Absolute encoders provide unique position values for each shaft rotation, ensuring precise position tracking even after power loss, while incremental encoders generate relative position signals that require a reference point for accurate measurement. Explore the differences and advantages of each encoder type to determine which solution best fits Your application needs in the rest of this article.

Table of Comparison

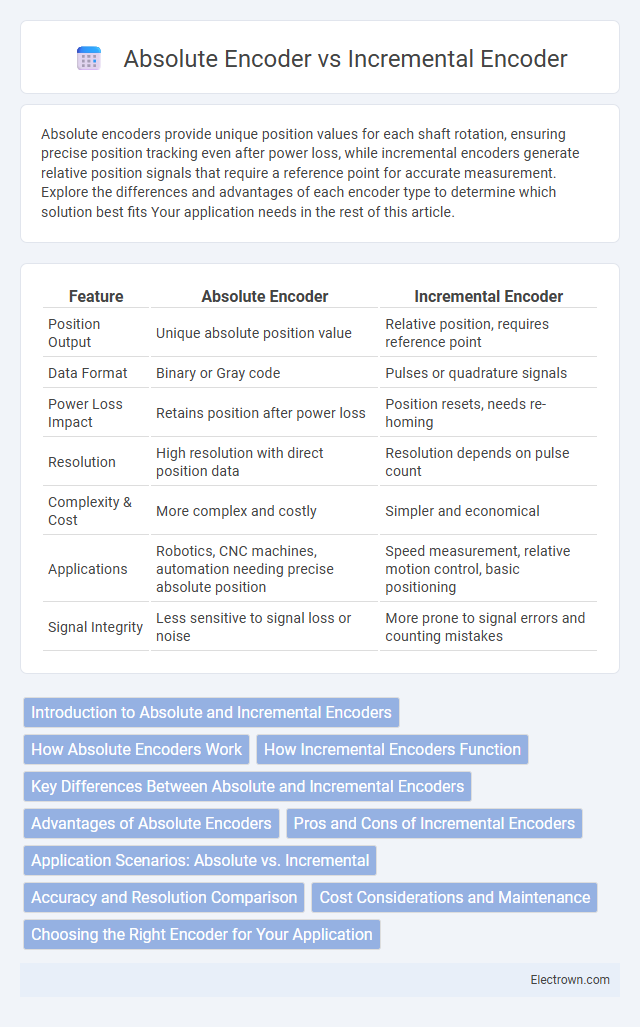

| Feature | Absolute Encoder | Incremental Encoder |

|---|---|---|

| Position Output | Unique absolute position value | Relative position, requires reference point |

| Data Format | Binary or Gray code | Pulses or quadrature signals |

| Power Loss Impact | Retains position after power loss | Position resets, needs re-homing |

| Resolution | High resolution with direct position data | Resolution depends on pulse count |

| Complexity & Cost | More complex and costly | Simpler and economical |

| Applications | Robotics, CNC machines, automation needing precise absolute position | Speed measurement, relative motion control, basic positioning |

| Signal Integrity | Less sensitive to signal loss or noise | More prone to signal errors and counting mistakes |

Introduction to Absolute and Incremental Encoders

Absolute encoders provide unique position values for each shaft angle, delivering precise and consistent feedback even after power loss, making them ideal for applications requiring exact positioning. Incremental encoders generate relative position signals through pulses, which must be counted from a known reference point, offering simplicity and cost-effectiveness for motion control tasks. Your choice between absolute and incremental encoders depends on the need for position accuracy, reliability, and system complexity.

How Absolute Encoders Work

Absolute encoders work by generating a unique code for each shaft position, allowing accurate and immediate determination of the angle without needing a reference point. Their optical or magnetic sensors read a coded disk or magnetic pattern that provides a specific digital value representing the exact position. This feature ensures your system maintains position information even during power loss, enhancing precision and reliability.

How Incremental Encoders Function

Incremental encoders function by generating a series of pulses as a shaft rotates, with each pulse corresponding to a specific movement increment. These pulses are counted by a controller to determine the relative position, speed, or direction of the rotating object. Unlike absolute encoders, they do not provide a unique position value at power-up and require a reference point to establish an initial position.

Key Differences Between Absolute and Incremental Encoders

Absolute encoders provide unique position values for each shaft angle, enabling precise position tracking even after power loss, whereas incremental encoders output relative position changes from a reference point, requiring a homing procedure at startup. Absolute encoders use binary or gray code signals to represent exact angular positions, while incremental encoders generate pulse counts to measure displacement or speed. The primary difference lies in data retention and position resolution; absolute encoders offer non-volatile position information, ideal for complex motion control, whereas incremental encoders are simpler and cost-effective for applications where position resetting is acceptable.

Advantages of Absolute Encoders

Absolute encoders provide precise position information by delivering a unique code for each shaft position, ensuring accurate tracking even after power loss. Their ability to maintain position data without requiring a reference move enhances reliability in complex automation systems. You benefit from reduced downtime and improved operational efficiency when using absolute encoders in critical applications.

Pros and Cons of Incremental Encoders

Incremental encoders offer high resolution and cost-effectiveness, making them ideal for applications requiring precise position feedback with limited budget constraints. Their main drawback is the need for a reference point or home sensor to determine absolute position after power loss, leading to potential errors in position tracking. Maintenance complexity can increase in environments with electrical noise, as incremental signals are more susceptible to interference compared to absolute encoders.

Application Scenarios: Absolute vs. Incremental

Absolute encoders are ideal for applications requiring precise position tracking and power cycle recovery, such as robotics, CNC machinery, and industrial automation where exact shaft location must be known at all times. Incremental encoders suit high-speed motion control and feedback in conveyor systems, elevators, and simple motor control, where relative position and speed are more critical than absolute position. The choice depends on factors like system complexity, cost, and the necessity for position accuracy after power loss.

Accuracy and Resolution Comparison

Absolute encoders provide higher accuracy and resolution by delivering a unique position value for each shaft angle, ensuring precise angle measurement without cumulative error. Incremental encoders offer relative position data with resolution dependent on pulse count per revolution, but can suffer from position loss during power outages or signal interruptions. Absolute encoders typically achieve resolutions up to 23 bits per revolution, while incremental encoders commonly range between 8 to 16 bits, making absolutes more suitable for high-precision applications.

Cost Considerations and Maintenance

Absolute encoders typically have higher initial costs due to their complex design and integrated memory, but they reduce maintenance expenses by providing precise position data even after power loss, minimizing downtime. Incremental encoders are generally more affordable upfront but may incur higher maintenance costs as they require regular calibration and can lose position tracking during power interruptions. Your choice should balance budget constraints with long-term reliability and maintenance needs for optimal performance.

Choosing the Right Encoder for Your Application

Absolute encoders provide unique position values for each shaft angle, ensuring precise and reliable feedback crucial for applications requiring exact positioning and power recovery during power interruptions. Incremental encoders offer high-resolution relative position data ideal for speed control and applications where cost-efficiency and simplicity take precedence. Selecting the right encoder depends on factors like required accuracy, environmental conditions, system complexity, and budget constraints, making absolute encoders suitable for robotics and automation, while incremental encoders excel in conveyor systems and motor feedback.

Absolute Encoder vs Incremental Encoder Infographic

electrown.com

electrown.com