PWM resolution defines the precision of duty cycle adjustment, influencing how finely you can control power delivery, while PWM frequency determines how fast the signal switches on and off, affecting the smoothness and efficiency of your system. Explore the rest of the article to understand how balancing these two factors impacts your application's performance.

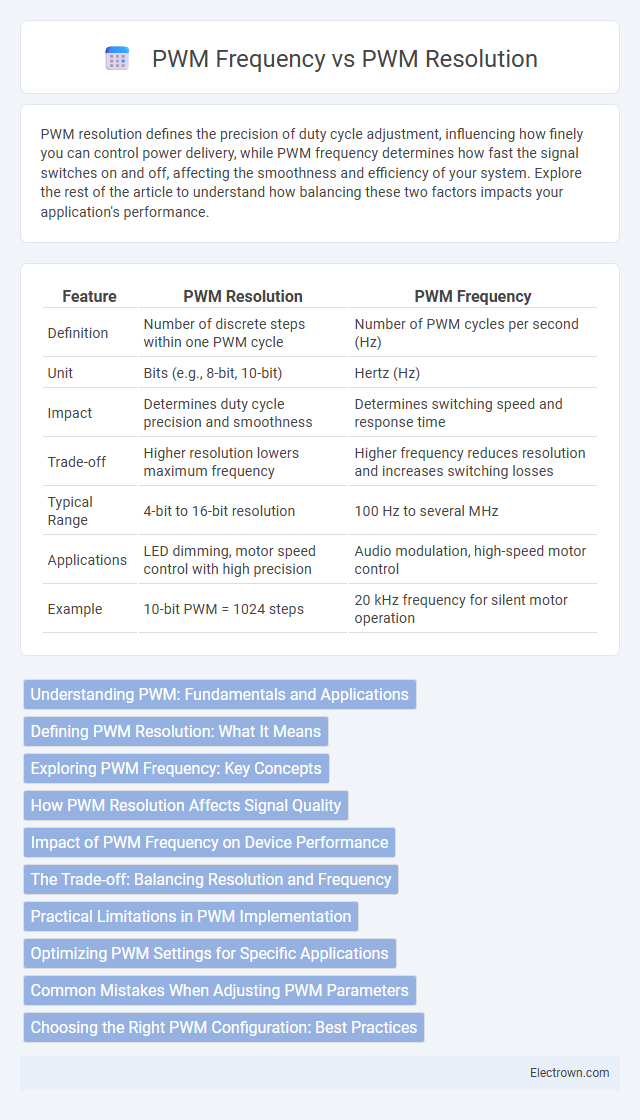

Table of Comparison

| Feature | PWM Resolution | PWM Frequency |

|---|---|---|

| Definition | Number of discrete steps within one PWM cycle | Number of PWM cycles per second (Hz) |

| Unit | Bits (e.g., 8-bit, 10-bit) | Hertz (Hz) |

| Impact | Determines duty cycle precision and smoothness | Determines switching speed and response time |

| Trade-off | Higher resolution lowers maximum frequency | Higher frequency reduces resolution and increases switching losses |

| Typical Range | 4-bit to 16-bit resolution | 100 Hz to several MHz |

| Applications | LED dimming, motor speed control with high precision | Audio modulation, high-speed motor control |

| Example | 10-bit PWM = 1024 steps | 20 kHz frequency for silent motor operation |

Understanding PWM: Fundamentals and Applications

PWM resolution determines the number of discrete voltage levels you can achieve by controlling the duty cycle, directly impacting the smoothness and precision of your signal. PWM frequency defines how fast these pulses switch on and off, influencing response time and compatibility with different devices or applications. Balancing PWM resolution and frequency is crucial for optimizing performance in motor control, LED dimming, and power regulation systems.

Defining PWM Resolution: What It Means

PWM resolution refers to the number of discrete voltage levels a Pulse Width Modulation (PWM) signal can produce, directly impacting the granularity of control over the output waveform. Higher resolution enables finer adjustments in duty cycle, resulting in more precise control of motor speed, LED brightness, or other applications using PWM signals. The resolution is typically measured in bits, where an n-bit resolution corresponds to 2^n possible duty cycle steps.

Exploring PWM Frequency: Key Concepts

PWM frequency determines how fast the pulse width modulation signal cycles per second, directly influencing the smoothness and precision of motor or LED control. Higher PWM frequencies typically result in finer resolution and reduced audible noise, but may increase power consumption and require more advanced hardware capabilities. Understanding the balance between PWM resolution and frequency enables you to optimize performance for specific applications, such as minimizing flicker or achieving precise speed control.

How PWM Resolution Affects Signal Quality

Higher PWM resolution increases the number of discrete duty cycle steps, enabling finer control over signal modulation and resulting in smoother output waveforms. This improved granularity reduces harmonic distortion and electromagnetic interference (EMI), enhancing overall signal quality. Conversely, lower resolution PWM signals exhibit more noticeable quantization noise and voltage ripple, deteriorating precision in applications such as motor control and LED dimming.

Impact of PWM Frequency on Device Performance

PWM frequency directly influences device performance by affecting signal precision and electromagnetic interference (EMI). Higher PWM frequencies enable finer control and smoother operation in motors and LEDs but can increase switching losses and heat generation. Balancing PWM resolution and frequency is crucial to optimize efficiency, minimize noise, and maintain device longevity.

The Trade-off: Balancing Resolution and Frequency

Higher PWM resolution increases the number of duty cycle steps, allowing finer control over your device's output but requires a lower PWM frequency to maintain signal integrity. Conversely, raising the PWM frequency reduces resolution, limiting the granularity of your control but benefits applications needing faster response times. Balancing PWM resolution and frequency involves optimizing your system's performance requirements without compromising signal quality or control precision.

Practical Limitations in PWM Implementation

PWM resolution and PWM frequency are inversely related in practical implementations, as increasing frequency typically reduces resolution due to limited timer counts. Your choice of microcontroller or timer peripheral directly affects achievable resolution and frequency, with hardware constraints such as clock speed and timer bit length imposing strict limits. Thermal and electromagnetic interference issues also arise at higher frequencies, impacting signal integrity and overall system performance.

Optimizing PWM Settings for Specific Applications

Optimizing PWM settings for specific applications requires balancing PWM resolution and frequency to achieve precise control and efficient performance. Higher PWM resolution allows finer adjustments in duty cycle, critical for applications like LED dimming or motor control, while higher PWM frequency reduces audible noise and improves response time. You should tailor PWM resolution and frequency based on the device's requirements, ensuring smooth operation without sacrificing accuracy or generating unnecessary electromagnetic interference.

Common Mistakes When Adjusting PWM Parameters

Common mistakes when adjusting PWM parameters include neglecting the impact of resolution on frequency accuracy, leading to signal distortion or unexpected behavior in motor control applications. Setting a high PWM frequency with low resolution can cause insufficient duty cycle granularity, resulting in unstable output voltage and increased electromagnetic interference (EMI). Overlooking the trade-off between PWM resolution and frequency often compromises system performance, especially in power electronics and LED dimming applications.

Choosing the Right PWM Configuration: Best Practices

Selecting the optimal PWM configuration requires balancing resolution and frequency to match your application's needs. Higher PWM resolution offers finer control over duty cycle, ideal for precise motor speed or LED brightness adjustments, while higher PWM frequency reduces audible noise and improves response time in switching circuits. Your choice should consider device limitations, thermal constraints, and the target system's sensitivity to switching frequency and control granularity for best performance.

PWM Resolution vs PWM Frequency Infographic

electrown.com

electrown.com