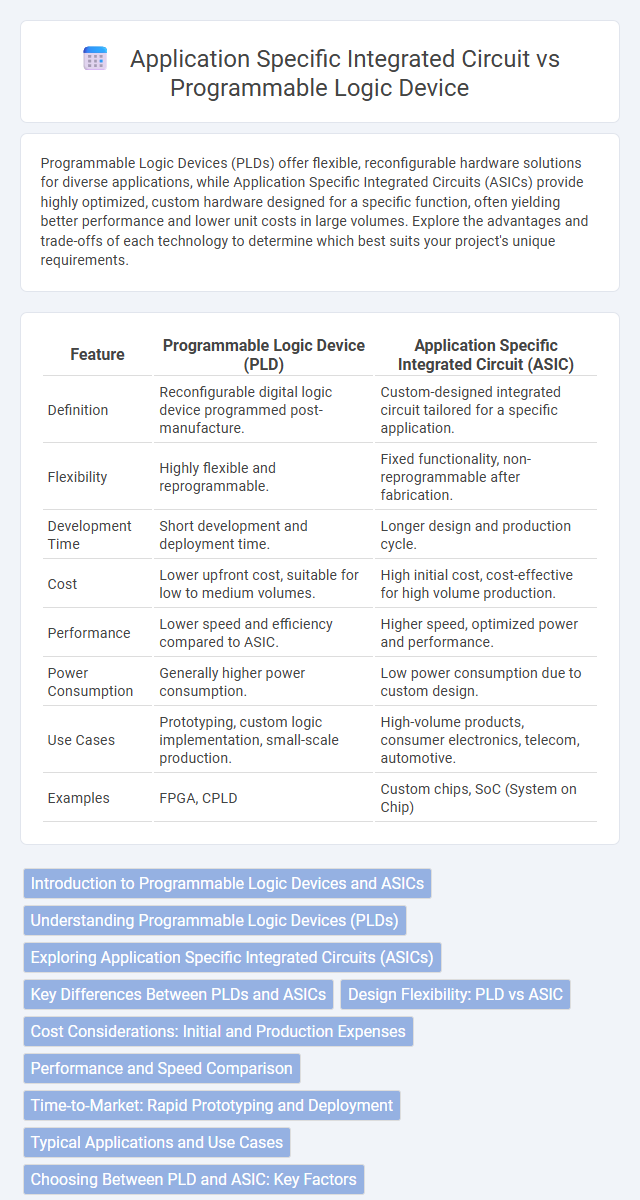

Programmable Logic Devices (PLDs) offer flexible, reconfigurable hardware solutions for diverse applications, while Application Specific Integrated Circuits (ASICs) provide highly optimized, custom hardware designed for a specific function, often yielding better performance and lower unit costs in large volumes. Explore the advantages and trade-offs of each technology to determine which best suits your project's unique requirements.

Table of Comparison

| Feature | Programmable Logic Device (PLD) | Application Specific Integrated Circuit (ASIC) |

|---|---|---|

| Definition | Reconfigurable digital logic device programmed post-manufacture. | Custom-designed integrated circuit tailored for a specific application. |

| Flexibility | Highly flexible and reprogrammable. | Fixed functionality, non-reprogrammable after fabrication. |

| Development Time | Short development and deployment time. | Longer design and production cycle. |

| Cost | Lower upfront cost, suitable for low to medium volumes. | High initial cost, cost-effective for high volume production. |

| Performance | Lower speed and efficiency compared to ASIC. | Higher speed, optimized power and performance. |

| Power Consumption | Generally higher power consumption. | Low power consumption due to custom design. |

| Use Cases | Prototyping, custom logic implementation, small-scale production. | High-volume products, consumer electronics, telecom, automotive. |

| Examples | FPGA, CPLD | Custom chips, SoC (System on Chip) |

Introduction to Programmable Logic Devices and ASICs

Programmable Logic Devices (PLDs) are customizable semiconductor devices that allow you to configure hardware logic functions after manufacturing, offering flexibility for various digital applications. Application Specific Integrated Circuits (ASICs) are custom-designed chips tailored for a specific application, providing higher performance and efficiency but lacking post-production reconfigurability. Understanding the key differences between PLDs and ASICs helps in selecting the right solution for your project's scalability and cost requirements.

Understanding Programmable Logic Devices (PLDs)

Programmable Logic Devices (PLDs) are semiconductor devices that can be customized by the user to implement specific logical functions, offering flexibility in digital circuit design. Unlike Application Specific Integrated Circuits (ASICs), which are pre-designed for a fixed function, PLDs enable rapid prototyping and modification through programming. Key types of PLDs include Programmable Array Logic (PAL), Generic Array Logic (GAL), and Complex Programmable Logic Devices (CPLDs), each varying in complexity and capacity for logic implementation.

Exploring Application Specific Integrated Circuits (ASICs)

Application Specific Integrated Circuits (ASICs) are custom-designed hardware components tailored for specific tasks, offering higher performance and lower power consumption compared to Programmable Logic Devices (PLDs). ASICs enable optimized circuit designs that maximize efficiency in applications such as consumer electronics, telecommunications, and automotive systems. The development cost of ASICs is higher, but their non-reprogrammable nature and superior speed make them ideal for large-scale production requiring specialized functionality.

Key Differences Between PLDs and ASICs

Programmable Logic Devices (PLDs) offer flexibility and reprogrammability for designing digital circuits, allowing multiple iterations and custom logic modifications, whereas Application Specific Integrated Circuits (ASICs) provide optimized performance with fixed functionality tailored for high-volume production. PLDs typically involve lower non-recurring engineering (NRE) costs and faster time-to-market, while ASICs require significant upfront design investment but yield superior power efficiency, speed, and integration density. The choice between PLDs and ASICs depends on factors such as production scale, required customization, development time, and cost constraints.

Design Flexibility: PLD vs ASIC

Programmable Logic Devices (PLDs) offer superior design flexibility by allowing designers to reprogram and modify the logic functions after manufacturing, which accelerates development cycles and supports iterative design changes. Application Specific Integrated Circuits (ASICs) provide high performance and lower unit cost for large production volumes but lack post-fabrication reconfigurability, requiring fixed, custom hardware tailored to a specific application. The trade-off between PLDs and ASICs centers on flexibility and time-to-market advantages against performance optimization and cost efficiency in mass production.

Cost Considerations: Initial and Production Expenses

Programmable Logic Devices (PLDs) have lower initial costs due to their reusability and faster development cycles, making them ideal for prototyping and low-volume production. Application Specific Integrated Circuits (ASICs) require substantial upfront investment in design and manufacturing, but they offer lower per-unit costs in high-volume production runs. You should weigh your project's scale and budget constraints when deciding between the flexible, cost-effective PLD and the high-efficiency, cost-saving ASIC for mass production.

Performance and Speed Comparison

Programmable Logic Devices (PLDs) offer flexible configurations but generally operate at lower speeds compared to Application Specific Integrated Circuits (ASICs), which are designed for optimized performance in specific tasks. ASICs achieve higher processing speeds and improved power efficiency due to their customized architecture, making them ideal for high-performance applications. Your choice between PLD and ASIC will depend on the balance you require between design flexibility and maximum operational speed.

Time-to-Market: Rapid Prototyping and Deployment

Programmable Logic Devices (PLDs) offer significantly faster time-to-market by enabling rapid prototyping and iterative design changes without the need for custom manufacturing. Application Specific Integrated Circuits (ASICs) require extensive design, verification, and fabrication processes, leading to longer deployment cycles and higher upfront costs. Your product development benefits from the flexibility of PLDs when quick updates and shorter market entry are critical.

Typical Applications and Use Cases

Programmable Logic Devices (PLDs) are widely used in prototyping, custom hardware solutions, and low-to-medium volume production where flexibility and rapid development are critical, such as in industrial automation, consumer electronics, and telecommunication systems. Application Specific Integrated Circuits (ASICs) dominate high-volume manufacturing environments requiring optimized performance, power efficiency, and reduced unit cost, making them ideal for smartphones, automotive electronics, and large-scale data centers. PLDs excel in iterative design phases and adaptable system requirements, while ASICs are preferred for mass production with fixed functionalities.

Choosing Between PLD and ASIC: Key Factors

When choosing between a Programmable Logic Device (PLD) and an Application Specific Integrated Circuit (ASIC), consider factors such as design flexibility, production volume, and development cost. PLDs offer rapid prototyping and easy reconfiguration for lower-volume projects, while ASICs provide optimized performance and cost-efficiency for large-scale manufacturing. Your decision should weigh time-to-market needs against long-term unit costs and customization requirements.

Programmable Logic Device vs Application Specific Integrated Circuit Infographic

electrown.com

electrown.com