typically provide lower torque and less precision compared to bipolar stepper motors, their simplified control and reduced cost favor use in printers, scanners, and basic automation systems.

Overview of Bipolar Stepper Motors

Bipolar stepper motors use two coils per phase, requiring a more complex driver circuit capable of reversing current to achieve precise control. The motor's design delivers higher torque and efficiency compared to unipolar motors, making them ideal for applications demanding greater power and accuracy. Bipolar stepper motors are commonly employed in CNC machines, 3D printers, and robotics due to their superior performance and compact design.

Key Differences Between Unipolar and Bipolar Stepper Motors

Unipolar stepper motors feature a center-tapped winding, allowing current to flow in one direction per coil, which simplifies the driving circuitry but limits torque output compared to bipolar motors. Bipolar stepper motors use a single winding per phase with current reversed to change magnetic polarity, providing higher torque and efficiency at the cost of more complex drive electronics. Choosing between unipolar and bipolar stepper motors depends on Your application's torque requirements and available control hardware.

Wiring and Circuit Complexity

Unipolar stepper motors feature a simpler wiring scheme with five or six wires, allowing easier control circuits due to center-tapped coils that enable current flow direction change without reversing coil polarity. Bipolar stepper motors have four wires and require more complex driving circuits, often utilizing an H-bridge configuration to reverse current through the coils, offering greater torque and efficiency but necessitating advanced control logic. The wiring and circuit complexity differences significantly influence the choice of driver ICs and the overall system design in applications demanding precise motor control.

Performance and Torque Comparison

Bipolar stepper motors generally offer higher torque and better performance at low speeds due to their efficient current flow through the winding coils, providing stronger magnetic fields. Unipolar motors have simpler control circuits but produce less torque compared to bipolar motors, especially under heavy load conditions. Torque ripple in bipolar motors is often lower, resulting in smoother operation and improved precision in motion control applications.

Applications of Unipolar Stepper Motors

Unipolar stepper motors are commonly used in applications requiring precise control with simpler driver circuits, such as printers, scanners, and small robotics. Their ease of control and ability to provide reliable torque at low speeds make them ideal for consumer electronics and office automation devices. You will often find unipolar motors in film projectors and automated vending machines where straightforward, consistent step control is critical.

Applications of Bipolar Stepper Motors

Bipolar stepper motors are commonly used in applications requiring high torque and precise control, such as CNC machines, 3D printers, and robotic arms. Their ability to provide stronger magnetic fields allows for better performance in industrial automation and medical equipment. You will find bipolar stepper motors ideal for tasks demanding accurate positioning and reliable operation under heavy loads.

Choosing the Right Stepper Motor for Your Project

Unipolar stepper motors offer simpler control and faster response due to their center-tapped windings, making them ideal for projects requiring precise positioning with moderate torque. Bipolar stepper motors provide higher torque and efficiency since current flows through the entire winding, suitable for applications demanding power and accuracy. Consider your project's torque requirements, control complexity, and power supply constraints to select the most appropriate motor type for optimal performance.

Conclusion: Unipolar vs Bipolar Stepper Motor

Bipolar stepper motors offer higher torque and efficiency due to their simpler winding design and ability to utilize the full coil current, making them ideal for precision applications. Unipolar stepper motors present easier control with simpler driver circuits, suitable for cost-sensitive or less demanding projects. Your choice between unipolar and bipolar stepper motors depends on balancing torque requirements, control complexity, and budget constraints.

Unipolar vs Bipolar Stepper Motor Infographic

electrown.com

electrown.com