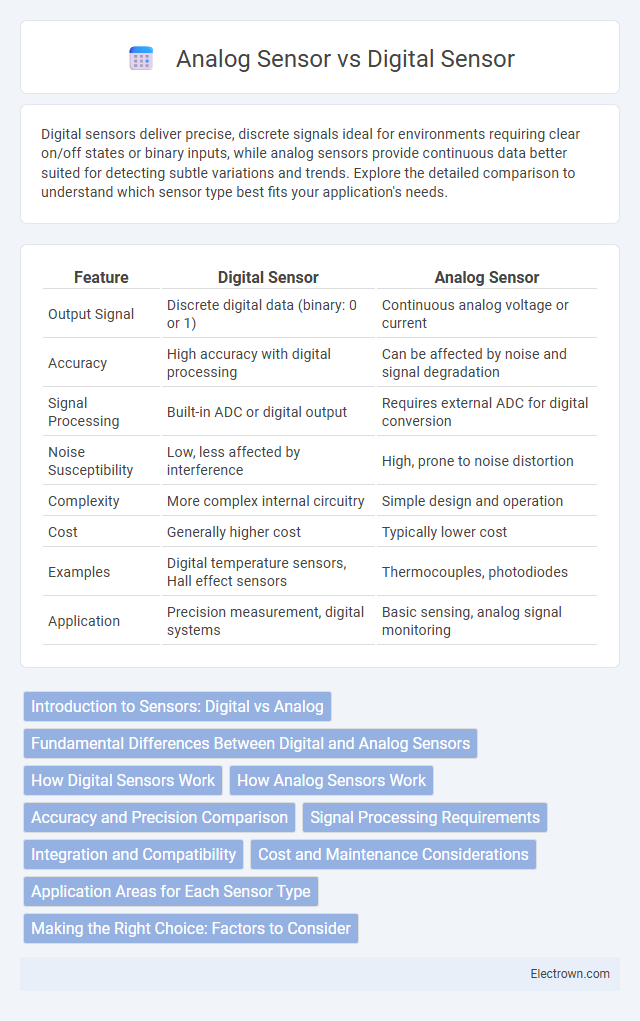

Digital sensors deliver precise, discrete signals ideal for environments requiring clear on/off states or binary inputs, while analog sensors provide continuous data better suited for detecting subtle variations and trends. Explore the detailed comparison to understand which sensor type best fits your application's needs.

Table of Comparison

| Feature | Digital Sensor | Analog Sensor |

|---|---|---|

| Output Signal | Discrete digital data (binary: 0 or 1) | Continuous analog voltage or current |

| Accuracy | High accuracy with digital processing | Can be affected by noise and signal degradation |

| Signal Processing | Built-in ADC or digital output | Requires external ADC for digital conversion |

| Noise Susceptibility | Low, less affected by interference | High, prone to noise distortion |

| Complexity | More complex internal circuitry | Simple design and operation |

| Cost | Generally higher cost | Typically lower cost |

| Examples | Digital temperature sensors, Hall effect sensors | Thermocouples, photodiodes |

| Application | Precision measurement, digital systems | Basic sensing, analog signal monitoring |

Introduction to Sensors: Digital vs Analog

Digital sensors convert physical parameters into discrete digital signals, offering precise and noise-resistant readings ideal for modern electronic systems. Analog sensors produce continuous voltage or current signals proportional to the measured variable, enabling real-time monitoring with high resolution but increased susceptibility to noise. Both sensor types serve distinct roles in applications like automation, environmental monitoring, and signal processing, where digital sensors excel in integration and analog sensors provide detailed signal fidelity.

Fundamental Differences Between Digital and Analog Sensors

Digital sensors provide discrete, binary output signals that represent precise on/off states or specific data values, making them ideal for digital systems and easy signal processing. Analog sensors generate continuous signals proportional to the measured physical quantity, offering detailed and nuanced information but requiring analog-to-digital conversion for digital interpretation. Your choice between digital and analog sensors depends on the required signal resolution, compatibility with processing units, and the nature of the measurement.

How Digital Sensors Work

Digital sensors convert physical quantities into discrete digital signals by using internal analog-to-digital converters (ADCs), enabling precise and noise-resistant data transmission. These sensors sample the input continuously and output binary values that represent measurable parameters such as temperature, pressure, or light intensity. The digital output allows direct interfacing with microcontrollers and digital systems for accurate processing and analysis.

How Analog Sensors Work

Analog sensors work by converting physical stimuli such as temperature, light, or pressure into continuous electrical signals that vary proportionally to the measured parameter. These sensors produce voltage or current outputs directly dependent on the intensity of the input, allowing precise real-time monitoring. Your system can interpret these varying signals to provide accurate analog data for analysis or control applications.

Accuracy and Precision Comparison

Digital sensors provide higher accuracy and precision by converting physical signals into discrete digital values, minimizing noise and signal degradation common in analog sensors. Analog sensors can suffer from signal distortion and require calibration to maintain precision, resulting in potential variability in measurement accuracy. Your choice depends on the application's need for exact data representation and environmental factors influencing sensor performance.

Signal Processing Requirements

Digital sensors convert physical signals into discrete digital values, simplifying signal processing by enabling direct integration with microcontrollers and digital systems without the need for complex filtering or amplification. Analog sensors output continuous signals that require more elaborate processing, including amplification, filtering, and analog-to-digital conversion before digital interpretation. Your choice between digital and analog sensors impacts the complexity and precision of the signal processing chain in your application.

Integration and Compatibility

Digital sensors offer seamless integration with modern microcontrollers and digital systems through standardized communication protocols like I2C, SPI, and UART, ensuring straightforward compatibility with your existing hardware. Analog sensors require analog-to-digital converters (ADCs) for compatibility with digital systems, which can add complexity and increase integration time. Choosing digital sensors simplifies data acquisition and reduces the need for additional components, enhancing overall system reliability and compatibility.

Cost and Maintenance Considerations

Digital sensors generally have higher initial costs due to integrated processing capabilities but offer lower long-term maintenance expenses owing to fewer calibration needs and improved signal stability. Analog sensors are typically less expensive upfront but may require frequent recalibration and maintenance because of signal drift and susceptibility to noise interference. Your choice between digital and analog sensors should factor in not only the upfront budget but also ongoing maintenance resources and operational reliability.

Application Areas for Each Sensor Type

Digital sensors excel in applications requiring precise data transmission and integration with microcontrollers, such as in consumer electronics, robotics, and automated industrial systems. Analog sensors are preferred in environments demanding continuous signal variation detection, including audio equipment, temperature monitoring, and environmental sensing. Both sensor types serve critical roles across automotive systems, healthcare devices, and smart home technologies, tailored by the specific requirements for signal processing and accuracy.

Making the Right Choice: Factors to Consider

Choosing between digital sensors and analog sensors depends on factors such as required signal precision, environmental noise tolerance, and data processing capabilities. Digital sensors provide discrete, noise-resistant outputs ideal for precise, binary data applications, while analog sensors offer continuous signals beneficial for capturing variable measurements. Consider the application context, compatibility with control systems, and the need for accuracy or flexibility when making the right sensor choice.

Digital Sensor vs Analog Sensor Infographic

electrown.com

electrown.com