SSR (Solid State Relay) offers faster switching speed, longer lifespan, and silent operation compared to mechanical relays, which rely on physical contacts that can wear out over time and produce audible clicks. Explore the rest of the article to understand which relay best suits your specific application needs.

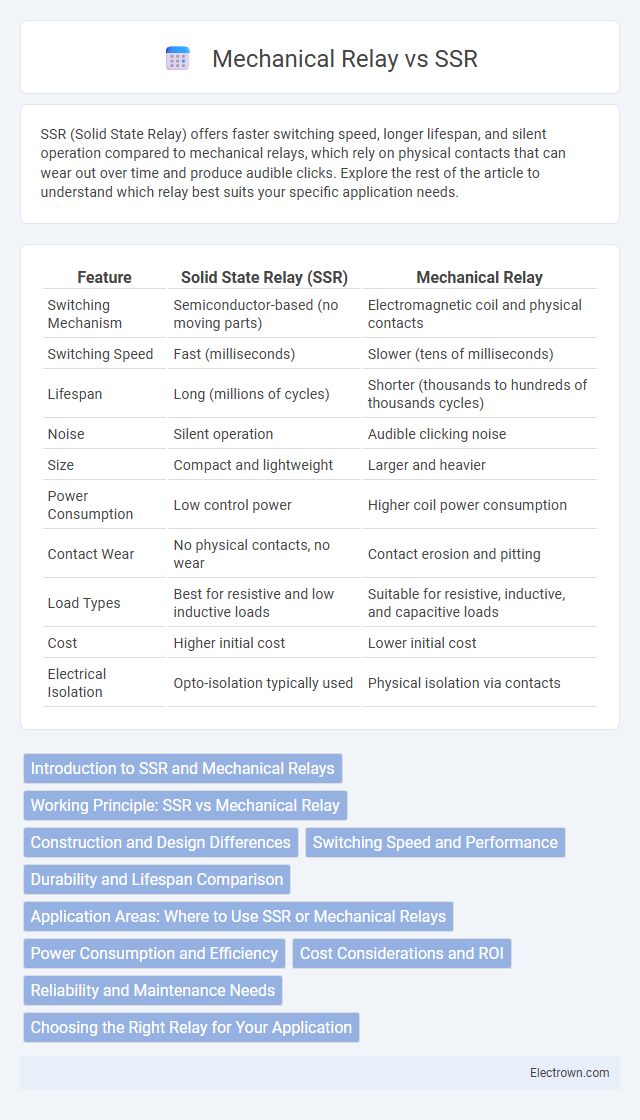

Table of Comparison

| Feature | Solid State Relay (SSR) | Mechanical Relay |

|---|---|---|

| Switching Mechanism | Semiconductor-based (no moving parts) | Electromagnetic coil and physical contacts |

| Switching Speed | Fast (milliseconds) | Slower (tens of milliseconds) |

| Lifespan | Long (millions of cycles) | Shorter (thousands to hundreds of thousands cycles) |

| Noise | Silent operation | Audible clicking noise |

| Size | Compact and lightweight | Larger and heavier |

| Power Consumption | Low control power | Higher coil power consumption |

| Contact Wear | No physical contacts, no wear | Contact erosion and pitting |

| Load Types | Best for resistive and low inductive loads | Suitable for resistive, inductive, and capacitive loads |

| Cost | Higher initial cost | Lower initial cost |

| Electrical Isolation | Opto-isolation typically used | Physical isolation via contacts |

Introduction to SSR and Mechanical Relays

Solid State Relays (SSRs) utilize semiconductor devices to switch electrical loads without moving parts, enabling faster switching speeds and enhanced durability compared to mechanical relays. Mechanical relays operate through an electromechanical mechanism, physically opening or closing contacts to control current flow, offering simplicity and low cost but limited lifespan due to contact wear. SSRs provide silent operation and reduced electrical noise, while mechanical relays excel in high surge current applications and provide clear visual status indicators.

Working Principle: SSR vs Mechanical Relay

Solid State Relays (SSR) operate using semiconductor devices such as thyristors, triacs, or transistors to switch electrical loads without moving parts, enabling faster and quieter switching with higher durability. Mechanical relays utilize an electromagnetic coil that physically moves contacts to open or close the circuit, resulting in slower switching speeds and susceptibility to mechanical wear. The absence of mechanical components in SSRs provides superior lifespan and resistance to shock and vibration compared to the traditional mechanical relay's electromechanical switching mechanism.

Construction and Design Differences

Solid State Relays (SSRs) utilize semiconductor components such as thyristors, triacs, or transistors to switch electrical loads without moving parts, resulting in faster switching speeds and enhanced durability. Mechanical relays feature an electromagnet that physically moves a set of contacts to open or close circuits, which can lead to wear and reduced lifespan due to contact arcing and mechanical fatigue. The absence of mechanical movement in SSRs eliminates contact bounce and reduces electrical noise, contrasting with the inherently physical switching action in mechanical relays.

Switching Speed and Performance

Solid State Relays (SSRs) offer significantly faster switching speeds, often in the range of microseconds to milliseconds, compared to mechanical relays that typically switch within 5 to 20 milliseconds due to physical contact movement. SSRs provide superior performance in high-speed, high-frequency switching applications as they lack moving parts, resulting in less wear and longer operational lifespan. Mechanical relays are prone to contact bounce and slower response times, making SSRs more reliable for precision timing and rapid on/off cycling in industrial automation and electronic systems.

Durability and Lifespan Comparison

Solid State Relays (SSRs) offer significantly greater durability and lifespan compared to mechanical relays due to their lack of moving parts, reducing wear and tear from mechanical fatigue. Mechanical relays typically have a limited number of switching cycles, often around one million, while SSRs can achieve tens of millions or more without degradation. Your choice of relay can impact maintenance intervals and long-term reliability, especially in high-frequency switching applications.

Application Areas: Where to Use SSR or Mechanical Relays

Solid State Relays (SSRs) are ideal for applications requiring high-speed switching, silent operation, and enhanced durability in environments like industrial automation, HVAC systems, and electronic devices. Mechanical relays excel in circuits needing high current capacity, robust reliability, and simple control, often found in automotive systems, power distribution, and heavy-duty machinery. Selecting SSRs or mechanical relays depends on factors such as switching frequency, load type, voltage levels, and environmental conditions.

Power Consumption and Efficiency

Solid State Relays (SSRs) consume significantly less power than mechanical relays because they have no moving parts and generate minimal heat during operation, leading to higher energy efficiency. Mechanical relays require more power to energize their coils and suffer from higher energy losses due to physical contact resistance and friction. Choosing an SSR can improve your system's overall efficiency and reduce power consumption, especially in applications with frequent switching.

Cost Considerations and ROI

Solid State Relays (SSRs) typically have a higher upfront cost compared to mechanical relays due to their advanced semiconductor components and longer lifespan. However, SSRs offer superior durability, faster switching speeds, and reduced maintenance expenses, leading to a better return on investment (ROI) over time. Your choice between SSR and mechanical relays should weigh initial expenditure against long-term savings, especially in high-cycle or critical applications.

Reliability and Maintenance Needs

Solid State Relays (SSRs) offer superior reliability compared to mechanical relays due to their lack of moving parts, reducing wear and tear significantly. Mechanical relays require regular maintenance because their contacts can degrade over time, leading to potential failure or inconsistent performance. Your system benefits from SSRs through lower maintenance demands and enhanced operational lifespan, making them ideal for applications needing continual, reliable switching.

Choosing the Right Relay for Your Application

Solid State Relays (SSRs) offer faster switching speeds, longer lifespans, and noiseless operation compared to mechanical relays, making them ideal for applications requiring high-frequency switching or silent performance. Mechanical relays provide better electrical isolation and handle higher surge currents, suitable for heavy-duty industrial equipment where robustness and thermal management are critical. Understanding your application's load characteristics, switching frequency, and environmental conditions will help you choose the right relay that ensures optimal reliability and efficiency in your system.

SSR vs mechanical relay Infographic

electrown.com

electrown.com